| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

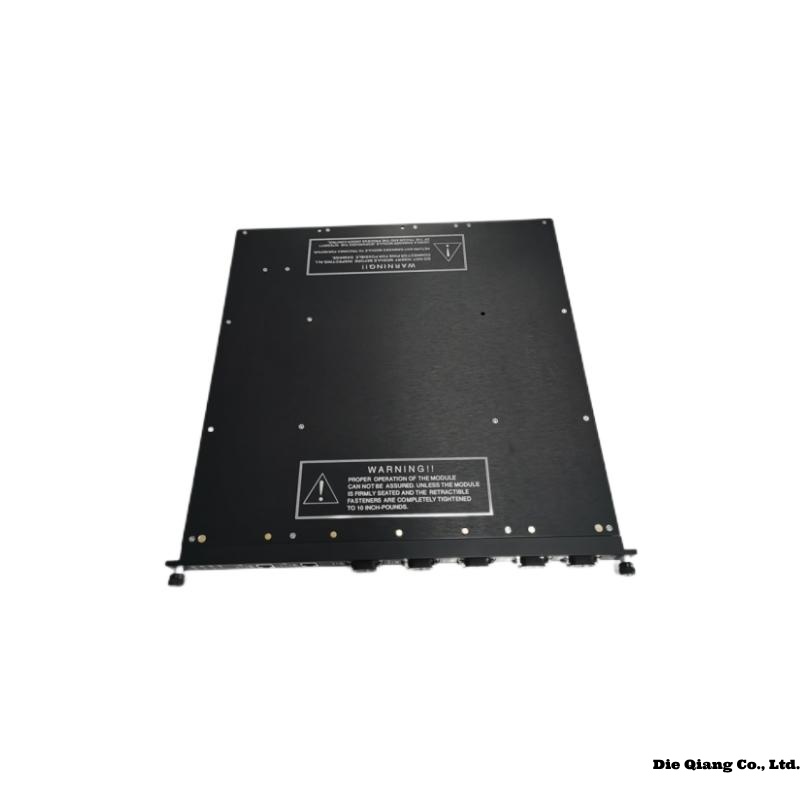

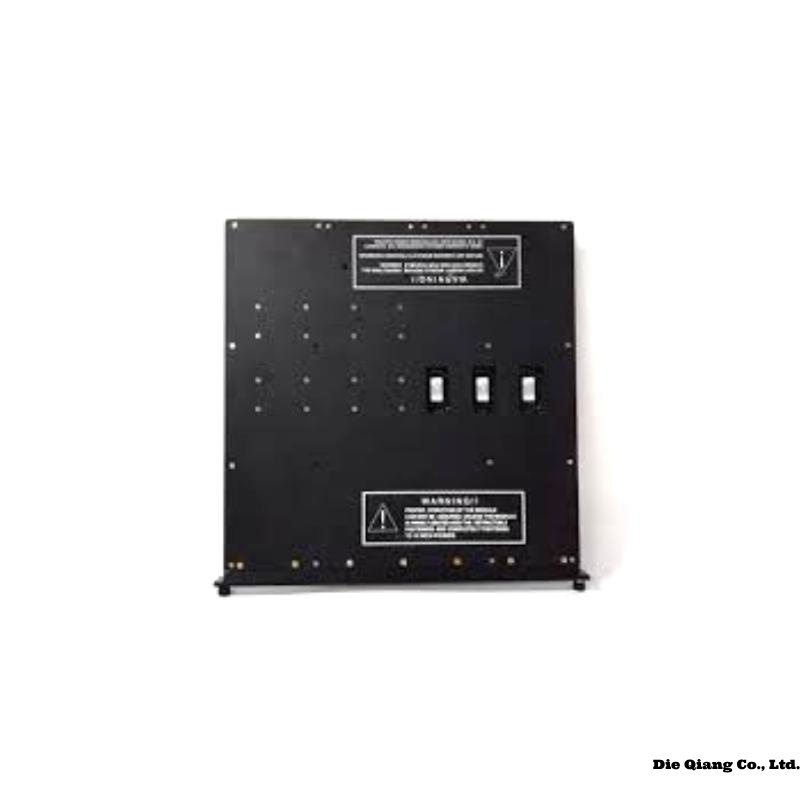

Triconex 3603T Detailed Product Overview

Product Introduction

The Triconex 3603T is a high-performance main processor module designed for use within the Triconex Tricon safety and critical control system. This module is an integral part of the Tricon triple modular redundant (TMR) architecture, which ensures maximum system reliability and availability in safety-critical applications such as emergency shutdown (ESD), burner management, turbine control, and other high-integrity process operations.

With an emphasis on fault tolerance, diagnostics, and continuous operation, the 3603T processor module coordinates logic execution, manages system communication, and facilitates diagnostics and data acquisition in a secure and deterministic environment. This makes it an essential element for industries seeking to comply with SIL 3 and SIL 4 safety standards under IEC 61508.

The module provides high-speed processing capabilities, advanced I/O data handling, and seamless communication with other Tricon modules, delivering a dependable solution for critical industrial automation needs.

Product Advantages

-

Triple Modular Redundancy (TMR) architecture ensures fault-tolerant operation and uninterrupted control even in the presence of hardware failures.

-

Certified SIL 3/4 Compliance, meeting international safety standards for critical process applications.

-

Real-time Diagnostics allow operators to quickly identify and resolve issues, reducing system downtime.

-

Hot-Swap Capability enables module replacement without shutting down the system, ensuring continuous operation.

-

High-Speed Data Processing and robust communication capabilities ensure efficient control system management.

-

Proven Field Reliability in power, oil & gas, chemical, and other process industries, with a long lifespan and minimal maintenance requirements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Triconex 3603T |

| System Architecture | Triple Modular Redundant (TMR) |

| Processor Type | High-speed 32-bit microprocessor |

| Execution Time | < 25 milliseconds per logic scan cycle |

| Communication Ports | 2 x Ethernet, 1 x serial |

| Input Voltage | 5.1 VDC (supplied via backplane) |

| Power Consumption | 10W |

| Operating Temperature | 0°C to +60°C (32°F to 140°F) |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 190 x 100 x 40 mm |

| Weight | 3.63 kg |

| Mounting Type | Rack-mounted in Tricon main chassis |

| Certifications | CE, TUV, ATEX, IEC 61508 SIL 3/4 |

Applications

The Triconex 3603T is widely used in various industrial sectors where high reliability and safety are paramount:

-

Emergency Shutdown Systems (ESD)

Used to safely shut down plant operations in the event of unsafe conditions. -

Burner Management Systems (BMS)

Controls combustion processes and ensures safety in power generation and refineries. -

Turbomachinery Control

Provides precise and safe control for turbines in oil & gas and petrochemical industries. -

Fire and Gas Systems (F&G)

Monitors environmental parameters and triggers alarms or shutdowns when hazardous gases or flames are detected. -

High Integrity Pressure Protection Systems (HIPPS)

Prevents over-pressurization by providing fast-acting shutdowns in pipelines. -

Nuclear and Fossil Power Plants

Ensures safe operation and emergency response in critical infrastructure.

Compatible Models

The Triconex 3603T is designed to work in conjunction with various Tricon modules, including but not limited to:

-

Triconex 8110 – Main chassis for processor module mounting

-

Triconex 3625 – I/O communication module

-

Triconex 3700A – Analog input module

-

Triconex 3721 – Digital input module

-

Triconex 3805E – Digital output module

-

Triconex 9853-610 – Engineering workstation software

Installation Instructions

-

Power Down the System (if not hot-swappable):

Ensure system power is off before installing to avoid electrical hazards. -

Rack Preparation:

Install the 3603T module into the designated slot in the Tricon 8110 chassis. Make sure guide rails are aligned. -

Insert the Module:

Slide the module firmly into the slot until the backplane connectors are fully engaged. -

Secure the Module:

Use screws or latching mechanisms provided to secure the module in place. -

Check System LEDs:

Upon powering up the system, verify module LEDs to ensure proper boot and diagnostics. -

Configure via Triconex Workstation Software:

Set up logical addressing, perform self-diagnostics, and load logic through engineering software. -

Perform Validation and Testing:

Run system checks and simulate process variables to confirm operational readiness.

6 Related Models

| Model | Description | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| Triconex 3604E | Enhanced main processor module | 5.1 VDC | 35 x 285 x 234 | 1.6 |

| Triconex 3619 | Memory expansion module | 5.1 VDC | 35 x 285 x 234 | 1.3 |

| Triconex 3625 | I/O communication module | 5.1 VDC | 35 x 285 x 234 | 1.4 |

| Triconex 3700A | Analog input module | 5.1 VDC | 35 x 285 x 234 | 1.5 |

| Triconex 3721 | Digital input module | 5.1 VDC | 35 x 285 x 234 | 1.4 |

| Triconex 3805E | Digital output module | 5.1 VDC | 35 x 285 x 234 | 1.5 |

8 Popular Triconex Models

| Model | Function | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| Triconex 3008 | Main processor chassis | 5.1 VDC | 448 x 483 x 234 | 7.2 |

| Triconex 3625 | Communication module | 5.1 VDC | 35 x 285 x 234 | 1.4 |

| Triconex 3700A | Analog input module | 5.1 VDC | 35 x 285 x 234 | 1.5 |

| Triconex 3721 | Digital input module | 5.1 VDC | 35 x 285 x 234 | 1.4 |

| Triconex 3805E | Digital output module | 5.1 VDC | 35 x 285 x 234 | 1.5 |

| Triconex 9853-610 | Engineering software toolkit | N/A | N/A | Software only |

| Triconex 8312 | Power supply module | 24 VDC | 60 x 285 x 234 | 2.1 |

| Triconex 4211 | Multiplexer interface module | 5.1 VDC | 35 x 285 x 234 | 1.3 |

Frequently Asked Questions (FAQ)

Q1: What is the main function of the Triconex 3603T module?

A1: The Triconex 3603T is a main processor module that performs control logic execution, communication coordination, and diagnostics management within the Tricon safety system.

Q2: Can the 3603T be replaced while the system is running?

A2: Yes, the module supports hot-swapping, allowing it to be replaced without system shutdown, ensuring minimal disruption.

Q3: Is the 3603T compliant with safety standards?

A3: Absolutely. It is certified for SIL 3 and SIL 4 safety applications in accordance with IEC 61508 standards.

Q4: Which chassis is required for installing the 3603T?

A4: The module must be installed in a Triconex 8110 chassis or compatible mainframe designed for Tricon system components.

Q5: How does the 3603T contribute to system reliability?

A5: It operates within a TMR architecture, allowing continuous control even if one of the processors fails, enhancing system fault tolerance.

Q6: What industries benefit the most from using Triconex 3603T?

A6: Industries such as oil & gas, petrochemical, power generation, pharmaceuticals, and nuclear energy benefit due to its high reliability, safety, and diagnostic capabilities.

Triconex 3603T Digital Output Modules

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

![]()

![]()

![]()

![]()