| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

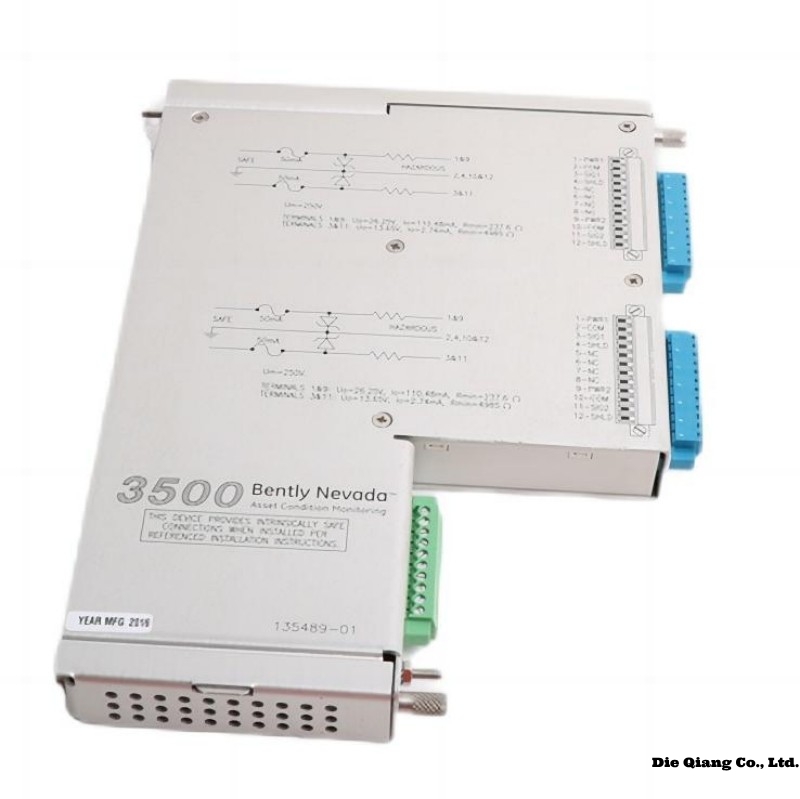

Bently Nevada 330705-02-18-10-02-05 Product Overview

The Bently Nevada 330705-02-18-10-02-05 is a highly reliable Proximity Sensor designed to offer continuous monitoring of machine shaft position and vibration. Developed for demanding industrial environments, this proximity probe ensures precise measurements even in high-temperature and high-vibration areas. As part of the renowned 3300 XL series, it incorporates advanced Eddy Current technology to provide accurate, stable, and repeatable outputs over long periods, minimizing maintenance and system downtime.

The 330705-02-18-10-02-05 model is specifically engineered for applications where robust, durable, and highly sensitive vibration monitoring is critical to operational safety and efficiency. It is a key component in the Bently Nevada condition monitoring and protection systems, widely used across multiple industries including power generation, petrochemical, and heavy manufacturing.

Advantages of the Bently Nevada 330705-02-18-10-02-05

-

Exceptional Measurement Accuracy: Utilizes eddy current principles to ensure non-contact, high-precision vibration and position monitoring.

-

Industrial Durability: Built to withstand harsh environments, including exposure to oil, dirt, extreme temperatures, and mechanical shocks.

-

Extended Operational Life: Designed for continuous operation over long periods without significant drift or need for recalibration.

-

High-Temperature Tolerance: Suitable for operations in environments with high ambient temperatures.

-

Seamless System Integration: Fully compatible with Bently Nevada 3300 XL monitoring systems, ensuring easy installation and integration.

-

Compact and Rugged Design: Facilitates installations in confined spaces while offering excellent resistance to mechanical stresses.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 330705-02-18-10-02-05 |

| Probe Type | Proximity Probe |

| Measurement Range | 0 to 2 mm (0 to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Linear Range | 0.25 mm to 2.0 mm (10 to 80 mils) |

| Probe Tip Diameter | 8 mm (0.31 inch) |

| Thread Size | 3/8-24 UNF |

| Voltage Requirement | -24 VDC to -28 VDC (supplied by driver) |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Weight | 0.07kg |

| Housing Material | Stainless Steel |

| Compliance | RoHS compliant, CE Marked |

| Application Type | Industrial Machinery Monitoring |

| Installation Environment | Indoor and Outdoor |

| Response Time | ≤1 ms |

| Certifications | ATEX, IECEx (optional versions) |

| Cable length | 1 m |

Applications of the 330705-02-18-10-02-05

-

Turbine Monitoring: Used extensively in gas and steam turbines for shaft position and vibration measurements.

-

Compressor Protection: Protects large compressors by early detection of mechanical faults.

-

Pump Monitoring: Ensures operational integrity of critical process pumps.

-

Motor and Generator Monitoring: Monitors shaft movement and prevents failures.

-

Gearbox Monitoring: Detects misalignments and bearing failures in gearboxes.

-

Heavy Machinery in Mining and Steel Plants: Ideal for monitoring critical rotating equipment.

Compatible Models for Use

The 330705-02-18-10-02-05 proximity probe is compatible with:

-

Bently Nevada 3300 XL 8 mm Drivers

-

Bently Nevada 3300 XL Monitors

-

3500/22M Transient Data Interface

-

3500/40M Proximitor Monitors

-

3300/16-XX Six-Channel Monitors

-

330400 and 330425 Extension Cable Series

Installation Instructions

-

Preparation: Verify that the installation environment is free from excessive dust and oil before installing the probe.

-

Mounting: Thread the probe into the mounting location using the 3/8-24 UNF thread. Tighten using a torque wrench to 0.5–0.7 Nm (5–6 in-lbs).

-

Positioning: Adjust the probe tip gap to the recommended initial gap (1 mm ±0.2 mm) using a feeler gauge.

-

Routing Cables: Secure the cable properly to prevent vibration-induced damage. Avoid sharp bends and protect the cable from abrasive surfaces.

-

Connection: Connect the probe to the extension cable and then to the proximitor driver. Ensure tight and clean connections.

-

Testing: After installation, verify the output signal using a test signal generator and confirm correct functionality.

-

Documentation: Record installation details, cable lengths, and serial numbers for future maintenance tracking.

Related Models (Same Series / Closely Related)

| Model | Description | Sensitivity | Cable Length | Temperature Range |

|---|---|---|---|---|

| 330705-02-12-10-02-05 | Proximity Probe, 12 ft cable | 200 mV/mil | 12 feet | -35°C to +177°C |

| 330705-02-15-10-02-05 | Proximity Probe, 15 ft cable | 200 mV/mil | 15 feet | -35°C to +177°C |

| 330705-02-20-10-02-05 | Proximity Probe, 20 ft cable | 200 mV/mil | 20 feet | -35°C to +177°C |

| 330750-02-18-10-02-05 | High Temp Proximity Probe | 200 mV/mil | 18 feet | Up to +450°F (+232°C) |

| 330780-91-05 | Dual Vibration & Thrust Position | 7.87 mV/μm | 5 meters | -51°C to +177°C |

| 330850-50-05 | Reverse Mount Probe | 7.87 mV/μm | 5 meters | -35°C to +177°C |

Popular Bently Nevada Models

| Model | Description | Measurement Type | Voltage | Weight | Dimensions |

|---|---|---|---|---|---|

| 3500/22M | Transient Data Interface Module | System Communication | 24 VDC | 0.5 kg | 120 × 25 × 200 mm |

| 3500/40M | Proximitor Monitor | Shaft Vibration Monitoring | 24 VDC | 0.45 kg | 120 × 25 × 200 mm |

| 330104-00-09-10-02-00 | Proximity Probe, 5mm | Displacement Measurement | Supplied via driver | 0.14 kg | Cable Length 9m, Tip Ø5mm |

| 330130-040-00-00 | Extension Cable for 3300 Series | Cable Assembly | N/A | 0.2 kg | 5 m cable length |

| 330180-51-00 | Proximitor Sensor | Vibration & Position | -24 VDC | 0.3 kg | 120 × 25 × 200 mm |

| 330500-02-00 | Velocity Sensor | Machine Velocity Monitoring | 18-30 VDC | 0.5 kg | 100 × 40 × 60 mm |

| 190501-00 | Acceleration Sensor | Acceleration Monitoring | 18-28 VDC | 0.2 kg | 38 mm diameter |

| 165855-01 | Keyphasor Module | Rotational Speed Monitoring | 24 VDC | 0.45 kg | 120 × 25 × 200 mm |

Frequently Asked Questions (FAQ)

Q1: What is the primary use of the Bently Nevada 330705-02-18-10-02-05?

A1:

It is primarily used for shaft vibration and position monitoring in industrial rotating machinery to ensure equipment protection and reliability.

Q2: Can this probe operate in high-temperature environments?

A2:

Yes, the 330705-02-18-10-02-05 is rated for operation up to +177°C (+350°F), making it suitable for high-temperature industrial applications.

Q3: What monitoring systems is this probe compatible with?

A3:

It is fully compatible with Bently Nevada 3300 XL systems, including 3500/40M Proximitor Monitors and 3500/22M Transient Data Interface modules.

Q4: How do I verify proper installation after mounting the probe?

A4:

You should measure the probe’s DC output at the initial gap setting and verify it matches expected calibration values. Signal stability and linearity must also be confirmed.

Q5: Is the 330705-02-18-10-02-05 probe ATEX certified for hazardous areas?

A5:

Yes, ATEX and IECEx-certified versions are available for installations requiring hazardous area compliance.

Q6: How often should the probe be recalibrated?

A6:

Under normal conditions, recalibration is not required frequently. However, it is recommended to inspect and verify calibration during major machinery overhauls or if signal drift is observed.

Bently Nevada 330705-02-18-10-02-05 3300 XL 11 mm Reverse Mount Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 11 mm Reverse Mount Probe, 330705-02-18-10-02-05, Bently Nevada, Bently Nevada 330705-02-18-10-02-05