| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

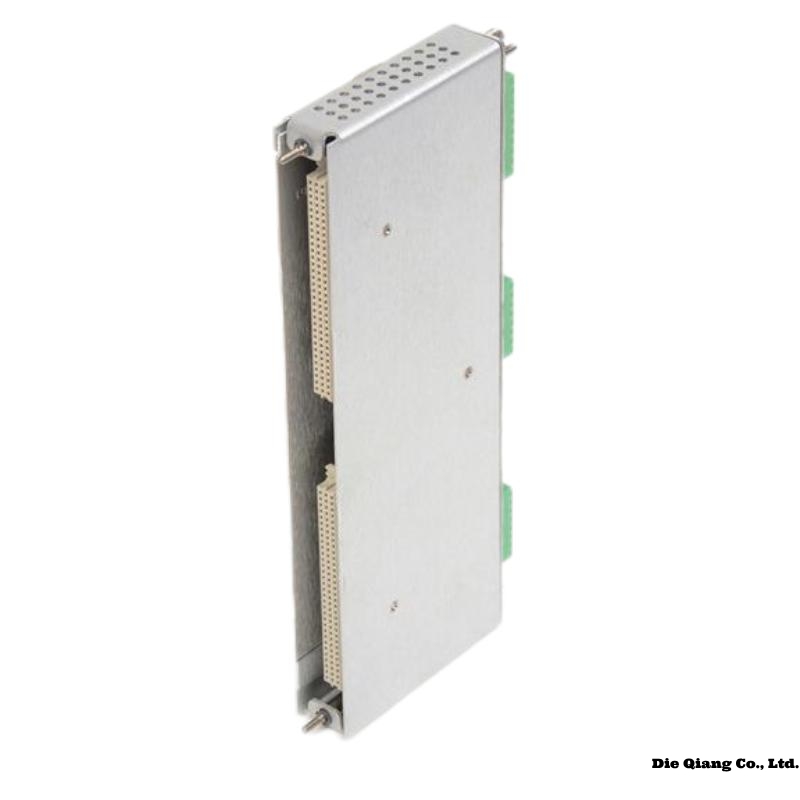

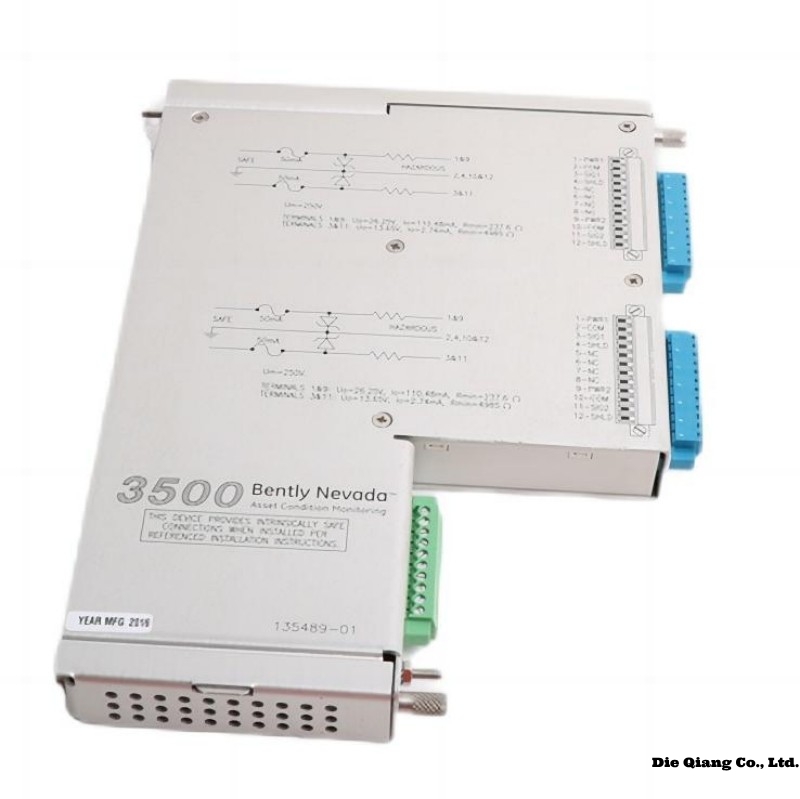

Bently Nevada 3500/42M-09-00 (Part No: 176449-02 + 140471-01)

Product Introduction

The Bently Nevada 3500/42M-09-00 is a high-performance Proximitor®/Seismic Monitor Module designed as part of the renowned Bently Nevada 3500 Series Machinery Protection System. This module is used to continuously monitor and protect critical rotating equipment such as turbines, compressors, motors, and pumps.

The 3500/42M-09-00 accepts input from proximity probes or seismic transducers and provides highly reliable real-time data for machine condition monitoring. This module integrates seamlessly into the 3500 Series rack, offering two channels of input processing, with independent alert and danger setpoints. It enhances machinery diagnostics by offering advanced signal conditioning and alarm logic, ensuring robust protection for industrial assets.

The component is configured using the 3500 Configuration Software and can interface with the 3500/20 Rack Interface Module for data output. It is a core module in many condition monitoring and predictive maintenance strategies for industrial machinery.

Product Advantages

-

Dual-channel Input: Offers two completely independent input channels for enhanced monitoring flexibility.

-

Versatile Sensor Compatibility: Works with a wide range of Bently Nevada proximity and seismic transducers.

-

High Accuracy & Reliability: Provides precise vibration and position data for early fault detection and machinery protection.

-

Advanced Alarm System: Supports independently configurable alert and danger levels for each channel.

-

Seamless Integration: Designed specifically for use within the 3500 Series rack system, ensuring easy integration and centralized monitoring.

-

Hot-swappable Module: Enables quick replacement without shutting down the system, minimizing downtime.

-

Field-configurable Settings: Easily configured using intuitive 3500 software, supporting flexible applications in different industries.

-

Comprehensive Diagnostics: Supports OK status checks, alarm checks, and fault diagnostics to ensure system reliability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Module Type | Proximitor®/Seismic Monitor Module |

| Model Number | 3500/42M-09-00 |

| Part Number | 176449-02 + 140471-01 |

| Input Channels | 2 Channels (independent) |

| Compatible Sensors | Proximity probes (e.g., 3300 XL), Seismic velocity/acceleration sensors |

| Output Type | Buffered output via front panel and rear terminal |

| Alarm Setpoints | Alert and Danger thresholds (individually programmable) |

| Configuration | Via 3500 Software |

| Power Supply | Supplied from the 3500 rack (nominal 18–32 VDC, typical 24 VDC) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 95% non-condensing |

| Mounting | 3500 Rack slot (requires adjacent I/O module) |

| Standards Compliance | CE, CSA, ATEX, and IECEx compliant |

Applications

-

Gas and Steam Turbines

-

Compressors

-

Motors and Generators

-

Centrifugal Pumps

-

Industrial Fans and Blowers

-

Gearboxes and Transmission Systems

-

Marine and Offshore Machinery Monitoring

-

Power Generation and Oil & Gas Facilities

Compatible and Supported Models

-

3500/20 – Rack Interface Module

-

3500/15 – Power Supply Module

-

3500/22M – Transient Data Interface Module

-

3500/94 – Display Interface Module

-

3300 XL Proximity Transducers

-

Velomitor Seismic Sensors

-

3500/32M – 4-Channel Relay Module

-

3500/92 – Communication Gateway

These models integrate with the 3500/42M module for full system protection and data transmission.

Installation Instructions

-

Rack Preparation: Ensure the 3500 rack is powered off and properly grounded before installing the module.

-

Slot Positioning: Insert the 3500/42M-09-00 into an available slot within the rack (requires adjacent terminal I/O module).

-

Wiring: Connect input signals from proximity or seismic transducers to the corresponding I/O module (140471-01). Secure wiring per installation manual.

-

Module Locking: Firmly seat the module until the latches click. Confirm module is aligned properly with the backplane.

-

Software Configuration: Use the 3500 Configuration Software to define channel type, alarm setpoints, OK limits, and scaling factors.

-

Power-On and Test: Restore power to the rack. Verify LED indicators, perform a self-test, and confirm sensor readings are accurate.

-

Data Integration: Connect the rack to communication systems (e.g., via 3500/92 or 3500/22M) for centralized monitoring.

Note: Always follow Bently Nevada’s official installation and safety guidelines to ensure compliance and safety.

6 Related or Same Series Models

| Model | Description | Channels | Main Use |

|---|---|---|---|

| 3500/40M | Proximitor® Monitor Module | 2 | Shaft vibration and position |

| 3500/44M | TSI (Turbine Supervisory Instrumentation) | 4 | Temperature, speed, expansion |

| 3500/25 | Keyphasor® Module | 2 | Phase and speed reference |

| 3500/32M | Relay Module | 4 | Alarm and shutdown relays |

| 3500/22M | Transient Data Interface | N/A | Data collection and logging |

| 3500/93 | LCD Display Module | N/A | Visual display of monitoring |

8 Popular Bently Nevada Models with Specs

| Model | Function | Channels | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| 3500/42M | Proximitor®/Seismic Monitor | 2 | 24 VDC | 241 × 24 × 240 | 0.9 |

| 3500/44M | TSI Module | 4 | 24 VDC | 241 × 24 × 240 | 0.9 |

| 3500/22M | Transient Data Interface | N/A | 24 VDC | 241 × 24 × 240 | 0.95 |

| 3500/25 | Keyphasor® Module | 2 | 24 VDC | 241 × 24 × 240 | 0.85 |

| 3500/15 | Power Supply Module | N/A | 85–264 VAC | 241 × 24 × 240 | 1.0 |

| 3500/20 | Rack Interface Module | N/A | 24 VDC | 241 × 24 × 240 | 0.9 |

| 3500/32M | Relay Module | 4 Relays | 24 VDC | 241 × 24 × 240 | 0.9 |

| 3500/93 | LCD Display Module | N/A | 24 VDC | 241 × 76 × 240 | 1.2 |

FAQ – Frequently Asked Questions

Q1: What is the difference between the 3500/42M and 3500/40M modules?

A1: The 3500/42M supports both proximity and seismic sensors, whereas the 3500/40M is primarily for proximity transducers only.

<br>

Q2: Can I use the 3500/42M with third-party sensors?

A2: Bently Nevada strongly recommends using their certified sensors for guaranteed compatibility and system accuracy.

<br>

Q3: How are alert and danger alarms configured?

A3: Alarms are configured using the 3500 Configuration Software, allowing precise setting of threshold levels for each channel.

<br>

Q4: Does this module support redundant channel operation?

A4: No, the 3500/42M is designed for independent channel operation; for redundancy, consider system-level design approaches.

<br>

Q5: What is the lifespan of the module?

A5: Under standard operating conditions, Bently Nevada modules typically last over 10 years with routine maintenance.

<br>

Q6: Is hot-swapping supported for the 3500/42M?

A6: Yes, the module can be replaced without shutting down the rack if performed according to Bently Nevada procedures.

Bently Nevada 3500/42M-09-00 Preamplifier Seismic Monitor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

176449-02+140471-01, 3500/42M-09-00, Bently Nevada, Bently Nevada 3500/42M-09-00 176449-02+140471-01, Preamplifier Seismic Monitor