| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

📘 Product Introduction

The Bently Nevada 330703-000-060-10-02-00 is a high-performance Velomitor Piezo-velocity Sensor designed specifically for machinery vibration monitoring. Engineered to deliver accurate velocity measurements in rugged industrial environments, this sensor integrates a piezoelectric sensing element with a velocity output signal, providing superior performance in demanding applications.

As part of the renowned Bently Nevada 330700 Series, this sensor is widely adopted in turbine monitoring, rotating equipment diagnostics, and predictive maintenance programs. The sensor offers high sensitivity, excellent frequency response, and durable construction to ensure consistent performance over long periods.

Ideal for continuous vibration monitoring systems, the 330703 sensor is optimized to interface with Bently Nevada’s Proximitor® monitoring units and machinery protection systems.

⭐ Product Advantages

-

Robust Design: Rugged stainless steel construction allows for reliable operation in harsh industrial environments.

-

High Sensitivity: Provides precise velocity measurements using piezoelectric technology.

-

Wide Frequency Response: Enables accurate monitoring over a broad spectrum of vibration frequencies.

-

Easy Integration: Seamlessly integrates with Bently Nevada monitoring and protection systems.

-

Hermetically Sealed: Offers protection against moisture and contaminants for longer service life.

-

Low Noise Performance: Ensures signal integrity even in noisy environments.

📊 Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330703-000-060-10-02-00 |

| Sensing Element | Piezoelectric |

| Measurement Output | Velocity (RMS) |

| Frequency Range | 4.5 Hz to 5 kHz (±3 dB) |

| Sensitivity | 3.94 mV/mm/s (100 mV/in/s) ±10% @ 80 Hz |

| Output Impedance | <100 ohms |

| Power Supply Requirement | +22 Vdc to +30 Vdc (standard is 24 Vdc) |

| Mounting Thread | 1/4-28 UNF-2A |

| Case Material | Stainless Steel |

| Connector Type | 2-pin MIL-C-5015 |

| Cable Length | 6.0 meters (customizable) |

| Operating Temperature | −54°C to +121°C (−65°F to +250°F) |

| Weight | 0.255kg |

| Cable length | 1m |

| Voltage Range | 24 Vdc nominal |

| Certification | CE, CSA, ATEX (when applicable) |

🛠 Applications

The 330703-000-060-10-02-00 is commonly used in:

-

Gas and steam turbines

-

Compressors

-

Industrial fans and blowers

-

Motors and pumps

-

Gearboxes

-

Paper machines and rolling mills

-

Condition monitoring systems

-

Vibration analysis for predictive maintenance

🔗 Compatible and Supporting Models

This sensor is fully compatible with the following systems and models:

-

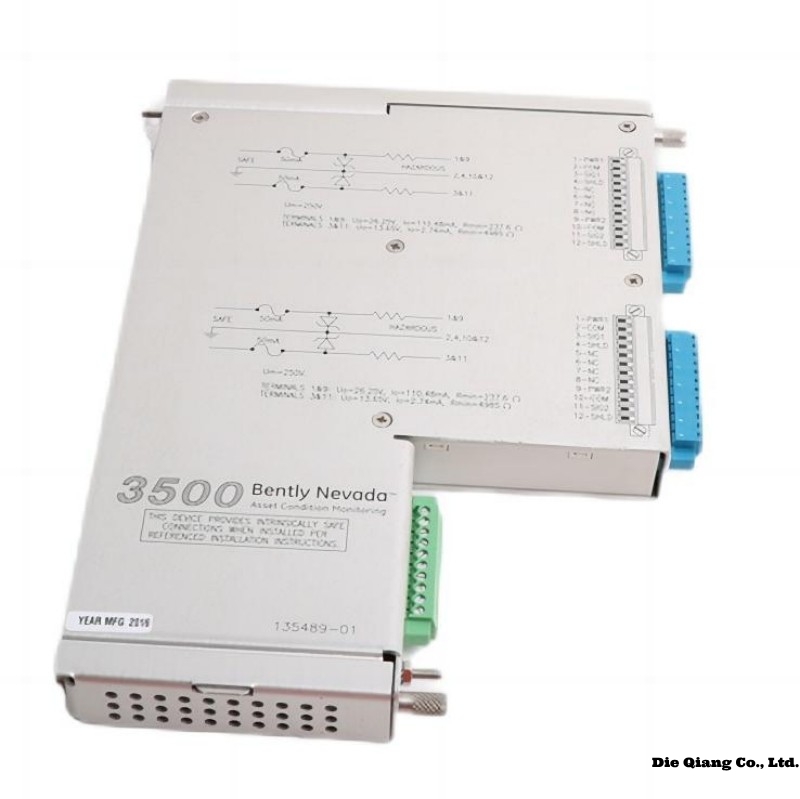

Bently Nevada 3500 Monitoring System

-

Proximitor® Seismic Monitoring Units

-

BN 3300 Series Racks

-

BN 330104/106 Extension Cables

-

BN 330180 Connector Adapters

-

BN 330400 Accelerometers (for hybrid monitoring systems)

🔧 Installation Instructions

-

Mounting Surface Preparation: Ensure the mounting surface is clean, flat, and free of paint or debris.

-

Thread Engagement: Install the sensor using the 1/4-28 UNF-2A threaded mount. Use thread-locking compound if necessary.

-

Torque Specification: Tighten to 2.0–2.5 Nm (18–22 in-lb) using a calibrated torque wrench.

-

Cable Connection: Connect the 2-pin MIL-C-5015 connector securely. Route the cable to avoid sharp bends and electromagnetic interference.

-

Power Supply: Connect to a +24 Vdc power source compatible with Bently Nevada monitoring systems.

-

Verification: After installation, verify output using a signal analyzer or monitoring system for signal accuracy.

-

Environmental Sealing: If used outdoors, apply weatherproofing materials around the sensor and connector.

🔁 Six Related Models

| Model Number | Cable Length | Sensitivity (mV/in/s) | Frequency Range | Mounting Thread | Weight |

|---|---|---|---|---|---|

| 330703-000-120-10-02-00 | 12 m | 100 | 4.5 Hz to 5 kHz | 1/4-28 UNF | 135 g |

| 330703-000-030-10-02-00 | 3 m | 100 | 4.5 Hz to 5 kHz | 1/4-28 UNF | 128 g |

| 330730-040-00-00 | 4 m | 100 | 4.5 Hz to 5 kHz | Stud mount | 120 g |

| 330752-050-00-00 | 5 m | 100 | 2 Hz to 7 kHz | Adhesive mount | 122 g |

| 330704-000-060-10-02-00 | 6 m | 100 | 2 Hz to 10 kHz | 1/4-28 UNF | 135 g |

| 330900-00-10-10-02-00 | 10 m | 100 | 3 Hz to 6 kHz | 1/4-28 UNF | 140 g |

🌟 Eight Popular Bently Nevada Models

| Model Number | Product Type | Application | Frequency Range | Weight | Dimensions (mm) | Voltage |

|---|---|---|---|---|---|---|

| 330104-00-05-10-02-00 | Proximity Probe | Shaft Vibration Monitoring | DC – 10 kHz | 90 g | 70 × 8 | 24 Vdc |

| 330106-05-30-10-02-00 | Extension Cable | Vibration Signal Extension | N/A | 150 g | 3000 mm length | N/A |

| 330130-040-00-00 | Accelerometer | General Vibration | 2 Hz to 10 kHz | 125 g | 60 × 24 | 24 Vdc |

| 3500/42M | Dynamic Vibration Monitor | Rotating Machinery | 4 Hz to 10 kHz | 650 g | 110 × 25 × 250 | 18–30 V |

| 330180-50-CN | Connector Assembly | Probe/Cable Connection | N/A | 75 g | N/A | N/A |

| 330400 | Accelerometer | Seismic Monitoring | 1 Hz to 10 kHz | 115 g | 58 × 22 | 24 Vdc |

| 7200/50 | Monitoring System | Vibration Monitoring System | System-Dependent | 2.1 kg | Rack-mounted | 24 Vdc |

| 330703-000-060-10-02-00 | Velomitor Sensor | Velocity Vibration Monitoring | 4.5 Hz to 5 kHz | 130 g | 60 × 24 | 24 Vdc |

❓ Frequently Asked Questions (FAQ)

Q1: What does the 330703-000-060-10-02-00 measure?

A1: It measures vibration velocity (RMS) using a piezoelectric sensing element to provide accurate real-time data for machinery condition monitoring.

Q2: Is this sensor suitable for outdoor applications?

A2: Yes, it is hermetically sealed and constructed with stainless steel, making it resistant to moisture and harsh environmental conditions.

Q3: Can I use this sensor with non-Bently Nevada systems?

A3: While optimized for Bently Nevada systems, it can be used with compatible third-party monitoring systems that accept velocity signal inputs.

Q4: What type of cable should be used with this sensor?

A4: It uses a 2-pin MIL-C-5015 connector and typically comes with armored or shielded cables to ensure signal integrity over long distances.

Q5: What maintenance is required for this sensor?

A5: The sensor is maintenance-free under normal conditions, but periodic signal verification and connector inspection are recommended.

Q6: How do I verify correct sensor operation after installation?

A6: Use a signal conditioner or vibration analyzer to check output signal and ensure proper sensitivity is maintained.

Bently Nevada 330703-000-060-10-02-00 3300 XL 11 mm Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||