| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

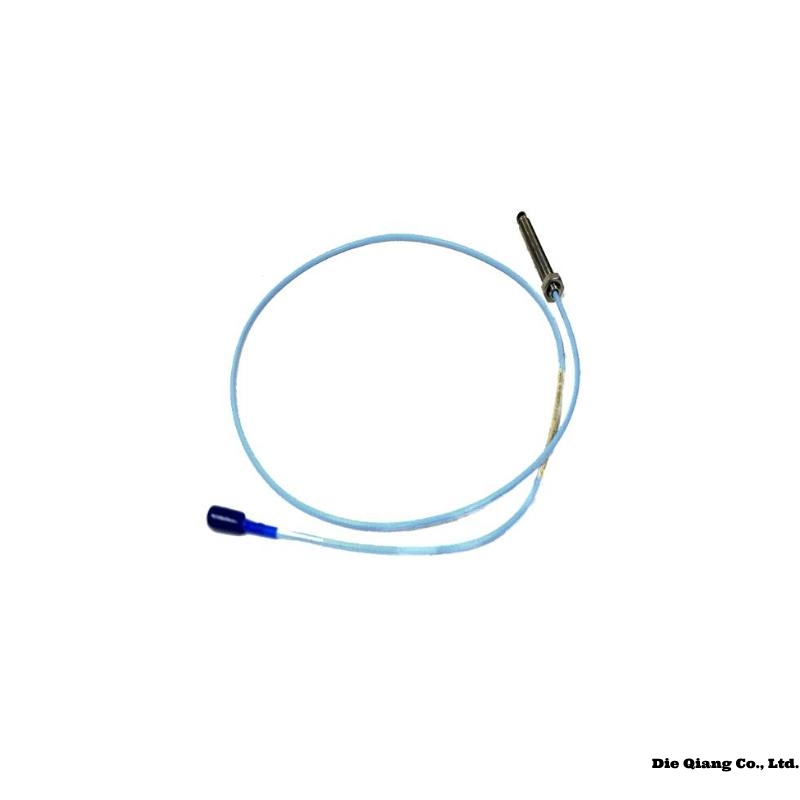

Bently Nevada 330101-00-32-10-02-05 Product Overview

The Bently Nevada 330101-00-32-10-02-05 is part of the renowned 3300 XL series, known for its exceptional reliability and precision in vibration and position measurement. Designed specifically for demanding industrial environments, this proximity probe offers highly accurate readings critical for machinery protection and condition monitoring. Its robust construction and superior performance make it the preferred choice across various industries including oil and gas, power generation, and manufacturing.

The 3300 XL 8 mm Proximity Transducer System, which includes the 330101 probe, meets API 670 requirements and supports a wide range of standard and custom configurations. Its seamless compatibility with 3300 XL extension cables and Proximitor sensors ensures optimal flexibility and ease of integration into existing systems.

Product Advantages

-

Exceptional Accuracy: Delivers precise measurements of shaft position and vibration, supporting early detection of potential mechanical failures.

-

Superior Durability: Engineered to withstand harsh industrial environments with resistance to high temperatures, moisture, and contaminants.

-

Comprehensive API 670 Compliance: Fully meets the rigorous standards set by API 670 for machinery protection systems.

-

Seamless Compatibility: Designed to integrate effortlessly with Bently Nevada’s 3300 XL series extension cables and Proximitor sensors.

-

Extended Operating Life: Reduced maintenance needs due to ruggedized construction and premium materials.

-

Enhanced Signal Stability: Advanced shielding against electromagnetic interference ensures highly stable signal output even in electrically noisy environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Probe Body Material | Stainless Steel |

| Cable Length | 32 inches (812.8 mm) |

| Connector Type | Miniature coaxial connector |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Voltage Range | -24 VDC to -28 VDC |

| Sensitivity | 200 mV/mil (7.87 mV/µm) |

| System Performance | ±5% over calibrated range |

| Linearity Range | 0.25 to 2.0 mm (10 to 80 mils) |

| Pressure Resistance | Up to 1000 psi |

| Vibration Limit | 20 g pk-pk (5 to 2000 Hz) |

| Compliance Certification | API 670, CE, RoHS |

Applications

-

Rotating Machinery Monitoring: Suitable for turbines, compressors, pumps, and motors for continuous vibration and position monitoring.

-

Condition Monitoring Systems: Integral part of predictive maintenance setups to ensure early detection of wear, misalignment, or imbalance.

-

Turbomachinery Protection: Critical in safeguarding high-value rotating assets in petrochemical, power, and processing plants.

-

OEM Equipment Integration: Used by original equipment manufacturers for embedded machinery protection.

-

Research and Development: Deployed in industrial labs for dynamic behavior studies of mechanical systems.

-

Nuclear and Power Plants: Ensures reliable performance monitoring under extreme conditions.

Compatible Models

The 330101-00-32-10-02-05 is compatible with the following Bently Nevada products:

-

3300 XL Extension Cables (e.g., 330130-045-00-00)

-

3300 XL Proximitor Sensors (e.g., 330180-90-00)

-

3300 XL Series Monitoring Systems

-

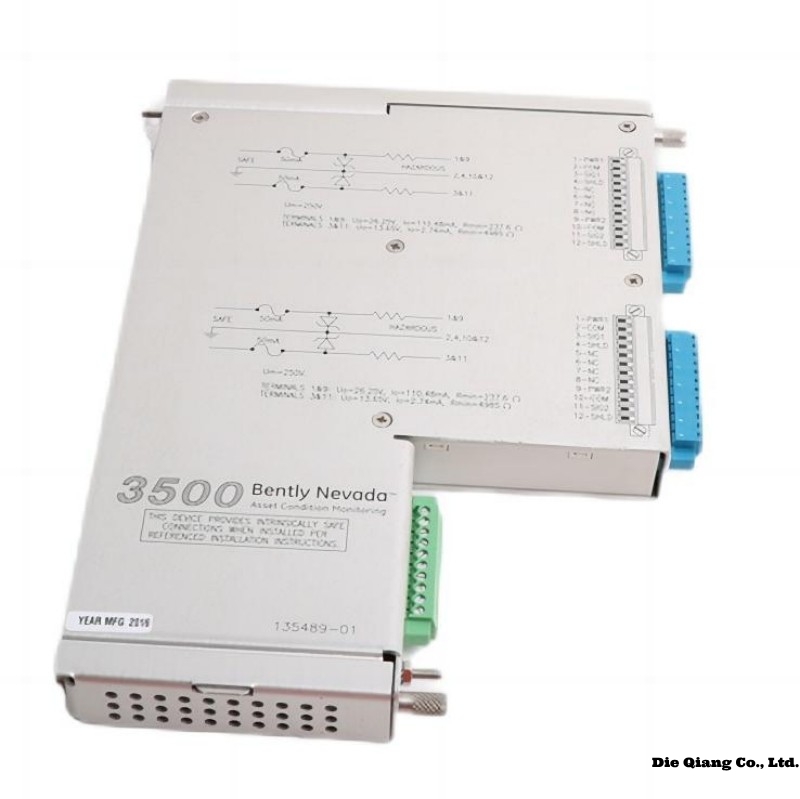

3500 Series Monitoring Systems

-

7200 Series Proximity Transducers

-

Custom Solutions based on Bently Nevada proximity measurement technologies

Installation Instructions

-

Preparation: Verify part number and configuration to match system requirements.

-

Mounting the Probe: Carefully insert the probe into the machine housing, ensuring the tip maintains the required gap to the shaft.

-

Securing the Probe: Tighten the lock nut firmly to prevent loosening under vibration.

-

Cable Routing: Route the extension cable away from high-voltage lines and sources of EMI.

-

Connecting the System: Attach the probe cable to the extension cable, and connect it to the Proximitor sensor.

-

Gap Adjustment: Calibrate the system to maintain the target gap voltage (~-10 VDC at normal operating distance).

-

Verification: Perform a system check to ensure the probe is delivering correct readings according to specifications.

-

Final Inspection: Ensure all fittings are tight, cables are secured, and protective covers are replaced.

Recommended Related Models (Same Series)

| Model | Description | Key Specifications |

|---|---|---|

| 330101-00-10-10-02-00 | 8 mm Proximity Probe, 10 ft cable | Voltage: -24VDC, Temp: -35°C to +177°C, Weight: 0.32 kg |

| 330101-00-20-10-02-00 | 8 mm Proximity Probe, 20 ft cable | Voltage: -24VDC, Temp: -35°C to +177°C, Weight: 0.33 kg |

| 330101-00-40-10-02-00 | 8 mm Proximity Probe, 40 ft cable | Voltage: -24VDC, Temp: -35°C to +177°C, Weight: 0.36 kg |

| 330103-00-05-10-02-00 | 5 mm Proximity Probe, 5 ft cable | Voltage: -24VDC, Temp: -35°C to +177°C, Weight: 0.28 kg |

| 330104-00-10-10-02-00 | 11 mm Proximity Probe, 10 ft cable | Voltage: -24VDC, Temp: -35°C to +177°C, Weight: 0.40 kg |

| 330105-02-12-10-02-00 | High-Temperature 8 mm Probe, 12 ft cable | Voltage: -24VDC, Temp: -54°C to +204°C, Weight: 0.34 kg |

8 Popular Bently Nevada Models

| Model | Description | Dimensions | Weight | Voltage |

|---|---|---|---|---|

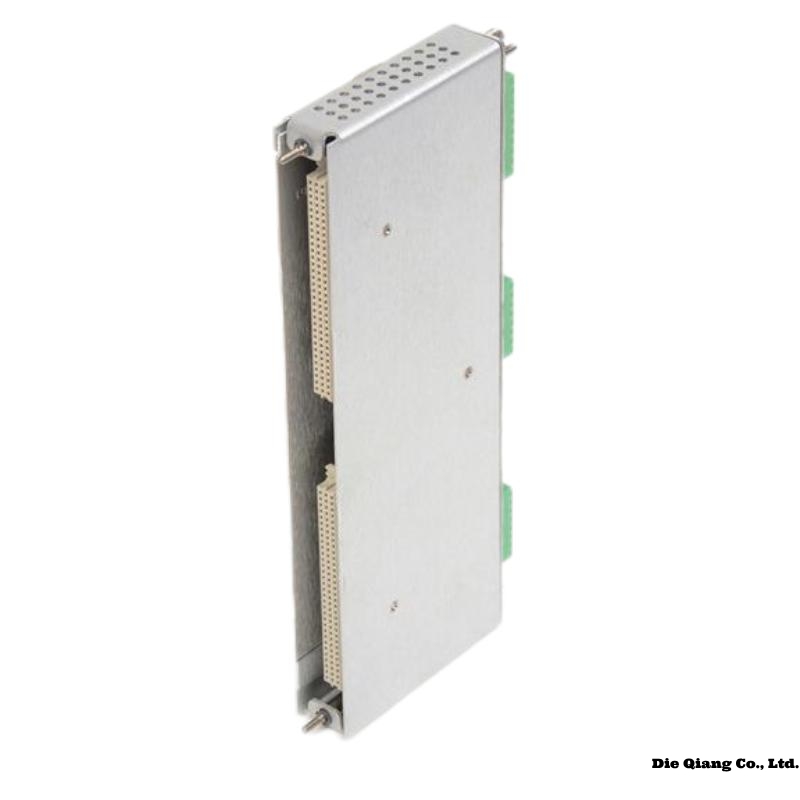

| 3500/22M | Transient Data Interface | 250 mm × 24 mm × 241 mm | 1.2 kg | 18–30 VDC |

| 3500/42M | Proximitor/Seismic Monitor | 250 mm × 24 mm × 241 mm | 1.3 kg | 18–30 VDC |

| 3500/93 | LCD Display Module | 114 mm × 167 mm × 45 mm | 0.8 kg | 24 VDC |

| 3300 XL 8 mm | Proximity Probe System | Varies by configuration | 0.35 kg | -24 to -28 VDC |

| 330130-045-00-00 | Extension Cable 45 ft | 45 ft length | 0.25 kg | Passive |

| 330180-90-00 | Proximitor Sensor 90° | 110 mm × 76 mm × 50 mm | 0.6 kg | -24 to -28 VDC |

| 7200 5mm Series | Proximity Transducer | 5 mm tip size | 0.29 kg | -24 to -28 VDC |

| 1900/65A | Vibration Monitor | 144 mm × 72 mm × 150 mm | 1.1 kg | 85–264 VAC |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 330101-00-32-10-02-05?

A1: The primary function is to measure the relative position and vibration of rotating shafts, helping to protect machinery from damage.

Q2: Can the 330101-00-32-10-02-05 probe be used in high-temperature environments?

A2: Yes, it operates reliably in environments ranging from -35°C to +177°C, making it suitable for many industrial applications.

Q3: Is this probe compatible with non-Bently Nevada monitoring systems?

A3: Although optimized for Bently Nevada systems, it may be integrated with other systems if proper signal matching is ensured.

Q4: How should the probe be mounted for best performance?

A4: The probe must be securely mounted perpendicular to the shaft surface, with precise gap adjustment and shielding from EMI sources.

Q5: What maintenance does the probe require?

A5: Routine visual inspections for cable wear and connector integrity, along with periodic signal verification, are recommended.

Q6: How does cable length affect probe performance?

A6: The system must be calibrated based on the probe and cable length combination to maintain sensitivity and accuracy within specifications.

Bently Nevada 330101-00-32-10-02-05 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-32-10-02-05, Bently Nevada, Bently Nevada 330101-00-32-10-02-05