| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

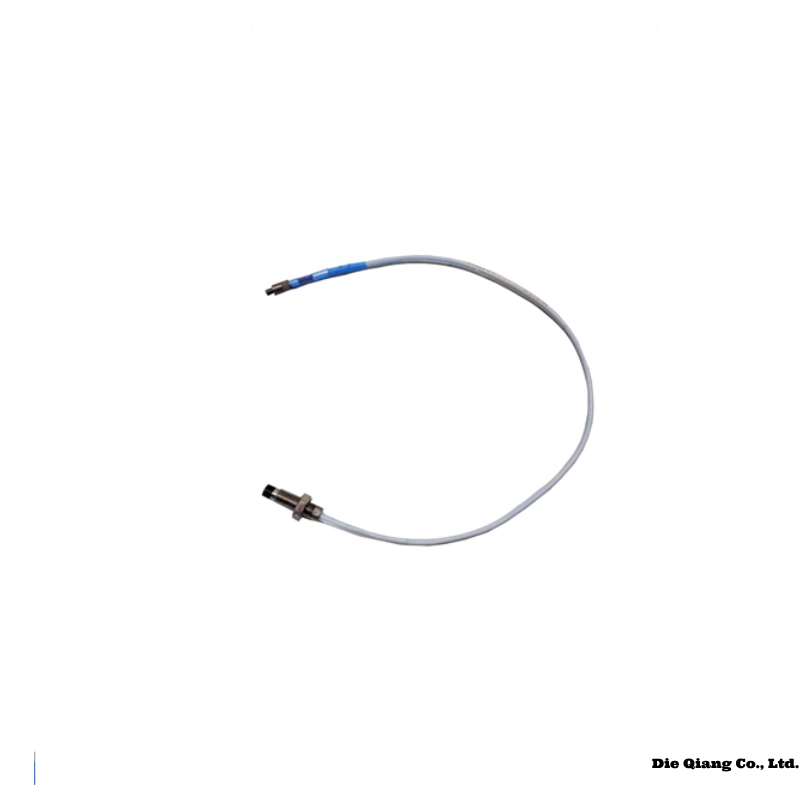

Bently Nevada 330904-02-14-05-02-05 Vibration Sensor

Product Introduction

The Bently Nevada 330904-02-14-05-02-05 is an advanced industrial accelerometer developed by Bently Nevada, a globally recognized leader in condition monitoring and asset protection solutions. Designed for precision vibration monitoring, this model is part of the 330900 series and provides accurate, real-time feedback for rotating machinery, enabling early fault detection and predictive maintenance. It is engineered for harsh industrial environments, including power plants, refineries, and manufacturing facilities.

The sensor converts mechanical vibration into a corresponding electrical signal and is typically used in conjunction with Bently Nevada’s 3500 monitoring systems. With its robust stainless-steel housing and hermetically sealed construction, this sensor ensures long-term stability and reliability even under extreme temperature, humidity, and vibration conditions.

Product Advantages

-

High Sensitivity: Provides precise vibration measurement, enhancing predictive maintenance capabilities.

-

Rugged Design: Constructed with stainless steel and hermetic sealing, ideal for harsh industrial environments.

-

Wide Frequency Range: Capable of detecting a broad spectrum of vibration signatures for accurate condition diagnosis.

-

Compatibility: Seamlessly integrates with Bently Nevada 3500 series monitoring systems and other standard interfaces.

-

Reduced Downtime: Enables early detection of mechanical faults, preventing catastrophic equipment failure and minimizing unplanned outages.

-

Maintenance-Free Operation: Long-term stability reduces the need for recalibration or replacement.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330904-02-14-05-02-05 |

| Type | Industrial Accelerometer |

| Sensitivity | 100 mV/g ±10% |

| Frequency Range | 0.5 Hz to 10,000 Hz |

| Measurement Range | ±50 g peak |

| Output Impedance | <100 ohms |

| Power Supply Voltage | 18–30 VDC (nominal 24 VDC) |

| Output Signal | Voltage (analog signal) |

| Connector Type | MIL-C-5015 2-pin |

| Mounting Type | Stud mounted (1/4-28 UNF) |

| Housing Material | Stainless Steel |

| Sealing | Hermetically sealed |

| Operating Temperature | -54°C to +121°C (-65°F to +250°F) |

| Shock Limit | 5,000 g peak |

| Cable length | 5 m |

| Weight | 0.255kg |

| Certification | CE, RoHS, ATEX options available |

Product Applications

The Bently Nevada 330904-02-14-05-02-05 accelerometer is widely used in various industrial sectors, including:

-

Power Generation: Turbine and generator vibration monitoring

-

Oil and Gas: Compressors, pumps, and drilling machinery monitoring

-

Petrochemical and Refining: Equipment health monitoring in harsh, explosive environments

-

Steel and Cement Plants: Gearboxes and roller bearings condition tracking

-

Pulp and Paper Industry: High-speed rotating equipment analysis

-

Water Treatment Facilities: Monitoring of motor-driven mechanical assets

Compatible Models

This sensor is compatible with the following Bently Nevada components and systems:

-

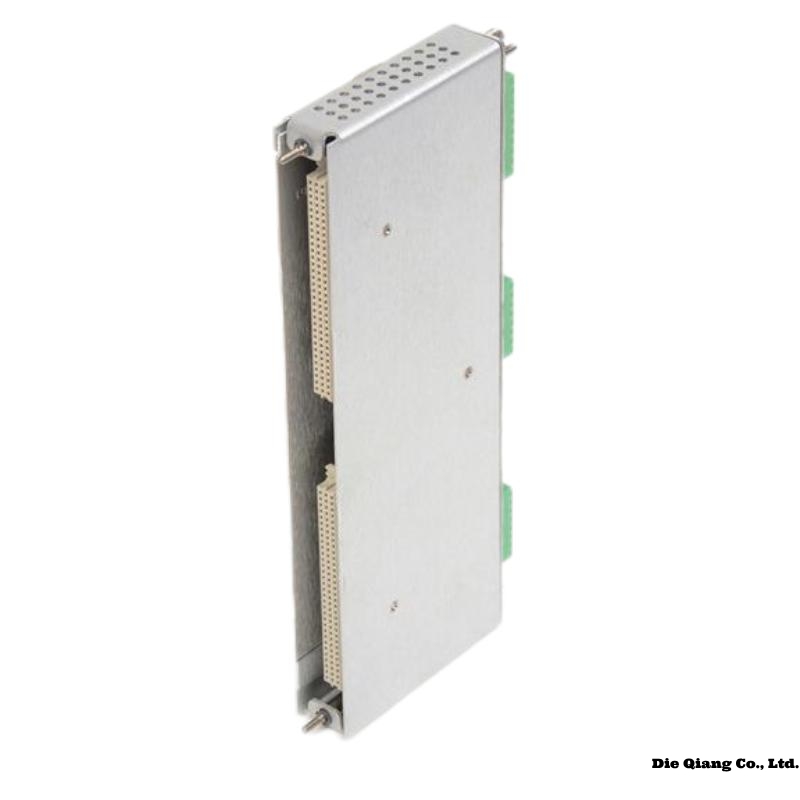

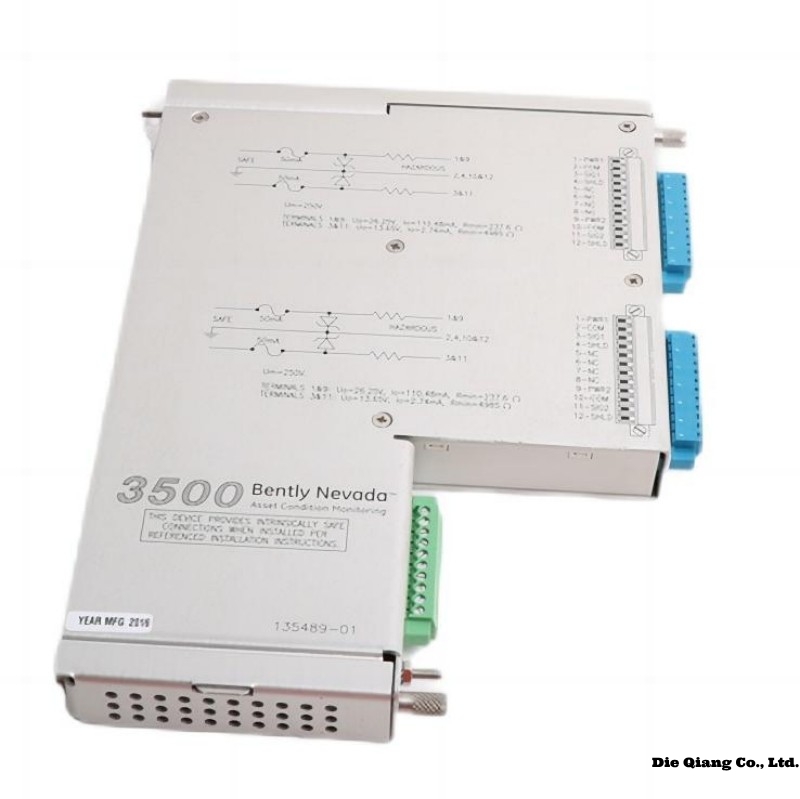

3500/42M Proximitor Seismic Monitor

-

3500/15 Power Supply Module

-

3500/22M Transient Data Interface

-

330180 Extension Cable

-

330130 Connector Housing

-

330101/330103 Proximity Probes (for combined systems)

Installation Instructions

-

Mounting Surface: Ensure the surface is clean, flat, and free of oil. A flatness of ±0.001 in is recommended.

-

Mounting Stud: Use a 1/4-28 UNF stud torque tightened to 5.4 N·m (48 in-lbs) to secure the sensor.

-

Orientation: Align the sensor in the desired measurement axis direction. Horizontal and vertical installations are supported.

-

Wiring: Connect the MIL-C-5015 connector to the extension cable, ensuring a tight and secure seal.

-

Cable Routing: Avoid sharp bends, excessive lengths, or EMI-rich paths.

-

System Calibration: After installation, calibrate using a signal conditioner or monitoring system compatible with the sensor output (e.g., Bently 3500).

-

Environmental Checks: Verify sealing and insulation integrity in moisture-prone or ATEX-rated environments.

6 Related Models in the Same Series

| Model | Sensitivity | Frequency Range | Output | Mounting | Weight |

|---|---|---|---|---|---|

| 330904-02-12-05-02-05 | 100 mV/g | 0.5 Hz – 10 kHz | Voltage | Stud | 85 g |

| 330904-02-13-10-02-05 | 100 mV/g | 0.5 Hz – 10 kHz | Voltage | Adhesive | 90 g |

| 330900-02-14-05-02-00 | 100 mV/g | 1 Hz – 9 kHz | Voltage | Stud | 83 g |

| 330901-00-20-10-02-00 | 500 mV/g | 10 Hz – 5 kHz | Voltage | Stud | 100 g |

| 330930-065-01-00 | Dual Output | 0.5 Hz – 10 kHz | Velocity/Accel | Flanged | 150 g |

| 330980-71-00 | 100 mV/g | 2 Hz – 10 kHz | Voltage | Magnetic | 95 g |

8 Popular Bently Nevada Models

| Model | Type | Description | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| 330104-00-07-10-02-00 | Proximity Probe | 8 mm Tip, 10 ft Cable | N/A | 8 mm diameter | 120 g |

| 3500/42M | Vibration Monitor Module | 4-channel monitor for sensors | 24 VDC | 120 x 30 x 150 | 300 g |

| 3500/15 | Power Supply Module | Universal AC/DC input module | 85-264 VAC | 115 x 25 x 130 | 250 g |

| 330180-91-05 | Extension Cable | 5-meter armored cable for sensors | N/A | Cable | 500 g |

| 330130-040-00-00 | Connector Housing | 4.0-meter cable, coaxial configuration | N/A | Cable | 400 g |

| 330106-05-30-10-02-00 | Proximity Probe | 5mm probe for tight space monitoring | N/A | 5 mm diameter | 100 g |

| 330103-00-05-10-02-00 | Proximity Probe | 8mm reverse mount probe | N/A | 8 mm diameter | 110 g |

| 330500-02-00 | Velocity Sensor | Seismic velocity sensor | 24 VDC | 80 x 20 x 50 | 130 g |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the 330904-02-14-05-02-05 sensor?

A1: Its primary function is to convert mechanical vibration into an electrical signal for monitoring and diagnostic analysis in rotating machinery.

Q2: Is the sensor compatible with non-Bently monitoring systems?

A2: Yes, the sensor provides an industry-standard voltage output and can work with compatible third-party data acquisition systems, though performance is optimized with Bently Nevada’s 3500 series.

Q3: Can the sensor be installed in high-temperature environments?

A3: Yes, it supports operating temperatures from -54°C to +121°C, making it suitable for harsh industrial applications.

Q4: What is the recommended cable length for installation?

A4: The sensor supports extension cables typically up to 300 feet (91 meters) with minimal signal loss using Bently Nevada coaxial cables.

Q5: Does the sensor require periodic recalibration?

A5: While the sensor is designed for long-term stability, periodic verification during plant maintenance intervals is recommended to ensure data integrity.

Q6: How should the sensor be mounted for optimal performance?

A6: The sensor should be mounted securely using a 1/4-28 UNF stud on a clean, flat surface. Ensure proper alignment in the direction of interest to capture accurate vibration data.

Bently Nevada 330904-02-14-05-02-05 Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||