| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

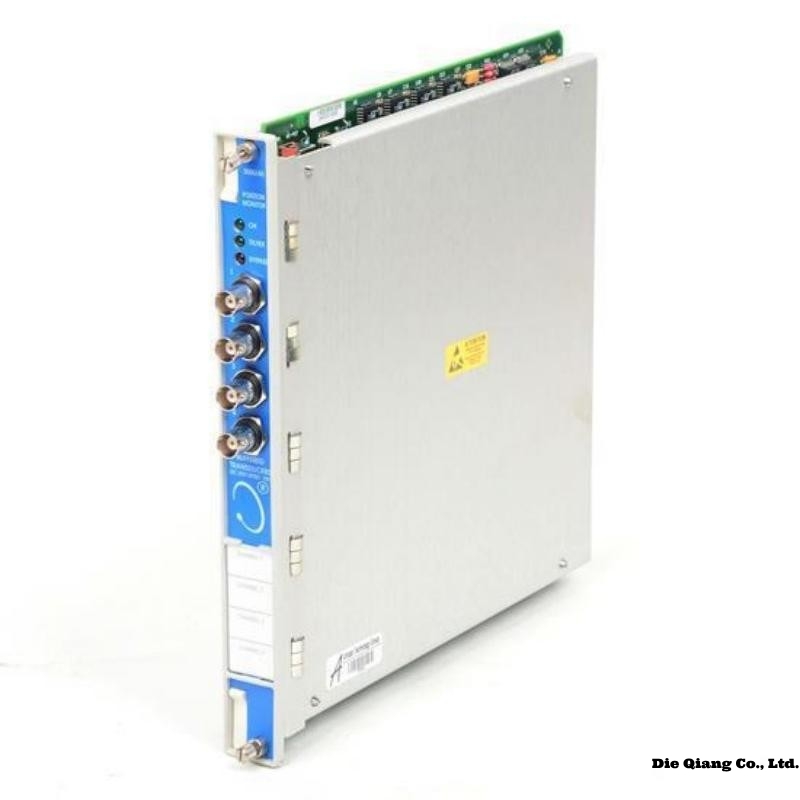

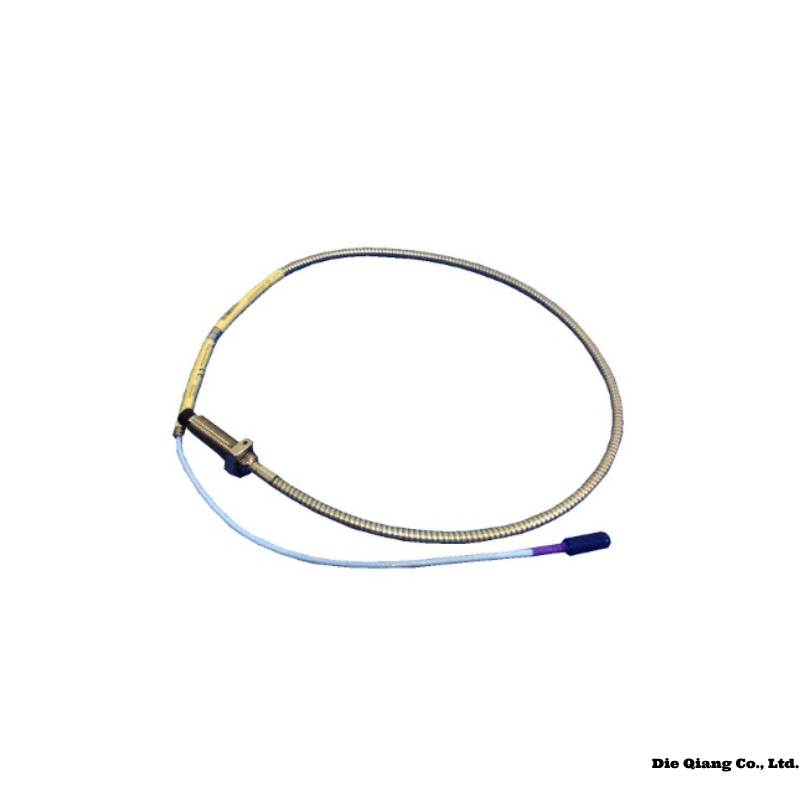

Bently Nevada 330703-000-050-10-01 Proximity Probe Assembly

Product Introduction

The Bently Nevada 330703-000-050-10-01 is a high-performance proximity probe assembly that forms part of the renowned 3300 XL series from Bently Nevada. Designed to monitor and measure the vibration, position, and displacement of rotating machinery, this proximity probe is a vital component in predictive maintenance systems across industrial facilities.

The 330703-000-050-10-01 combines a probe, extension cable, and Proximitor® sensor into a robust and reliable assembly that is known for its precise output and rugged design. It is optimized for seamless compatibility with the 3300 XL series Proximitor sensors, ensuring high accuracy, reliability, and long-term performance in challenging environments, including oil & gas, power generation, and manufacturing sectors.

This model is engineered in accordance with the API 670 standard for vibration monitoring systems, making it a dependable solution for machinery protection applications.

Product Advantages

-

High Reliability: Built for critical rotating machinery, this probe assembly provides precise and stable readings, even under extreme environmental conditions.

-

API 670 Compliance: Designed to meet the rigorous industry standards for machinery protection and vibration monitoring.

-

Flexible Configuration: With various cable lengths and connector options, the 330703 series supports multiple configurations to suit diverse application needs.

-

Excellent Linearity and Accuracy: Offers accurate vibration and displacement measurements, helping in proactive maintenance planning.

-

Robust Construction: The probe and cable are sealed for protection against moisture, oil, and contaminants.

-

Long Service Life: Resistant to mechanical wear, EMI interference, and thermal stress, which ensures longevity and minimal maintenance.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330703-000-050-10-01 |

| Probe Length | 50 mm (2.0 in) |

| Cable Length | 5 m (16.4 ft) |

| Connector Type | Miniature coaxial |

| Power Supply | -24 VDC via Proximitor® sensor |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Measurement Range | 0 to 2 mm (80 mils) |

| Linearity | Within ±1% of full-scale range |

| Operating Temperature | -35°C to +120°C (-31°F to +248°F) |

| Storage Temperature | -40°C to +177°C (-40°F to +350°F) |

| Frequency Range | 0 to 10 kHz |

| Environmental Protection | IP65-rated when properly installed |

| Compliance | API 670, CE, RoHS |

| Probe Thread Size | 3/8-24 UNF-2A |

| Weight | 0.255kg |

| Cable length | 1 m |

| Material | Stainless steel housing |

Product Applications

-

Gas and Steam Turbines

-

Compressors (Centrifugal and Reciprocating)

-

Electric Motors

-

Pumps

-

Gearboxes

-

Industrial Fans and Blowers

-

Generators and Alternators

This proximity probe assembly is essential for machine condition monitoring and protection systems where vibration, displacement, or thrust measurements are critical for operational safety and efficiency.

Compatible Models

The 330703-000-050-10-01 is designed to work seamlessly with:

-

3300 XL Proximitor® Sensor (model 330180 or 330980 series)

-

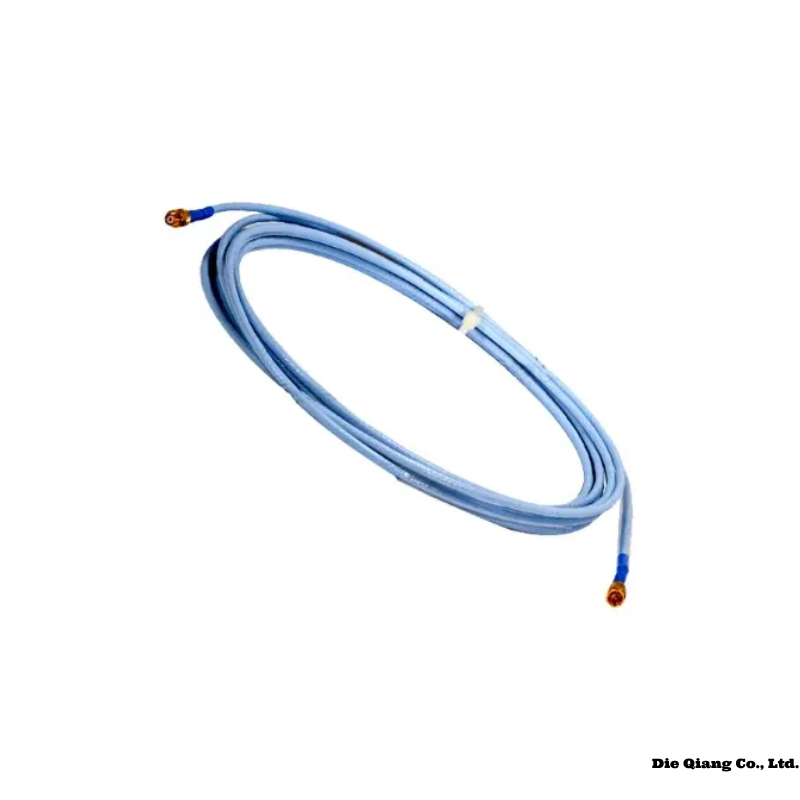

3300 XL Extension Cable (model 330130 series)

-

3300 XL Monitoring Systems (e.g., 3500 series monitors)

-

BN 3500/25 and 3500/42M Modules

-

Legacy 7200 or 3300 monitoring systems with adaptors

Installation Instructions

-

Preparation: Ensure the shaft surface is clean and the mounting location for the probe is flat and perpendicular to the axis of measurement.

-

Mounting the Probe: Thread the proximity probe into the mounting port until the tip is approximately 1 mm (40 mils) from the shaft. Use the supplied jam nut to secure the probe.

-

Cable Routing: Route the cable carefully to avoid sharp bends and interference. Use cable clamps to secure the cable.

-

Connecting the Extension Cable: Attach the extension cable to the probe connector and tighten the coupling nut securely.

-

Connect to Proximitor Sensor: Connect the other end of the extension cable to the Proximitor® sensor input.

-

System Testing: Verify signal output with a Bently Nevada signal conditioner or 3500 monitor. Confirm linear response and sensitivity.

-

Calibration and Alignment: Calibrate per API 670 standards or manufacturer recommendations. Fine-tune probe gap using a dial gauge.

6 Related Models (Same Series)

| Model | Probe Length | Cable Length | Thread Size | Output Sensitivity | Temperature Range |

|---|---|---|---|---|---|

| 330703-000-020-10-01 | 20 mm | 5 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

| 330703-000-030-10-01 | 30 mm | 5 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

| 330703-000-080-10-01 | 80 mm | 5 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

| 330703-000-100-10-01 | 100 mm | 5 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

| 330703-000-050-05-01 | 50 mm | 0.5 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

| 330703-000-050-15-01 | 50 mm | 15 m | 3/8-24 UNF | 200 mV/mil | -35°C to +120°C |

8 Popular Bently Nevada Models

| Model | Function | Dimensions (mm) | Weight | Voltage | Application |

|---|---|---|---|---|---|

| 330103-00-05-10-02-00 | Proximity Probe | 80 × 8 | 250 g | -24 VDC | Vibration/Thrust monitoring |

| 330104-00-12-10-02-00 | Proximity Probe | 120 × 8 | 310 g | -24 VDC | Shaft vibration detection |

| 330130-040-00-00 | Extension Cable | 4000 mm | 400 g | N/A | Connects probe to sensor |

| 330180-91-00 | Proximitor Sensor | 96 × 30 × 28 | 500 g | -24 VDC | Converts probe signal |

| 330980-50-05 | High-Temp Proximitor Sensor | 120 × 35 × 30 | 530 g | -24 VDC | High-temp environments |

| 3500/42M | Vibration Monitor Module | 190 × 30 × 120 | 800 g | 18–30 VDC | Monitors dynamic signals |

| 3500/22M | Transient Data Interface Module | 120 × 30 × 130 | 620 g | 24 VDC | Real-time data acquisition |

| 7200-50 Series | Legacy Monitoring System | Various | Various | 24 VDC | General-purpose vibration system |

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the 330703-000-050-10-01 probe?

A1: It is used for non-contact measurement of shaft position and vibration in rotating machinery. It converts physical displacement into electrical signals used for condition monitoring.

Q2: Is this model compliant with API 670 standards?

A2: Yes, the 330703 series is fully compliant with API 670 standards for vibration monitoring and machinery protection.

Q3: Can I use this probe in high-temperature environments?

A3: While the standard version supports up to 120°C, for higher temperatures, the 330980 series Proximitor® sensors with high-temp capabilities should be used in combination.

Q4: How do I determine the correct probe gap?

A4: The probe gap is typically set around 1 mm (40 mils) but should be fine-tuned using a dial indicator for accuracy during installation.

Q5: What is the difference between this model and 330703-000-080-10-01?

A5: The main difference lies in the probe length. The 330703-000-080-10-01 has an 80 mm probe compared to the 50 mm in the 330703-000-050-10-01, allowing deeper mounting points.

Q6: What tools are recommended for installation?

A6: A standard torque wrench, dial gauge, jam nut wrench, and alignment tools for shaft positioning are commonly used for accurate installation.

Bently Nevada 330703-000-050-10-01 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330703-000-050-10-01, Bently Nevada, Bently Nevada 330703-000-050-10-01