| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

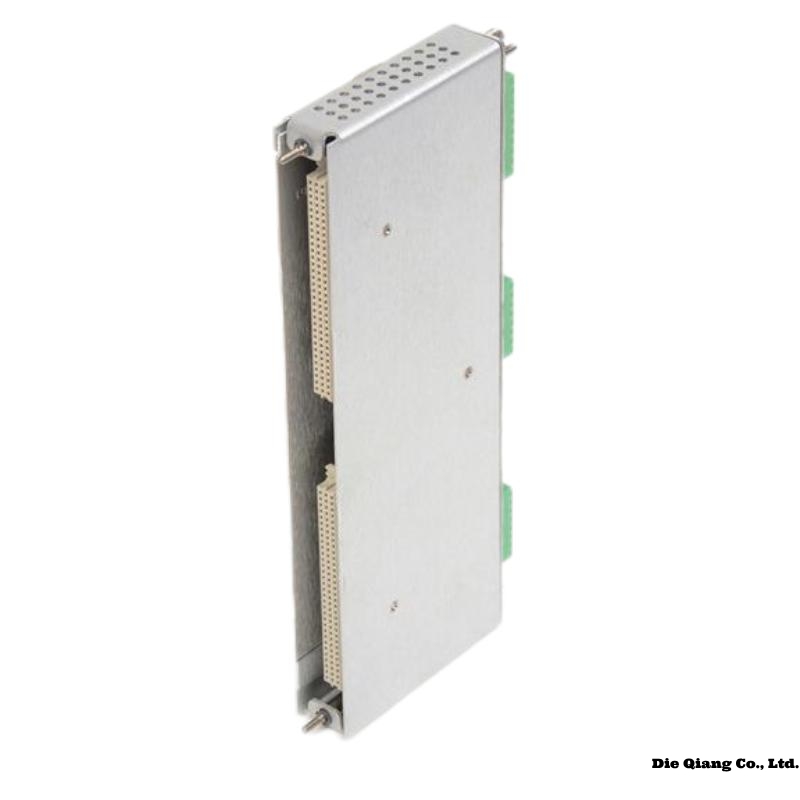

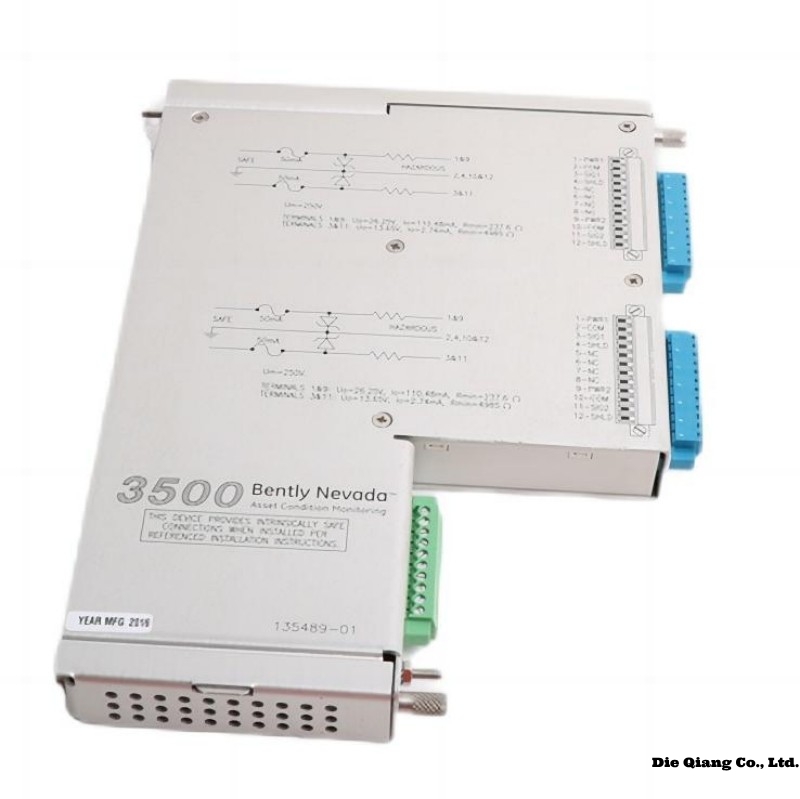

Product Introduction – Bently Nevada 3500/45-02-00 135145-01

The Bently Nevada 3500/45-02-00 135145-01 Position Monitor is a highly reliable module specifically designed for industrial monitoring of machine axial or radial positions. As a crucial component of the renowned 3500 Machinery Protection System, this module accurately measures and processes sensor signals to monitor shaft position or other mechanical movement parameters, ensuring early detection of abnormalities. It features dual-channel capability, dynamic alarm limits, and integrates seamlessly with the 3500 rack configuration, providing continuous protection and precise information to optimize machine health and performance.

This module plays a critical role in preventing catastrophic machinery failures, safeguarding assets, and extending machine lifespan across a wide range of industries including oil and gas, power generation, and petrochemical sectors.

Product Advantages – Bently Nevada 3500/45-02-00 135145-01

-

High Accuracy: Provides real-time, high-precision measurements of shaft or mechanical positions.

-

Dual-Channel Monitoring: Supports simultaneous independent monitoring of two channels to enhance system reliability.

-

Flexible Configuration: Compatible with multiple types of proximity transducers and position sensors.

-

Early Fault Detection: Dynamic alarm processing capabilities allow detection of minor issues before they escalate.

-

Easy Integration: Designed to integrate effortlessly into the 3500 monitoring system without additional modifications.

-

Enhanced Machine Protection: Helps to prevent unplanned outages and reduce maintenance costs through continuous monitoring.

-

Field-Proven Reliability: Built to withstand harsh industrial environments with proven stability and durability.

Technical Specifications – Bently Nevada 3500/45-02-00 135145-01

| Parameter | Details |

|---|---|

| Model | 3500/45-02-00 135145-01 |

| Input Channels | 2 independent channels |

| Measurement Type | Position (axial or radial) |

| Input Type | Proximity probes or other position sensors |

| Operating Voltage | +24 VDC (supplied from 3500 rack) |

| Dimensions | 241.3 x 24.4 x 99.1 mm |

| Weight | 0.20 kg |

| Alarm Setpoints | Configurable for each channel |

| Accuracy | ±0.25% of full scale |

| Mounting | 3500 Rack Slot |

| Communication Protocol | Proprietary (through Rack Interface) |

| Temperature Range | -30°C to +65°C (-22°F to +149°F) |

| Certifications | CE, CSA, ATEX, IECEx |

Applications – Bently Nevada 3500/45-02-00 135145-01

-

Steam Turbines: Monitoring shaft axial position to prevent thrust bearing failures.

-

Gas Turbines: Ensuring radial shaft positioning remains within operational tolerances.

-

Compressors: Detecting shaft displacement and mechanical deformation early.

-

Generators: Protecting against shaft misalignment and related vibration issues.

-

Pumps: Monitoring mechanical wear and ensuring reliable pump operation.

-

Industrial Motors: Supervising motor shaft behavior under variable load conditions.

-

Petrochemical Plants: Assuring continuous machinery operation in high-risk environments.

Compatible Models – Used with 3500/45-02-00 135145-01

-

Bently Nevada 3300 XL Proximity Probe System

-

Bently Nevada 330500 Velomitor Sensor

-

Bently Nevada 330100 Proximity Probe

-

Bently Nevada 3500/22M Transient Data Interface

-

Bently Nevada 3500/15 Power Supply Module

-

Bently Nevada 3500/20 Rack Interface Module

Installation Instructions – Bently Nevada 3500/45-02-00 135145-01

-

Preparation: Ensure the 3500 rack is powered down before inserting the module.

-

Slot Assignment: Install the 3500/45 Position Monitor in the designated slots within the rack, adjacent to the corresponding relay and interface modules.

-

Sensor Wiring: Connect the proximity probes or other sensors to the input terminals according to the wiring diagram provided in the manual.

-

Configuration: Configure the module channels via the 3500 Configuration Software. Set alarm setpoints, measurement ranges, and communication preferences.

-

Power-Up: Restore power to the rack and monitor the initialization sequence.

-

Validation: Verify that each channel is properly detecting sensor signals and responding to position changes appropriately.

-

Routine Maintenance: Periodically check module operation and sensor connections to maintain system integrity.

Recommended 6 Related Models (Same Series or Similar) – With Parameters

| Model | Description | Dimensions (mm) | Weight (kg) | Operating Voltage |

|---|---|---|---|---|

| 3500/42M 138708-01 | Proximitor/Seismic Monitor | 241.3 × 24.9 × 233.7 | 0.6 | +24 VDC |

| 3500/40M 176449-01 | Proximitor Monitor | 241.3 × 24.9 × 233.7 | 0.6 | +24 VDC |

| 3500/44M 138607-01 | TMR Relay Module | 241.3 × 24.9 × 233.7 | 0.65 | +24 VDC |

| 3500/25 149369-01 | Keyphasor Module | 241.3 × 24.9 × 233.7 | 0.55 | +24 VDC |

| 3500/33 149986-01 | TMR Vibration Monitor | 241.3 × 24.9 × 233.7 | 0.6 | +24 VDC |

| 3500/32M 149986-02 | TMR Digital Output Module | 241.3 × 24.9 × 233.7 | 0.6 | +24 VDC |

Recommended 8 Popular Bently Nevada Models – With Parameters

| Model | Description | Dimensions (mm) | Weight (kg) | Operating Voltage |

|---|---|---|---|---|

| 3500/05 125680-01 | System Rack | 266.7 × 482.6 × 266.7 | 8.2 | N/A (Rack Only) |

| 3500/15 106M1081-01 | Power Supply Module | 241.3 × 24.9 × 233.7 | 0.8 | 85-264 VAC |

| 3500/22M 138607-01 | Transient Data Interface | 241.3 × 24.9 × 233.7 | 0.6 | +24 VDC |

| 3300 XL 330104-00-12-10-02-00 | Proximity Probe | Probe: 71.1 × 12.7 | 0.2 | Powered by Monitor |

| 330730-040-00-00 | Accelerometer | 25 × 25 × 65 | 0.1 | 18-28 VDC |

| 330180-90-00 | Extension Cable for Proximity Probes | Various lengths | 0.2 | N/A |

| 3500/94M 149991-01 | VGA Display Module | 241.3 × 24.9 × 233.7 | 1.0 | +24 VDC |

| 1900/65A | General Purpose Monitoring System | 241.3 × 24.9 × 233.7 | 2.5 | 18-32 VDC |

FAQ – Bently Nevada 3500/45-02-00 135145-01

Q1: What type of sensors are compatible with the 3500/45-02-00 135145-01 Position Monitor?

A1: The 3500/45 module is compatible with proximity probes and other standard position sensors used in industrial machinery monitoring.

Q2: Can the module be installed in any slot within the 3500 rack?

A2: No, it must be installed in the specific slots allocated for monitoring modules, following Bently Nevada’s slot configuration guidelines.

Q3: Is it possible to set different alarm thresholds for each channel?

A3: Yes, each channel can have independent alarm setpoints configured through the 3500 Configuration Software.

Q4: How often should I perform maintenance checks on the 3500/45 Position Monitor?

A4: It is recommended to perform routine validation checks every 6 months or during scheduled maintenance intervals.

Q5: Does the 3500/45 support digital communication output?

A5: Communication is typically routed through the 3500/22M module and is compatible with standard data acquisition systems.

Q6: What happens if a channel detects an abnormal shaft position?

A6: The module triggers alarms and can initiate protective shutdown actions if configured to do so, depending on the severity of the detected deviation.

Bently Nevada 3500/45-02-00 135145-01 Monitor I/O Modules

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||