| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

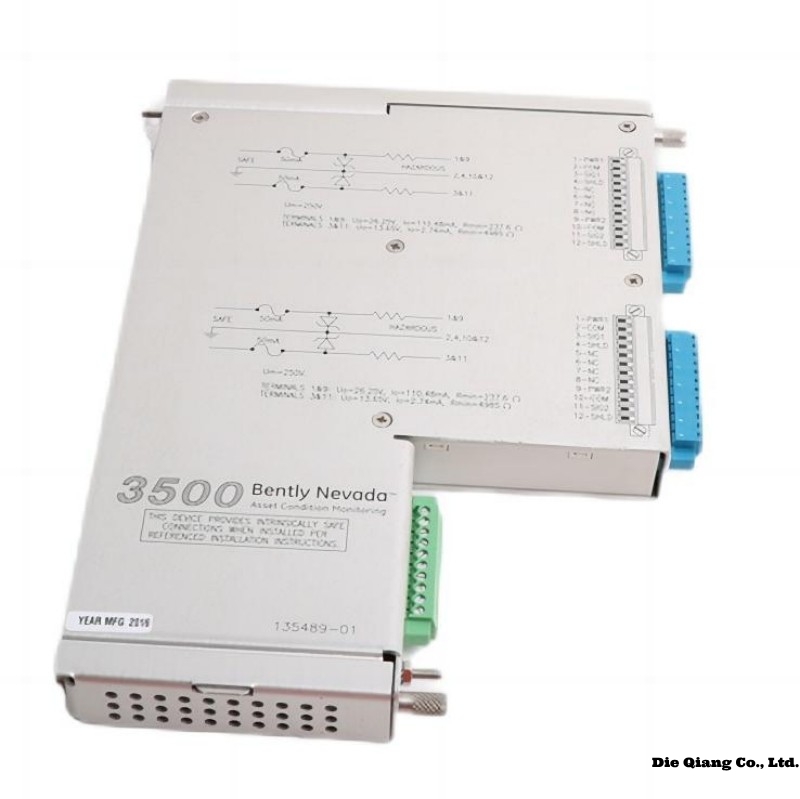

Bently Nevada 330703-000-050-10-02-00 Product Overview

The Bently Nevada 330703-000-050-10-02-00 is a high-performance vibration monitoring sensor designed for industrial applications. It is part of Bently Nevada’s extensive portfolio of condition monitoring solutions, known for reliability and precision in critical machinery protection.

This sensor is widely used in industries such as oil & gas, power generation, and manufacturing to monitor vibration levels in rotating equipment, ensuring early fault detection and preventing catastrophic failures.

Product Advantages

-

High Accuracy – Provides precise vibration measurements for reliable machinery health assessment.

-

Robust Construction – Built to withstand harsh industrial environments, including extreme temperatures and corrosive conditions.

-

Easy Integration – Compatible with Bently Nevada’s monitoring systems for seamless data acquisition and analysis.

-

Long Service Life – Durable materials and advanced engineering ensure extended operational lifespan.

-

Wide Frequency Range – Capable of detecting a broad spectrum of vibration frequencies for comprehensive monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330703-000-050-10-02-00 |

| Cable length | 1 m |

| Weight | 0.255kg |

| Operating Voltage | 18-30V DC |

| Output Signal | 4-20mA / Modbus (configurable) |

| Frequency Range | 5Hz – 10kHz |

| Temperature Range | -40°C to +85°C |

| Protection Rating | IP67 |

| Mounting Type | Threaded stud or adhesive mounting |

Applications

-

Rotating Machinery Monitoring – Pumps, compressors, turbines, and motors.

-

Predictive Maintenance – Early detection of imbalance, misalignment, and bearing wear.

-

Industrial Automation – Integration with control systems for real-time monitoring.

-

Oil & Gas – Used in offshore and onshore facilities for critical equipment protection.

Compatible Models (Product Integration)

This sensor is typically used with:

-

Bently Nevada 3500/42M – Vibration monitor.

-

Bently Nevada 3300/16 – Proximitor (for proximity probe systems).

-

Bently Nevada 3701/20 – Signal conditioner.

Installation Instructions

-

Mounting – Secure the sensor using the provided threaded stud or adhesive. Ensure proper alignment with the monitored surface.

-

Wiring – Connect the sensor to the monitoring system using shielded cables to minimize noise interference.

-

Calibration – Verify signal output using a calibrated vibration source before final commissioning.

-

Testing – Perform a functional test to ensure accurate data transmission.

Recommended Similar Models (Same Series/Related)

| Model Number | Description | Dimensions | Weight | Voltage | Frequency Range |

|---|---|---|---|---|---|

| 330703-000-050-10-01-00 | Vibration Sensor (Lower Freq.) | 50x30x20mm | 150g | 18-30V DC | 2Hz – 5kHz |

| 330703-000-050-10-03-00 | High-Temp Vibration Sensor | 50x30x20mm | 160g | 18-30V DC | 5Hz – 10kHz |

| 330703-000-050-20-02-00 | Explosion-Proof Version | 55x35x25mm | 200g | 18-30V DC | 5Hz – 10kHz |

| 330703-000-050-30-02-00 | Wireless Vibration Sensor | 50x30x20mm | 155g | Battery | 5Hz – 8kHz |

| 330703-000-050-40-02-00 | High-Sensitivity Sensor | 50x30x20mm | 150g | 18-30V DC | 1Hz – 12kHz |

| 330703-000-050-50-02-00 | Industrial IoT-Enabled Sensor | 50x30x20mm | 160g | 18-30V DC | 5Hz – 10kHz |

Top 8 Popular Bently Nevada Models

| Model Number | Type | Dimensions | Weight | Voltage | Key Feature |

|---|---|---|---|---|---|

| 3500/42M | Vibration Monitor | 200x150x80mm | 2.5kg | 24V DC | 4-channel vibration monitoring |

| 3300/16 | Proximity Probe | 8mm diameter | 100g | -18 to -24V | Shaft displacement monitoring |

| 3701/20 | Signal Conditioner | 120x80x40mm | 500g | 24V DC | Converts sensor signals |

| 1900/65A | Accelerometer | 30x20x15mm | 80g | 18-30V DC | High-frequency vibration |

| 3500/22M | Speed Monitor | 200x150x80mm | 2.5kg | 24V DC | RPM monitoring |

| 3300/25 | Velocity Sensor | 50x30x20mm | 150g | 18-30V DC | Velocity measurement |

| 3500/92 | Relay Module | 200x150x80mm | 2.5kg | 24V DC | Alarm triggering |

| 3300/45 | Temperature Sensor | 10mm diameter | 50g | N/A | Bearing temperature monitoring |

Frequently Asked Questions (FAQ)

Q1: What is the operating temperature range of the 330703-000-050-10-02-00?

A1: The sensor operates within -40°C to +85°C, making it suitable for extreme environments.

Q2: Can this sensor be used in hazardous areas?

A2: The standard model is not explosion-proof. For hazardous zones, consider 330703-000-050-20-02-00.

Q3: What output signals does this sensor support?

A3: It provides 4-20mA and Modbus output, depending on configuration.

Q4: How should the sensor be mounted for optimal performance?

A4: Use the threaded stud or adhesive mounting, ensuring direct contact with the monitored surface.

Q5: Is calibration required after installation?

A5: Yes, calibration using a known vibration source is recommended for accuracy.

Q6: What is the expected lifespan of this sensor?

A6: With proper maintenance, the sensor can last 10+ years in typical industrial conditions.

Bently Nevada 330703-000-050-10-02-00 3300 XL 11 mm Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||