| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

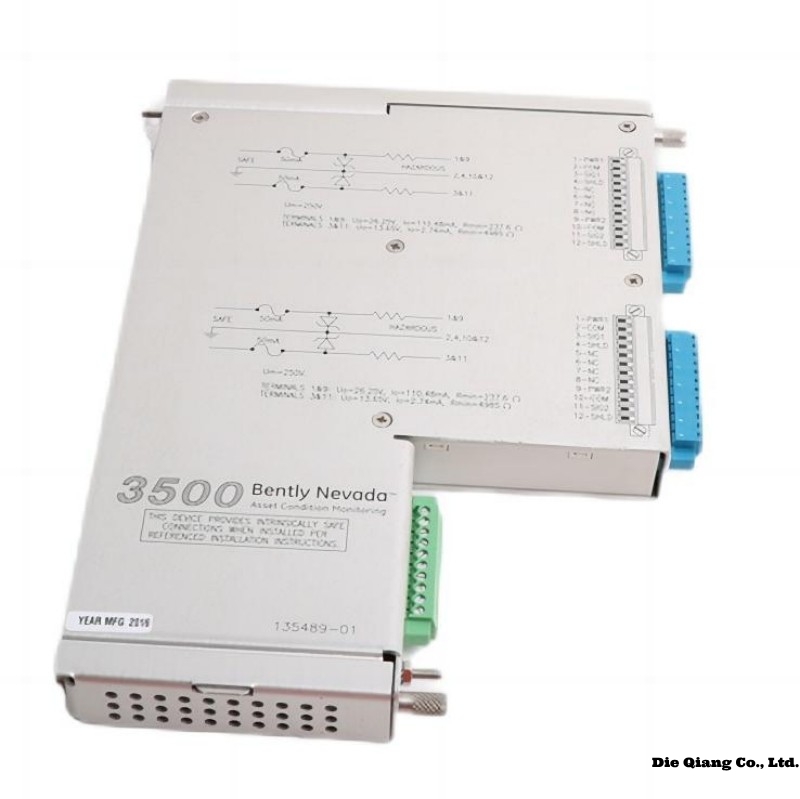

Bently Nevada 330101-00-20-10-12-05

Product Introduction

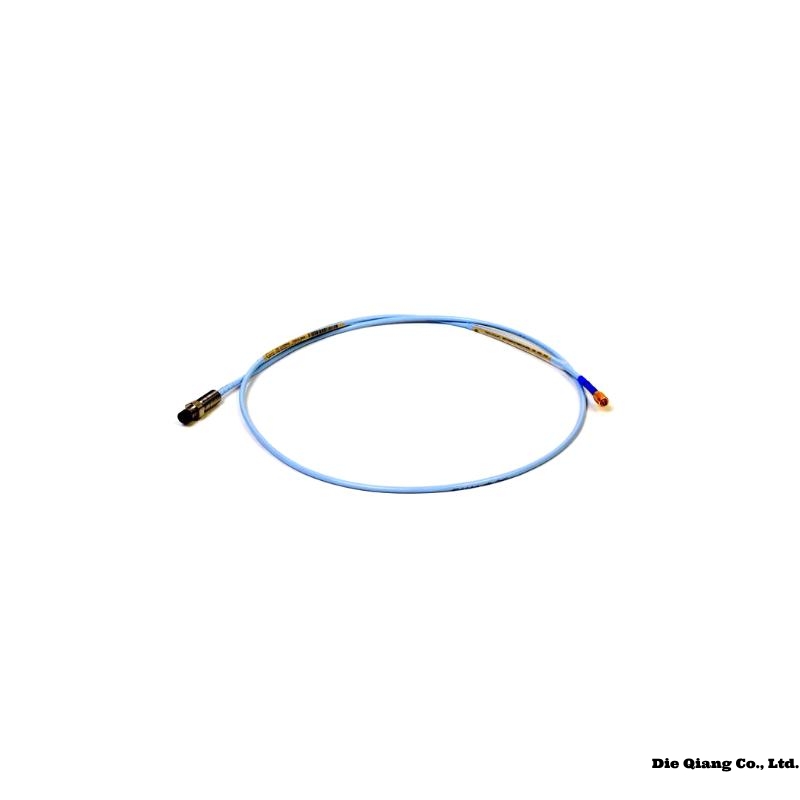

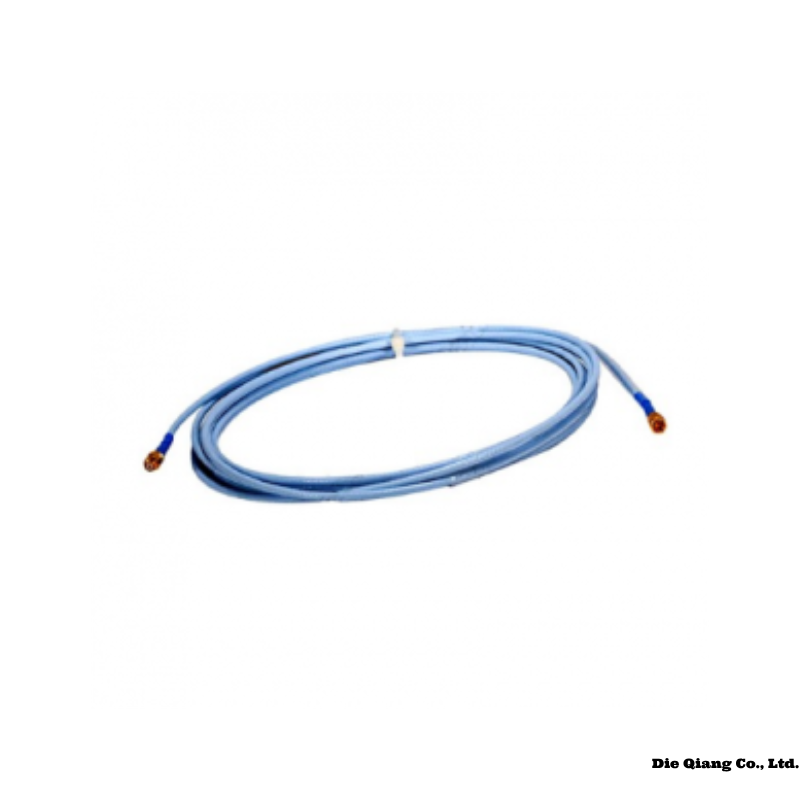

The Bently Nevada 330101-00-20-10-12-05 is a high-performance proximity probe designed for use in industrial machinery monitoring systems. As a part of the renowned 3300 XL Series, this proximity transducer system delivers accurate, reliable measurements of shaft position and vibration. It operates on the eddy-current principle, ensuring non-contact monitoring for rotating and reciprocating machinery.

This probe is engineered with rugged, corrosion-resistant materials, making it suitable for harsh environments such as petrochemical plants, power generation facilities, and large-scale manufacturing. Designed to meet API 670 compliance standards, this model ensures superior stability, linearity, and repeatability over wide temperature ranges and long-term operation.

Product Advantages

-

High Accuracy: Delivers precise shaft position and vibration data with minimal signal drift.

-

API 670 Compliant: Designed in accordance with industry-standard monitoring requirements for critical machinery.

-

Wide Temperature Operating Range: Optimized for both low and high-temperature conditions, ideal for challenging industrial settings.

-

Rugged Design: Made with hermetically sealed stainless steel housing, providing excellent resistance to corrosive environments.

-

Interchangeable System Components: Compatible with a broad range of Bently Nevada proximity systems, reducing downtime and spare part complexity.

-

Enhanced Reliability: Long-term operational stability with minimal maintenance.

-

Versatile Cable Options: Offers a variety of cable lengths and connectors to meet specific installation needs.

-

Field-Proven Technology: Installed in thousands of machines globally, trusted by industry leaders.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330101-00-20-10-12-05 |

| Probe Tip Diameter | 8 mm (0.31 in) |

| Probe Case Material | AISI 303 Stainless Steel |

| Cable Length | 5 meters (16.4 feet) |

| Thread Size | 3/8-24 UNF-2A |

| Body Length | 50 mm (2.0 in) |

| System Power Supply Voltage | -24 VDC to -28 VDC |

| System Power Consumption | ≤ 5 mA |

| Output Signal Range | 0 to -24 VDC (Non-contact displacement signal) |

| Frequency Response | 0 to 10 kHz |

| Linearity | ±0.25% of full-scale output over the calibrated range |

| Operating Temperature | -35°C to +120°C (-31°F to +248°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +351°F) |

| Weight | 0.323 kg |

| Cable length | 1 m |

| Vibration Limit | 50 g peak |

| Shock Limit | 500 g peak |

| Compliance | API 670, CE, RoHS |

Applications

The Bently Nevada 330101-00-20-10-12-05 is widely used in a variety of industrial applications, including:

-

Turbomachinery (gas turbines, steam turbines, compressors)

-

Pumps and motors

-

Gearboxes

-

Fans and blowers

-

Industrial generators

-

Crude oil refining plants

-

Chemical processing facilities

-

Power generation (nuclear, fossil, hydroelectric)

Its precise displacement measurement capabilities make it critical for machinery protection systems and predictive maintenance.

Compatible Models

This probe is compatible with the following Bently Nevada components:

-

3300 XL Proximitor Sensor

-

3300 XL Extension Cable

-

3300 XL Mounting Accessories

-

3300/16-XX Monitor Systems

-

3500 Monitoring Systems

-

7200 and 990 Vibration Monitoring Systems

Installation Instructions

-

Mounting Location: Choose a stable surface close to the shaft where radial or axial position can be measured. Avoid areas with strong electromagnetic interference.

-

Threading and Placement: Insert the probe into a pre-threaded mounting bracket using the 3/8-24 UNF-2A thread. Tighten securely with a torque wrench to specified value (~1.5 Nm).

-

Gap Setting: Adjust the probe tip to the correct target distance, usually 2 mm (80 mils) from the shaft surface, using a dial indicator or spacer tool.

-

Cable Routing: Route the probe cable securely, avoiding sharp bends or areas of vibration. Use cable clips and protective tubing where needed.

-

Connection: Attach the extension cable to the probe connector and the other end to the Proximitor sensor. Secure connectors with locknuts.

-

System Calibration: Use the monitoring system software or handheld calibrator to fine-tune signal output for accurate readings.

-

Verification: Test system output and validate readings through the monitoring display or control system.

Related Models

| Model | Description | Cable Length | Tip Diameter | Thread Size | Operating Temp |

|---|---|---|---|---|---|

| 330101-00-10-10-12-00 | Standard probe, 3 m cable | 3 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

| 330101-00-25-10-12-05 | Long cable version | 8 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

| 330101-00-15-10-12-05 | Medium cable length | 5 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

| 330101-00-05-10-12-00 | Short cable version | 1 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

| 330101-00-30-10-12-05 | Extended cable for remote installations | 10 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

| 330101-00-40-10-12-00 | Extra long cable for large machines | 12 m | 8 mm | 3/8-24 UNF | -35°C to +120°C |

Popular Bently Nevada Models

| Model | Description | Application | Cable Length | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|---|

| 330101-00-20-10-12-05 | Proximity Probe 8 mm | General machinery | 5 m | -24 VDC | Ø8 mm × 50 mm | 0.15 kg |

| 330106-05-30-10-02-00 | Proximitor Sensor | Turbomachinery monitoring | 9 m | -24 VDC | 80 mm × 25 mm × 20 mm | 0.30 kg |

| 330104-00-08-10-02-00 | Extension Cable | Signal transmission | 8 m | N/A | Cable only | 0.20 kg |

| 330130-040-00-00 | Probe Extension Kit | Probe extension | 4 m | N/A | N/A | 0.10 kg |

| 3500/42M | Vibration Monitor Module | Condition monitoring | N/A | 18–30 VDC | 100 mm × 30 mm × 75 mm | 0.45 kg |

| 3500/22M | Transient Data Interface Module | Data collection | N/A | 18–30 VDC | 120 mm × 30 mm × 75 mm | 0.50 kg |

| 7200-5-008-000-00-00 | Monitoring System | Industrial machinery | N/A | 24 VDC | 140 mm × 45 mm × 90 mm | 0.60 kg |

| 990-04-70-01-00 | Keyphasor Module | Phase reference sensing | N/A | 24 VDC | 75 mm × 25 mm × 40 mm | 0.20 kg |

FAQ (Frequently Asked Questions)

Q1: What is the maximum operating temperature of the 330101-00-20-10-12-05 probe?

A1: The probe operates reliably up to +120°C (248°F), making it suitable for high-temperature industrial environments.

Q2: Can I use this probe with non-Bently Nevada systems?

A2: This probe is specifically designed for compatibility with Bently Nevada systems. Using it with other brands may result in inaccurate readings or incompatibility.

Q3: How do I determine the correct gap setting?

A3: The typical gap is 2 mm (80 mils). Use a dial indicator or precision spacer tool for accurate adjustment during installation.

Q4: What happens if the cable length is not standard?

A4: Bently Nevada provides various cable lengths. Using a non-standard cable may require recalibration to ensure proper signal attenuation and accuracy.

Q5: Is the 330101-00-20-10-12-05 compliant with API 670?

A5: Yes, this model is fully compliant with API 670, making it ideal for critical turbomachinery monitoring applications.

Q6: How often should this probe be calibrated or replaced?

A6: Probes are typically maintenance-free but should be verified for accuracy annually. Replacement is recommended if performance degrades or after extended exposure to extreme conditions.

Bently Nevada 330101-00-20-10-12-05 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-20-10-12-05, Bently Nevada, Bently Nevada 330101-00-20-10-12-05