| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

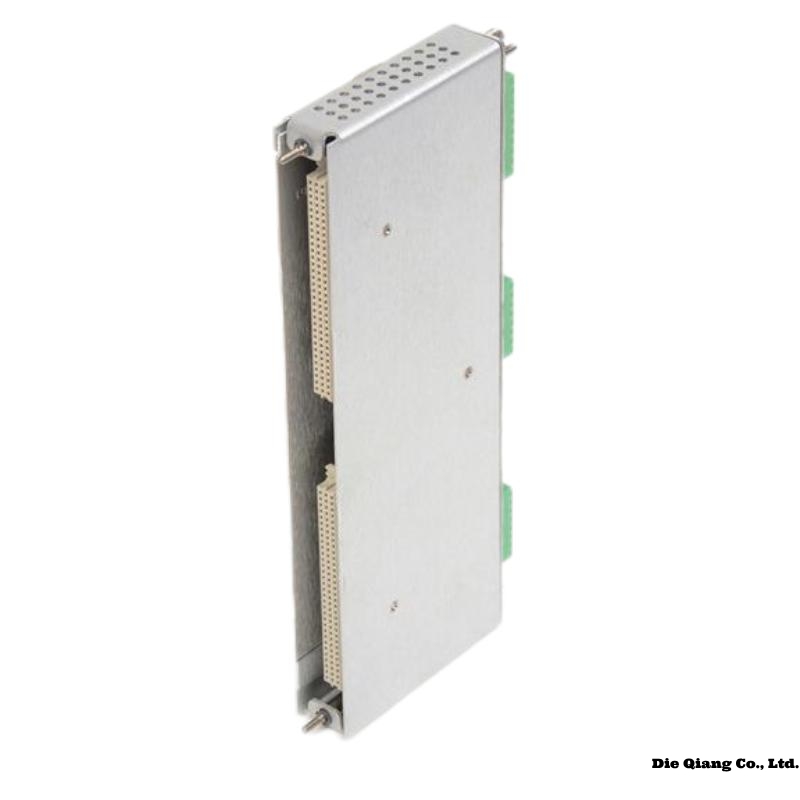

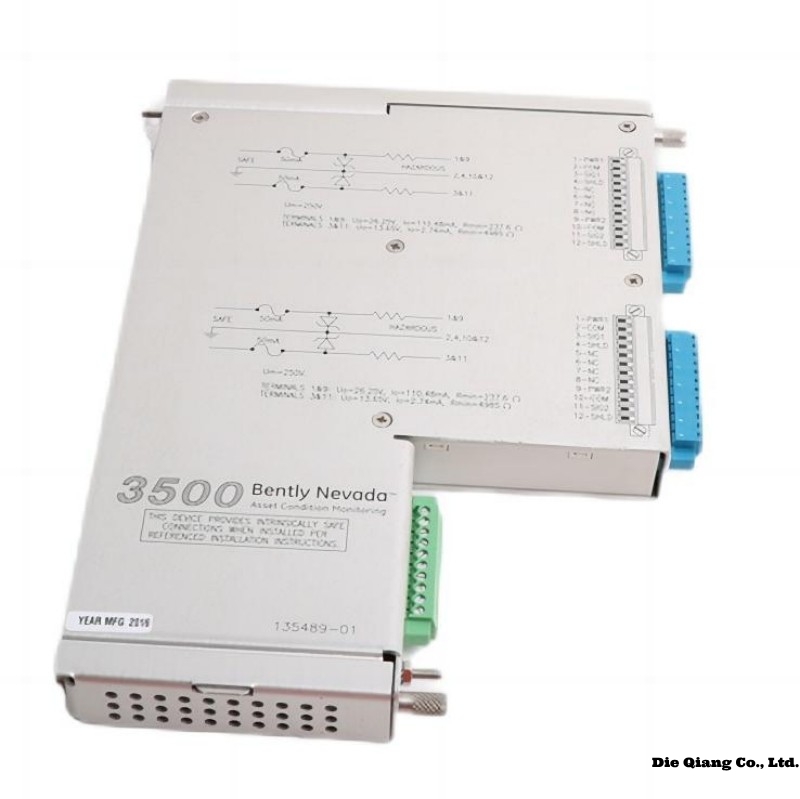

Bently Nevada 330904-02-10-70-01-00 Proximity Probe System

Product Introduction

The Bently Nevada 330904-02-10-70-01-00 is part of the trusted 3300 XL series of proximity probe systems developed by Bently Nevada, a global leader in condition monitoring and protection systems. Designed for critical machinery monitoring applications, this probe system delivers precise, non-contact vibration and position measurements. It is typically used for shaft vibration, radial position, thrust position, and eccentricity measurements in various rotating machinery.

The 330904-02-10-70-01-00 features a high-quality probe and cable assembly that are engineered for robust industrial environments, providing reliability in extreme conditions such as high temperature, high humidity, and chemically aggressive environments. The system is compatible with a wide range of Bently Nevada drivers and monitors, enhancing its versatility across industrial sectors.

This probe system is typically implemented in turbines, compressors, motors, pumps, and gearboxes to provide real-time data for predictive maintenance and machine protection systems.

Product Advantages

-

High Reliability in Harsh Conditions: Designed to withstand extreme temperature variations, high pressure, and harsh chemicals, making it suitable for heavy industrial use.

-

Accurate Non-Contact Measurement: Offers precise shaft vibration and position detection, ensuring accurate diagnostics and machinery protection.

-

Robust Construction: Rugged stainless-steel body construction enhances mechanical durability and longevity.

-

Extended Probe Length Options: Flexible configurations available with various cable and probe lengths to match application needs.

-

Easy Integration: Seamless compatibility with Bently Nevada monitors and driver systems, such as the 3300 XL series and 3500 Monitoring Systems.

-

Proven Reliability: Trusted by industries worldwide for over a decade with a proven track record in vibration and position monitoring systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330904-02-10-70-01-00 |

| Probe Type | Proximity Probe (3300 XL Series) |

| Sensing Technology | Eddy Current |

| Measurement Range | 80 mils (2 mm) |

| Linear Range | 0.5 mm to 2.0 mm |

| Sensitivity | 7.87 mV/µm (200 mV/mil) ±5% |

| Material | Stainless Steel |

| Mounting Thread | M10 x 1.0 |

| Connector Type | Miniature coaxial connector |

| Operating Temperature | -35°C to +177°C (-31°F to +351°F) |

| Weight | 0.255kg |

| Voltage Supply | -24 VDC (via driver or monitor system) |

| Compliance | CE, RoHS, ATEX, IECEx (depending on configuration) |

| Enclosure Rating | IP67 (when properly installed) |

| Cable length | 7 m |

Product Applications

-

Steam and Gas Turbines – Shaft vibration and thrust position monitoring

-

Compressors – Detect rotor imbalance and bearing wear

-

Industrial Pumps – Identify cavitation and misalignment

-

Motors and Generators – Shaft alignment and eccentricity monitoring

-

Gearboxes – Vibration analysis and condition-based maintenance

-

Fans and Blowers – Vibration diagnostics for rotating equipment

Compatible Models

The 330904-02-10-70-01-00 is designed to be used with the following Bently Nevada components:

-

3300 XL Proximitor Sensor (e.g., 330180 Series)

-

3300 XL Extension Cable (e.g., 330130-040-00-00)

-

3500 Series Monitoring Systems

-

3300 Series Monitors

-

RK 4-15 Extension Probes

-

TK 3-2 Calibration Kit

These components collectively form a complete eddy current proximity transducer system used for precise machinery monitoring.

Installation Instructions

-

Preparation

Ensure the probe mounting surface is clean and free from debris or oil. Check compatibility of the extension cable and proximitor sensor with the probe model. -

Mounting the Probe

Thread the proximity probe into the mounting hole using the M10 x 1.0 thread. Use a torque wrench to tighten the probe to the recommended torque value of 1.5 to 2.0 Nm. -

Gap Adjustment

Set the initial gap between the probe tip and the shaft surface using a feeler gauge. This ensures the sensor operates within its linear range. -

Connect Extension Cable

Attach the coaxial cable to the probe’s miniature connector and secure it using the locking mechanism. -

Connect to Proximitor

Plug the extension cable into the corresponding proximitor sensor. Confirm connections are secure and correctly routed. -

Calibration

Perform a system calibration using a calibration kit (e.g., TK 3-2) to ensure accurate displacement measurements. -

Final Check

Once installed, verify probe readings via the monitoring system. Check for proper signal levels and baseline vibration data.

Related Bently Nevada Models (Same Series or Similar Use)

| Model Number | Description | Probe Tip Diameter | Cable Length | Operating Temp. | Application Area |

|---|---|---|---|---|---|

| 330904-02-12-10-02-00 | Proximity probe, longer cable | 5 mm | 12 ft | -35°C to +177°C | General machinery monitoring |

| 330104-00-05-10-02-00 | Shorter probe, standard cable | 8 mm | 5 ft | -35°C to +121°C | Tight spaces, pumps |

| 330130-040-00-00 | Extension cable for 3300 XL system | N/A | 4 m | -40°C to +177°C | Probe extension |

| 330180-50-CN | Proximitor sensor for 3300 XL series | N/A | N/A | -35°C to +85°C | Signal processing |

| 330106-05-30-10-02-00 | Probe system with enhanced length | 5 mm | 30 ft | -35°C to +177°C | Remote mounting |

| 330173-00-04-10-02-00 | Narrow body probe for limited space | 5 mm | 4 ft | -35°C to +177°C | Compressors, turbines |

Popular Bently Nevada Models and Specifications

| Model Number | Description | Voltage Supply | Dimensions (mm) | Weight (g) | Operating Temp. | Application |

|---|---|---|---|---|---|---|

| 330104-00-05-10-02-00 | Proximity probe with 5 ft cable | -24 VDC | 50 x 8 | 160 | -35°C to +121°C | Pumps, turbines |

| 330130-040-00-00 | Extension cable, 4 m | N/A | N/A | 120 | -40°C to +177°C | Probe signal extension |

| 330180-91-05 | Proximitor sensor | -24 VDC | 90 x 20 x 15 | 250 | -35°C to +85°C | Works with proximity probes |

| 3500/42M-01-00 | Vibration monitor for proximity transducers | 24 VDC | 130 x 30 x 120 | 450 | -40°C to +70°C | Vibration monitoring (4-channel) |

| 3500/22M-01-01-00 | Transient Data Interface (TDI) module | 24 VDC | 130 x 30 x 120 | 470 | -40°C to +70°C | System integration |

| 330500-02-00 | High-temperature proximity probe | -24 VDC | 60 x 8 | 190 | -50°C to +230°C | Gas turbines |

| 330103-00-07-10-02-00 | Standard proximity probe | -24 VDC | 70 x 8 | 170 | -35°C to +177°C | General machinery |

| 330105-02-12-10-02-00 | Long-range probe with 12 ft cable | -24 VDC | 80 x 8 | 200 | -35°C to +177°C | Heavy equipment |

FAQs (Frequently Asked Questions)

Q1: What is the primary function of the 330904-02-10-70-01-00 probe?

A1: It is designed to measure the vibration and position of rotating shafts in machinery using eddy current technology.

Q2: Can this proximity probe be used in high-temperature environments?

A2: Yes, it supports continuous operation in temperatures up to 177°C, making it suitable for harsh industrial environments.

Q3: What monitoring systems are compatible with this probe?

A3: It is fully compatible with the 3300 XL Proximitor Sensors and 3500 Series Monitoring Systems.

Q4: Does this model support reverse mounting or side-view configurations?

A4: Yes, when mounted correctly and calibrated, the probe supports various mounting orientations, including reverse views.

Q5: How often should the system be calibrated after installation?

A5: Calibration should be performed during initial installation and then annually or during scheduled maintenance cycles.

Q6: What is the standard cable length and can it be customized?

A6: This model comes with a 10 ft (3 m) cable, but longer or shorter lengths are available upon request to fit different installation needs.

Bently Nevada 330904-02-10-70-01-00 Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||