| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

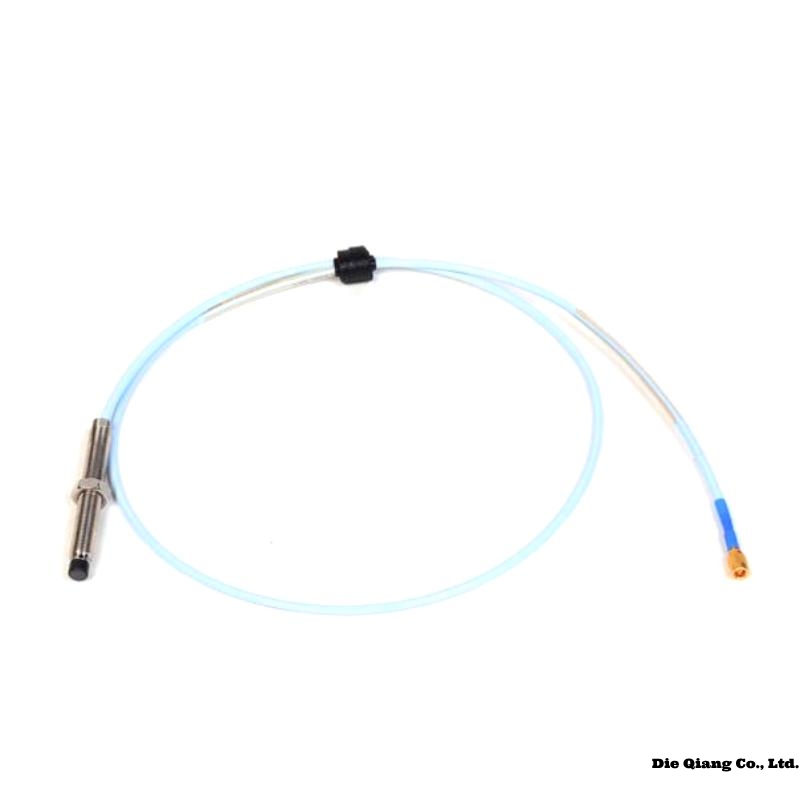

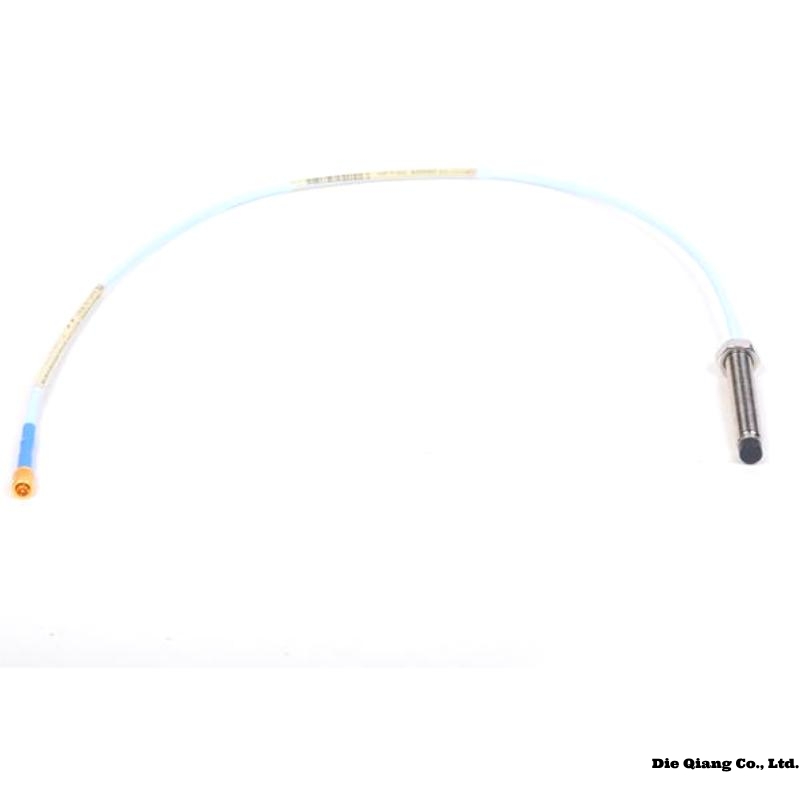

Bently Nevada 330101-00-30-10-02-05 Product Overview

The Bently Nevada 330101-00-30-10-02-05 is a high-performance vibration monitoring transducer designed for industrial machinery protection. It is part of the 3300 Series of monitoring systems, which are widely used in critical applications to ensure operational reliability and safety.

This transducer is specifically engineered to measure radial vibration in rotating machinery, providing accurate and real-time data to prevent equipment failure. It is commonly used in industries such as oil & gas, power generation, and manufacturing.

Product Advantages

-

High Accuracy: Delivers precise vibration measurements for early fault detection.

-

Robust Construction: Built to withstand harsh industrial environments, including high temperatures and corrosive conditions.

-

Easy Integration: Compatible with Bently Nevada’s 3300 monitoring systems for seamless data acquisition.

-

Long Service Life: Durable materials ensure extended operational lifespan.

-

Wide Compatibility: Works with various machinery types, including turbines, compressors, and pumps.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330101-00-30-10-02-05 |

| Type | Vibration Transducer |

| Measurement Range | 0-500 µm (peak-to-peak) |

| Frequency Response | 10 Hz to 1 kHz |

| Output Signal | 4-20 mA (Linear with vibration) |

| Power Supply | 18-30 VDC |

| Operating Temp. | -40°C to +85°C |

| Housing Material | Stainless Steel |

| Cable length | 1 m |

| Weight | 0.323 kg |

| Ingress Protection | IP67 |

Applications

-

Gas & Steam Turbines: Monitors blade and shaft vibrations.

-

Compressors: Detects imbalance or misalignment issues.

-

Pumps & Motors: Ensures smooth operation and prevents bearing failures.

-

Generators: Provides vibration data for predictive maintenance.

Compatible Models for Integration

The 330101-00-30-10-02-05 can be used with the following Bently Nevada systems:

-

3300/20 Proximitor® (Vibration sensor interface)

-

3300/25 Accelerometer (For high-frequency vibration)

-

3300/40 Proximity Transducer (For shaft displacement)

-

3300/45 Seismic Transducer (For low-frequency vibration)

Installation Instructions

-

Mounting: Secure the transducer on a stable surface near the measurement point.

-

Wiring: Connect the output leads to the monitoring system (refer to the wiring diagram).

-

Calibration: Use a known vibration source to verify signal accuracy.

-

Testing: Perform a functional test before full operation.

Recommended 6 Related Models in the 3300 Series

| Model Number | Description | Measurement Range | Output | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|---|

| 330101-00-30-10-02-03 | Radial Vibration Transducer | 0-500 µm | 4-20 mA | 18-30 VDC | 80x50x30 mm | 0.5 kg |

| 330104-00-00-10-02-00 | Axial Vibration Transducer | 0-1000 µm | 4-20 mA | 18-30 VDC | 85x55x35 mm | 0.6 kg |

| 330102-00-00-10-02-00 | High-Temp Vibration Transducer | 0-400 µm | 4-20 mA | 18-30 VDC | 80x50x30 mm | 0.5 kg |

| 330105-00-00-10-02-00 | Dual-Channel Vibration Monitor | 0-500 µm | 4-20 mA x2 | 18-30 VDC | 100x60x40 mm | 0.8 kg |

| 330106-00-00-10-02-00 | Explosion-Proof Transducer | 0-600 µm | 4-20 mA | 18-30 VDC | 90x55x35 mm | 0.7 kg |

| 330103-00-00-10-02-00 | Low-Frequency Vibration Sensor | 0-300 µm | 4-20 mA | 18-30 VDC | 80x50x30 mm | 0.5 kg |

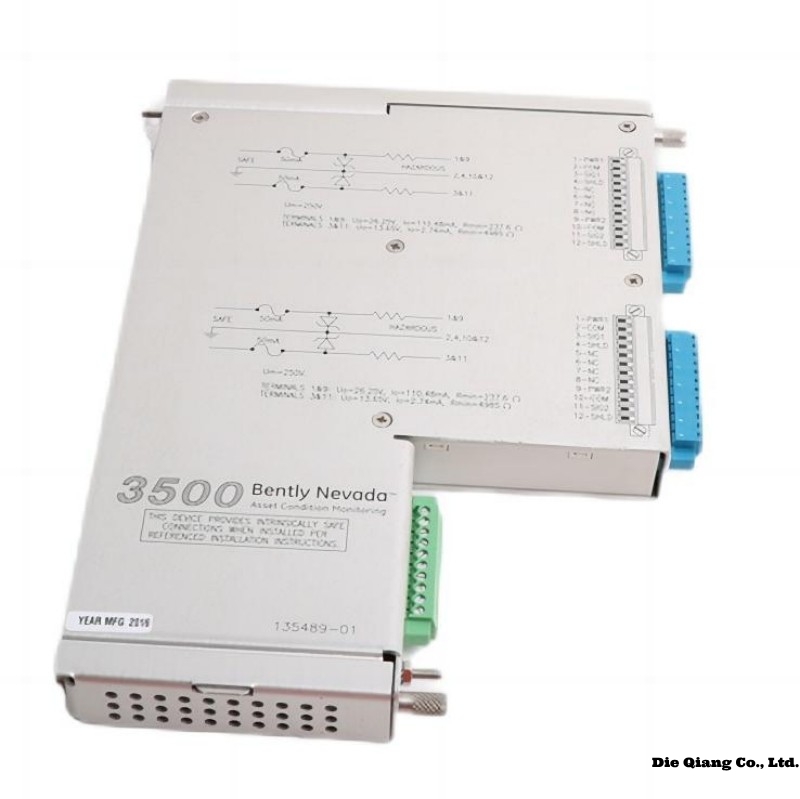

8 Popular Bently Nevada Models (Other Series)

| Model Number | Description | Key Parameter | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|

| 3500/22M | Proximity Transducer System | 2 mm range | 24 VDC | 120x80x40 mm | 1.2 kg |

| 3500/42M | Seismic Velocity Sensor | 50 mm/s range | 18-30 VDC | 90x60x30 mm | 0.9 kg |

| 1900/65A | Accelerometer | 100 g range | 5 VDC | 30x20x15 mm | 0.1 kg |

| 3701/20-01-00 | Machinery Health Monitor | 4-20 mA output | 24 VDC | 150x100x50 mm | 2.0 kg |

| 3300/16-11-02-01-00 | Proximitor® Sensor | 2 mm range | 18-30 VDC | 70x40x25 mm | 0.4 kg |

| 3500/92 | Dual-Channel Monitor | 0-500 µm range | 24 VDC | 200x150x60 mm | 3.0 kg |

| 3300/25-01-00 | Accelerometer Module | 10 g range | 18-30 VDC | 80x50x30 mm | 0.5 kg |

| 3500/15-02-00 | Temperature Monitor | -40°C to +120°C | 24 VDC | 100x70x40 mm | 1.5 kg |

FAQ (Q&A)

Q1: What is the operating temperature range of the 330101-00-30-10-02-05?

A1: It operates between -40°C to +85°C.

Q2: Can this transducer be used in explosive environments?

A2: No, for hazardous areas, consider the 330106-00-00-10-02-00 (explosion-proof model).

Q3: What is the output signal type?

A3: It provides a 4-20 mA linear output proportional to vibration.

Q4: How often should calibration be performed?

A4: Recommended calibration interval is every 12 months or after severe environmental exposure.

Q5: Is this model compatible with non-Bently Nevada systems?

A5: Yes, but optimal performance is achieved with Bently Nevada 3300/3500 series monitors.

Q6: What is the expected lifespan of this transducer?

A6: Under normal conditions, it can last 5-10 years depending on operating environment.

Bently Nevada 330101-00-30-10-02-05 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-30-10-02-05, Bently Nevada, Bently Nevada 330101-00-30-10-02-05