| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Bently Nevada 330101-00-30-10-02-00

Product Introduction

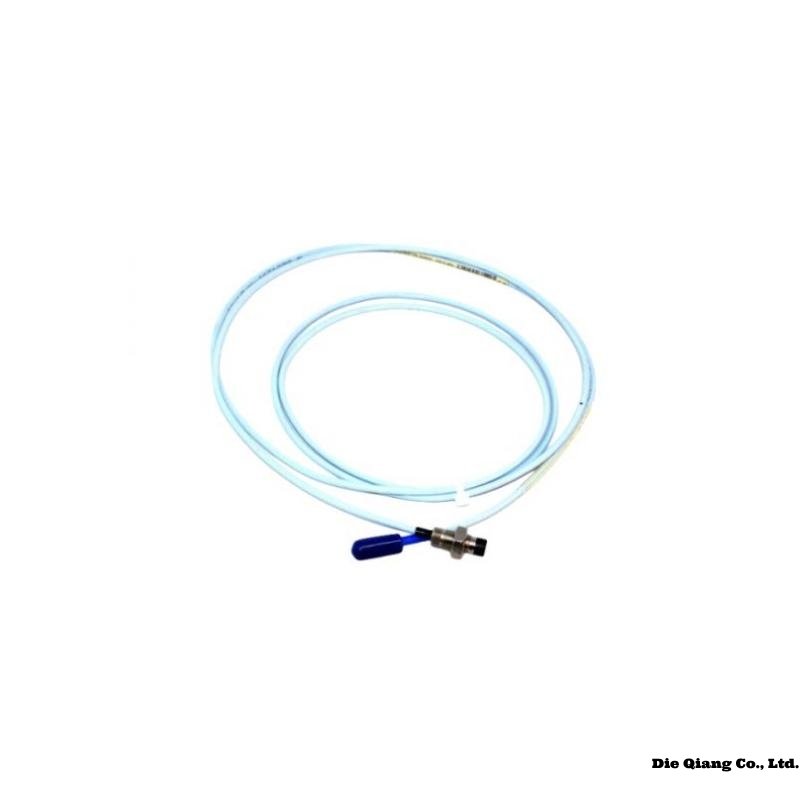

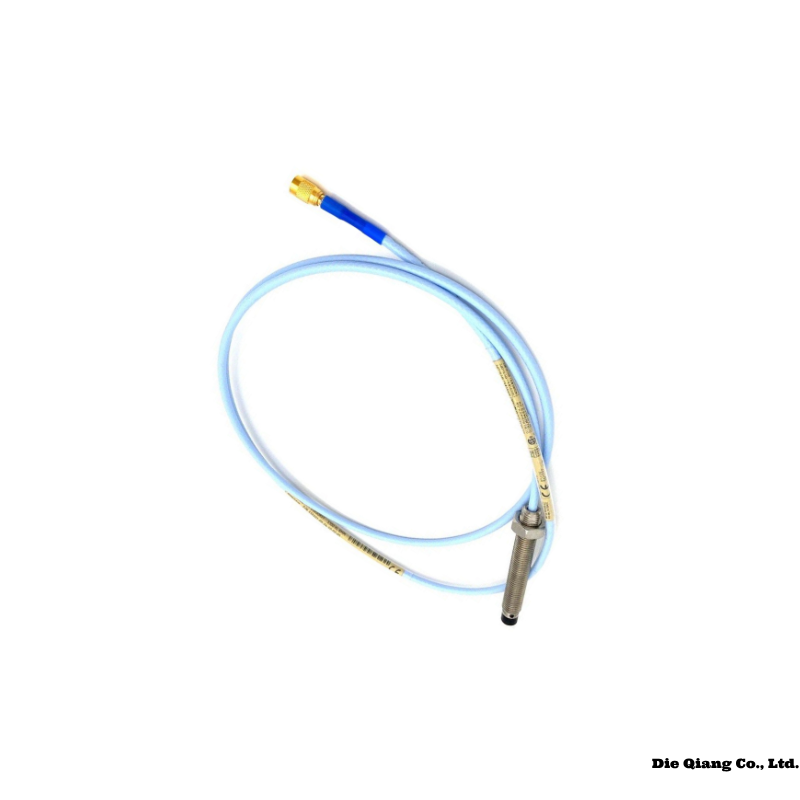

The Bently Nevada 330101-00-30-10-02-00 is a part of the 3300 XL Proximity Transducer System family, a leading solution for vibration and position monitoring in critical rotating machinery. Manufactured by Bently Nevada, a division of Baker Hughes, this sensor is known for its precision, durability, and seamless integration into advanced condition monitoring systems. It is primarily used in turbine, compressor, and pump systems where real-time machinery diagnostics are essential for safety and performance.

This specific model features a probe length of 30 inches, armor cable, and options designed for high-temperature environments and demanding industrial settings. It plays a vital role in protecting assets by detecting mechanical anomalies such as shaft misalignment, rotor imbalance, and bearing wear.

Product Advantages

-

High Accuracy: Delivers precise measurements for both static and dynamic conditions, ensuring machinery protection.

-

Rugged Design: Engineered to withstand harsh industrial environments, including high temperature and vibration zones.

-

Fully Compatible: Designed to work seamlessly with other Bently Nevada systems including 3300 XL monitors, proximitor sensors, and cabling.

-

Long Service Life: Built with corrosion-resistant materials and high-quality connectors for extended durability.

-

Ease of Integration: Comes pre-assembled with standard connector options, reducing installation time and error.

-

Industry Standard: Complies with API 670 guidelines for machinery protection, widely accepted in oil & gas, power generation, and heavy industry sectors.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-30-10-02-00 |

| Probe Thread | 3/8-24 UNF |

| Cable Type | Armor Cable |

| Cable Length | 1.0 meters |

| Connector Type | Miniature coaxial |

| System Compatibility | 3300 XL Series Transducer Systems |

| Input Voltage | -24 VDC nominal (supplied via proximitor sensor) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Linear Range | 2 mm (80 mils) |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Pressure Rating | Up to 5,000 psi (34,474 kPa) |

| Weight | 0.323 kg |

| Material | 304 Stainless Steel body and tip |

Product Applications

The Bently Nevada 330101-00-30-10-02-00 is ideal for use in a wide range of industrial applications:

-

Steam and Gas Turbines

-

Centrifugal Compressors

-

Electric Motors and Generators

-

Industrial Pumps

-

Gearboxes and Reducers

-

Petrochemical Refineries

-

Hydropower Plants

In all these applications, it serves as a critical element in predictive maintenance programs by offering continuous condition monitoring of rotating assets.

Compatible Models

The following components are commonly used in conjunction with the 330101-00-30-10-02-00 probe:

-

3300 XL Proximitor Sensor (e.g., 3300 XL 5mm or 8mm series)

-

330130 Extension Cable

-

330104 Cable Assembly

-

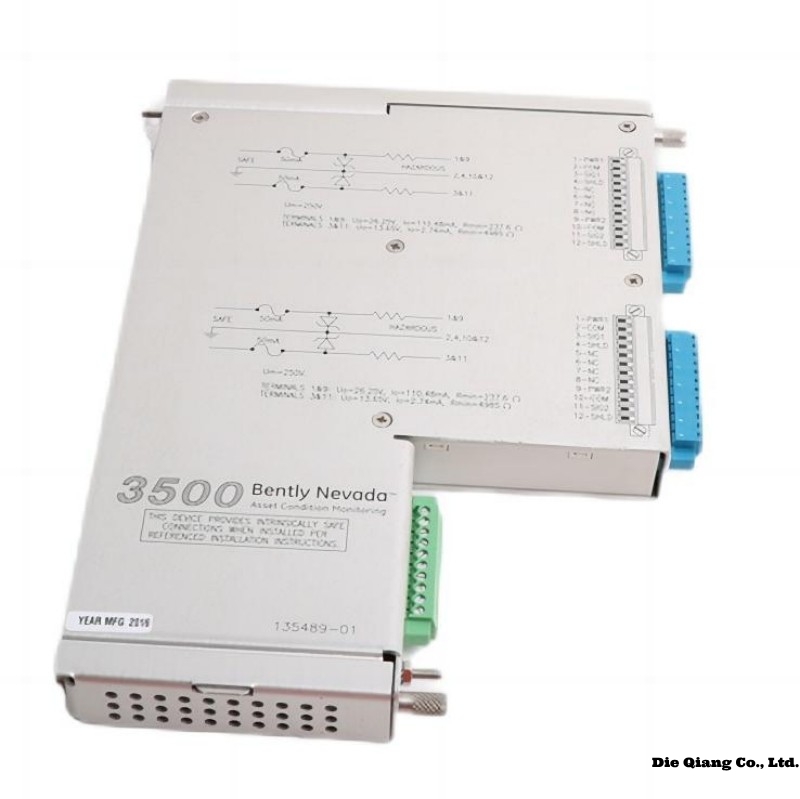

3300 Monitoring Systems (e.g., 3500 series)

-

BN 3300 XL Rack System

-

Keyphasor Modules

Installation Instructions

-

Preparation

Ensure that the mounting location is clean and free of oil, dust, or debris. Confirm that the mounting hole thread matches the probe’s 3/8-24 UNF specification. -

Mounting the Probe

Thread the probe into the mounting port. Use a torque wrench to tighten it to the recommended specification (typically 2.3 Nm or 20 in-lbs). Avoid over-tightening. -

Routing the Cable

Route the armor cable carefully to avoid sharp bends or abrasion. Use cable ties and clips to secure the cable. -

Connecting the Extension Cable

Connect the probe to the extension cable using the miniature coaxial connectors. Ensure connectors are clean and fully seated. -

Connecting to the Proximitor Sensor

Attach the extension cable to the proximitor sensor. Double-check connector orientation and lock mechanism if present. -

System Testing and Calibration

Power on the system, verify signal integrity, and perform a calibration check using standard procedures or OEM tools.

Related Models (Same Series)

| Model Number | Description | Cable Length | Thread Size | Tip Diameter | Temperature Rating |

|---|---|---|---|---|---|

| 330101-00-20-10-02-00 | 3300 XL Probe, 20″ Length, Armor Cable | 10 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

| 330101-00-25-10-02-00 | 3300 XL Probe, 25″ Length, Armor Cable | 10 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

| 330101-00-35-10-02-00 | 3300 XL Probe, 35″ Length, Armor Cable | 10 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

| 330101-00-40-10-02-00 | 3300 XL Probe, 40″ Length, Armor Cable | 10 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

| 330101-00-30-05-02-00 | 3300 XL Probe, 30″ Length, Unarmored Cable | 5 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

| 330101-00-30-10-01-00 | 3300 XL Probe, 30″ Length, Armor, Alternate Conn | 10 ft | 3/8-24 UNF | 0.190 in | -35°C to +177°C |

Popular Bently Nevada Models

| Model Number | Description | Voltage | Dimensions | Weight |

|---|---|---|---|---|

| 330104-00-10-10-02-00 | 3300 XL Extension Cable, 10 ft | N/A | 3.0 m Length × 5 mm Ø | 0.3 kg |

| 330130-040-00-00 | 3300 XL Proximitor Sensor | -24 VDC | 88 mm × 25 mm × 25 mm | 0.5 kg |

| 330106-05-30-10-02-00 | 3300 XL 8mm Proximity Probe, 30” | -24 VDC | 762 mm × 8 mm Ø | 0.75 kg |

| 330180-91-00 | 3300 XL NSv Probe for tight spaces | -24 VDC | 100 mm × 5 mm Ø | 0.2 kg |

| 330173-00-04-10-02-00 | 3300 XL High-Temperature Probe | -24 VDC | 1016 mm × 5 mm Ø | 0.85 kg |

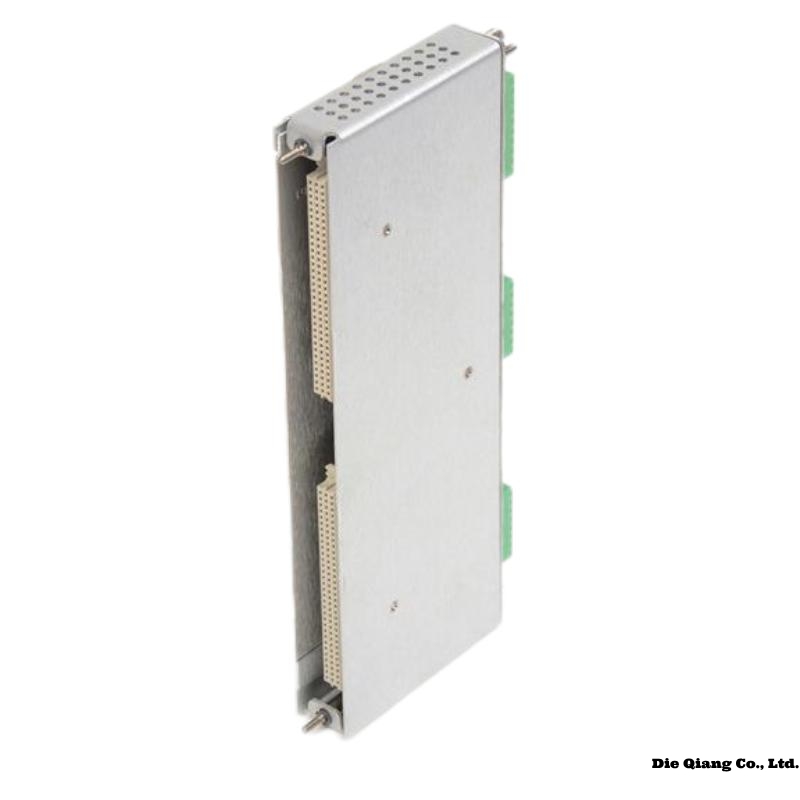

| 3500/42M-01-00 | 3500/42M Vibration Monitor Module | +24 VDC | 100 mm × 25 mm × 150 mm | 0.6 kg |

| 3500/15-05-01-00 | 3500 Power Supply Module | 85–264 VAC | 30 mm × 150 mm × 250 mm | 1.1 kg |

| 144181-01 | 3500 Rack Interface I/O Module | +24 VDC | 130 mm × 40 mm × 100 mm | 0.4 kg |

Frequently Asked Questions (FAQ)

Q1: What does the part number 330101-00-30-10-02-00 represent?

A1: It indicates a 3300 XL proximity probe with a 30-inch length, 10 ft armored cable, and standard connector configurations for typical proximitor sensor systems.

Q2: Can this probe be used in high-temperature environments?

A2: Yes, the operating temperature range of -35°C to +177°C makes it suitable for most high-temperature industrial applications.

Q3: How do I know if my probe is properly calibrated?

A3: Proper calibration can be confirmed through a proximitor sensor calibration procedure using a micrometer and verifying the linearity across the measurement range.

Q4: Is this probe compatible with older 3300 series systems?

A4: Yes, the 3300 XL series is backward compatible with legacy 3300 series systems, though performance is optimized with XL Proximitor sensors.

Q5: What happens if the cable length is modified?

A5: Cable length affects signal integrity and system calibration. Always use the factory-assembled cable lengths or recalibrate if modified.

Q6: How often should the probe be inspected or replaced?

A6: Routine inspection every 6 to 12 months is recommended. Replacement may be necessary if signal drift, physical damage, or connector wear is detected.

Bently Nevada 330101-00-30-10-02-00 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-30-10-02-00, Bently Nevada, Bently Nevada 330101-00-30-10-02-00