| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

The Bently Nevada 330703-000-070-10-02-00 is a high-performance Proximity Sensor designed for non-contact vibration and position measurement in demanding industrial applications. As part of the Bently Nevada 3300 XL series, this transducer system is tailored for machinery monitoring, offering exceptional accuracy, reliability, and robustness even in harsh environments. It incorporates advanced eddy current sensing technology, making it suitable for rotating machinery such as turbines, compressors, pumps, and motors.

This sensor is designed to detect shaft vibration and position relative to the bearing housing or other machine structures. With a proven track record in critical machinery protection systems, the 330703-000-070-10-02-00 delivers dependable performance backed by decades of Bently Nevada innovation.

Product Advantages

-

High Accuracy: Offers precise non-contact displacement measurement using eddy current principles.

-

Robust Construction: Engineered for continuous operation in high-temperature and vibration-intensive environments.

-

Reliable Signal Transmission: Comes with integral cable and connector to ensure signal integrity across industrial distances.

-

Interchangeable Components: Fully compatible with 3300 XL Proximitor systems, allowing flexible system design and maintenance.

-

Field-Proven Performance: Extensively tested and deployed in major industries including oil and gas, power generation, and petrochemicals.

-

Extended Cable Length: This model supports a 7-meter cable, enabling installation in machinery with distant control systems.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330703-000-070-10-02-00 |

| Sensing Technology | Eddy Current |

| Probe Tip Diameter | 8 mm (0.315 in) |

| Probe Thread | 3/8-24 UNF-2A |

| Cable Length | 7 meters |

| Target Material | 4140 Steel (standard calibration) |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Vibration Limit | 10 g pk, 10–2000 Hz |

| Shock Limit | 1000 g, 1 ms duration |

| Sensitivity | 7.87 mV/μm (200 mV/mil) ±5% |

| Weight | 0.255kg |

| Voltage Supply | -24 VDC via Proximitor |

| Mounting | Threaded |

| Electrical Connector | Miniature coaxial connector |

| Cable length | 1 m |

| Compliance | CE, RoHS |

Applications

-

Gas and Steam Turbines: For detecting shaft vibration and axial displacement.

-

Centrifugal Compressors: Used in monitoring shaft position and dynamic movement.

-

Industrial Pumps: Helps prevent catastrophic failures by detecting early vibration anomalies.

-

Electric Motors and Generators: Enables condition-based maintenance and early warning detection.

-

Gearboxes: Measures shaft movement to prevent wear and tooth damage.

-

Petrochemical Plants: Operates reliably in hazardous and high-temperature conditions.

Compatible and Matched Models

The 330703-000-070-10-02-00 is typically used with the following systems and components:

-

3300 XL Proximitor Sensor (e.g., 330180-90-00)

-

3300 XL Extension Cable (e.g., 330130-080-00-00)

-

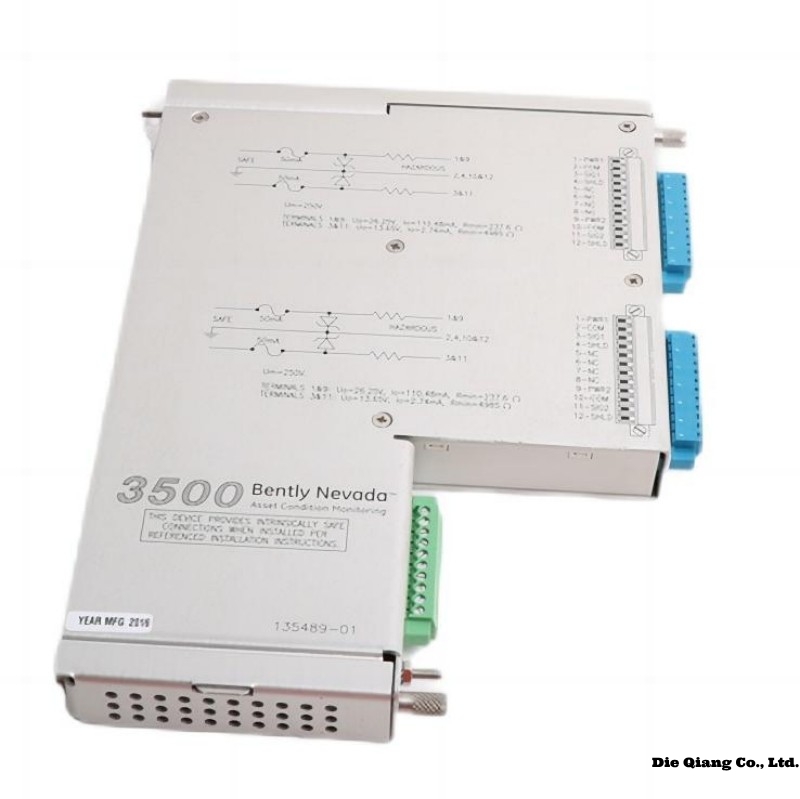

Monitoring Systems: Bently Nevada 3500 Series

-

Proximitor Cable Assembly: 330130 Series

-

Multichannel Monitoring Racks (3500/22M etc.)

-

Bently Nevada Trendmaster Pro

These combinations ensure the optimal functioning of the transducer in terms of signal output, distance measurements, and calibration integrity.

Installation Instructions

-

Mounting the Probe:

Thread the proximity probe into the measurement port using appropriate torque (typically 10-12 in-lbs). Ensure the tip is perpendicular to the target surface. -

Gap Adjustment:

Adjust the probe to achieve the recommended initial gap (typically 1.0 mm or 40 mils) using a dial indicator or feeler gauge. -

Connecting Extension Cable:

Attach the extension cable securely to the probe’s coaxial connector. Ensure the connection is tight and moisture-free. -

Connecting to Proximitor:

Plug the other end of the extension cable into the 3300 XL Proximitor Sensor, and verify system wiring integrity. -

System Calibration:

Use a multimeter or system software to check bias voltage and confirm the proper operating point. -

Verification:

Perform functional tests and system diagnostics via the monitoring system to ensure accuracy and signal stability.

6 Related Models

| Model Number | Cable Length | Thread Size | Tip Diameter | Operating Temp. | Sensitivity |

|---|---|---|---|---|---|

| 330703-000-040-10-02-00 | 4.0 m | 3/8-24 UNF-2A | 8 mm | -35°C to +177°C | 7.87 mV/μm |

| 330703-000-060-10-02-00 | 6.0 m | 3/8-24 UNF-2A | 8 mm | -35°C to +177°C | 7.87 mV/μm |

| 330703-000-100-10-02-00 | 10.0 m | 3/8-24 UNF-2A | 8 mm | -35°C to +177°C | 7.87 mV/μm |

| 330104-00-05-10-02-00 | 5.0 m | M10 x 1 | 5 mm | -35°C to +121°C | 7.87 mV/μm |

| 330106-05-30-10-02-00 | 9.0 m | 1/4-28 UNF | 5 mm | -35°C to +149°C | 7.87 mV/μm |

| 330709-000-060-10-02-00 | 6.0 m | 3/8-24 UNF-2A | 8 mm | -35°C to +177°C | 7.87 mV/μm |

8 Popular Bently Nevada Models

| Model Number | Description | Dimensions (mm) | Weight | Voltage | Application Area |

|---|---|---|---|---|---|

| 330103-00-05-10-02-00 | 5 mm Proximity Probe, 5 m cable | 60 x 5 | 150 g | -24 VDC | General Machinery Monitoring |

| 330104-00-07-10-02-00 | 5 mm Probe, 7 m cable, M10 thread | 65 x 5 | 160 g | -24 VDC | Compact Sensor Mounting |

| 330130-040-00-00 | 4 m Extension Cable for 3300 XL System | N/A | 200 g | N/A | Signal Transmission |

| 330180-90-00 | 3300 XL Proximitor Sensor | 100 x 40 x 20 | 300 g | -24 VDC | Probe Signal Conditioning |

| 3500/42M | Dynamic Vibration Monitor Module | 115 x 25 x 130 | 400 g | Rack-powered | Machine Protection |

| 3500/22M | Transient Data Interface Module | 115 x 25 x 130 | 380 g | Rack-powered | Data Collection Interface |

| 330500-02-05 | Velocity Sensor, Industrial Use | 70 x 25 | 250 g | Self-powered | Low-Frequency Vibration |

| 990-04-XX-01-00 | Accelerometer with Integrated Cable | 25 x 20 | 200 g | Self-powered | Structural Monitoring |

Frequently Asked Questions (FAQ)

Q1: What is the typical gap voltage for the 330703-000-070-10-02-00?

A1: The typical gap voltage ranges between -11 VDC and -13 VDC depending on the probe-target distance and calibration setup.

Q2: Can this probe be used with non-metallic targets?

A2: No. The probe operates using eddy current technology, which requires a conductive metallic target, typically 4140 steel or similar materials.

Q3: Is the probe hazardous-area rated?

A3: The sensor itself is not intrinsically safe by default. For hazardous locations, appropriate enclosures and intrinsic safety barriers are required.

Q4: How often should the proximity probe system be calibrated?

A4: It is recommended to perform calibration and functional testing during initial commissioning and at least annually as part of preventive maintenance.

Q5: What kind of cable is used with this probe?

A5: The probe uses a triaxial coaxial cable with high EMI shielding and is terminated with a standard miniature coaxial connector.

Q6: Is this probe backward compatible with older Bently Nevada systems?

A6: Yes, it is backward compatible with legacy 7200 and 3300 series monitoring systems, provided the full transducer system (probe, cable, proximitor) is matched.

Bently Nevada 330703-000-070-10-02-00 3300 XL 11 mm Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||