| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

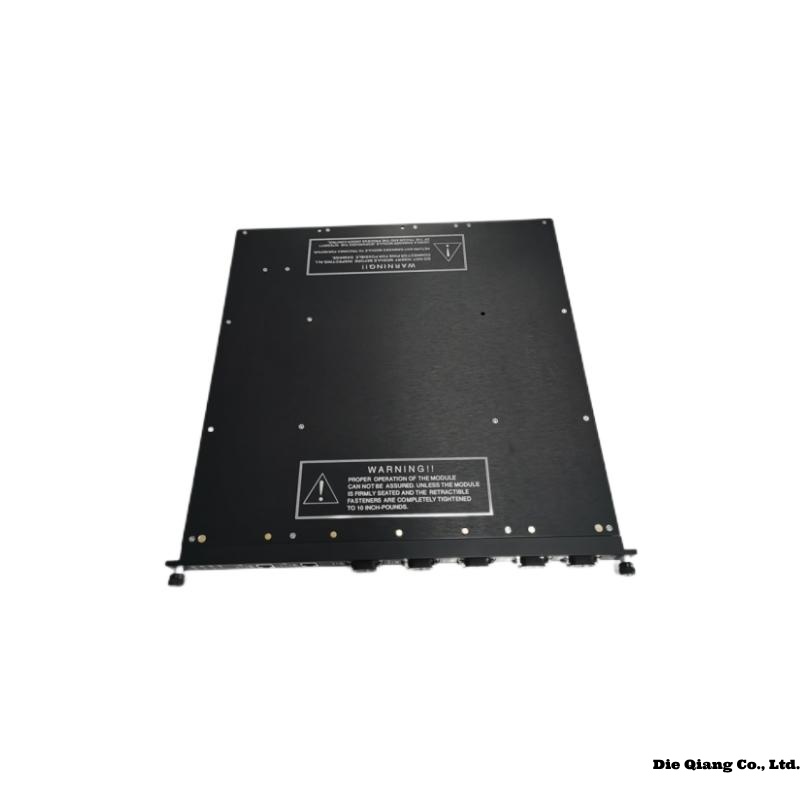

Product Introduction – Triconex 3604

The Triconex 3604 is a key component of the Triconex safety and critical control system, designed to deliver unmatched reliability in high-demand industrial environments. As part of the Triconex triple modular redundant (TMR) system architecture, the 3604 module plays a crucial role in processing discrete input signals, ensuring accurate data acquisition and robust fail-safe operations.

Triconex systems are widely recognized for their role in functional safety applications, including Emergency Shutdown Systems (ESD), Burner Management Systems (BMS), Fire and Gas Systems (F&G), and Turbomachinery Control. The 3604 module is engineered for long-term use in mission-critical environments where downtime and errors are not an option.

Product Advantages

-

Triple Modular Redundancy (TMR): Utilizes three independent and isolated channels to ensure fault tolerance and high availability.

-

High Diagnostic Coverage: Provides extensive self-diagnostics and built-in testing to monitor system health in real time.

-

Hot-Swappable Design: Enables replacement or maintenance without interrupting the operation of the overall system.

-

Robust Construction: Designed for harsh environments with extended temperature ranges and high resistance to EMI/RFI.

-

Certified Safety Compliance: Meets industry standards for functional safety such as IEC 61508 SIL 3 and ISA 84.01.

-

Long Product Lifecycle: Ensures availability and support over extended project durations, minimizing obsolescence risks.

Technical Specifications

| Parameter | Specification |

|---|---|

| Module Type | Digital Input Module (TMR) |

| Model Number | 3604 |

| System Compatibility | Triconex TMR Safety System |

| Input Voltage Range | 0–32 VDC |

| Input Type | Dry contact / Wet contact configurable |

| Number of Channels | 32 discrete input channels |

| Redundancy | Triple Modular Redundancy (TMR) |

| Diagnostic Function | Yes, channel-level diagnostics |

| Response Time | < 5 ms |

| Mounting Type | DIN Rail / Rack-mounted |

| Communication Interface | Backplane bus (Tricon system backplane) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 270 x 100 x 40 mm |

| Weight | 0.249 kg |

| Power Supply Voltage | 5 VDC (from backplane) |

| Certification | CE, CSA, ATEX, IEC 61508 SIL3, TÜV |

Product Applications

The Triconex 3604 is used across a wide array of industries and applications, including:

-

Oil and Gas: Emergency shutdown and wellhead control systems.

-

Petrochemical Plants: Reactor and process safety shutdown systems.

-

Power Generation: Turbine safety, balance of plant, and fire protection.

-

Chemical Processing: High-integrity pressure protection systems (HIPPS).

-

Pharmaceutical Industry: Batch process safety interlocks.

-

Water Treatment Facilities: Redundant input monitoring for critical water processes.

Compatible and Associated Models

The Triconex 3604 module is compatible with the following models and system components:

-

Triconex 3008 – Main Processor Module

-

Triconex 3625 – Digital Output Module

-

Triconex 3503E – Main Chassis

-

Triconex 8312 – Power Supply

-

Triconex 3700A – Analog Input Module

-

Triconex 3805E – Communication Module

These components work together to form a fully redundant, high-integrity control system designed for the most critical applications.

Installation Instructions

-

Preparation:

-

Ensure the system is powered down or the module slot is set to hot-swap mode.

-

Confirm that you are using an ESD-safe workstation.

-

-

Mounting the Module:

-

Align the Triconex 3604 module with the designated chassis slot.

-

Insert firmly until the connector mates securely with the backplane.

-

-

Securing the Module:

-

Use the chassis latches or screws to secure the module in place.

-

Verify alignment to avoid pin damage.

-

-

Configuration:

-

Configure the input channel types via system software (contact/wet).

-

Run initial diagnostics to confirm proper installation.

-

-

Power-Up and Testing:

-

Power the system.

-

Monitor diagnostics and LED indicators for module health status.

-

Perform I/O loop checks as necessary.

-

-

Documentation:

-

Log installation date, module serial number, and firmware revision.

-

6 Related Models in the Triconex Series

| Model | Type | Channels | Voltage | Dimensions (mm) | Weight | Description |

|---|---|---|---|---|---|---|

| Triconex 3601 | Digital Input Module | 16 | 24 VDC | 245 x 110 x 35 | 0.60 kg | TMR discrete input, high-speed logic detection |

| Triconex 3625 | Digital Output Module | 32 | 24 VDC | 245 x 110 x 35 | 0.65 kg | High-performance output with fail-safe control |

| Triconex 3700A | Analog Input Module | 16 | 0–10V / 4–20mA | 245 x 110 x 35 | 0.70 kg | Isolated analog input module with TMR design |

| Triconex 3721 | Analog Output Module | 8 | 4–20mA | 245 x 110 x 35 | 0.68 kg | Analog output module for precision applications |

| Triconex 3805E | Comm Module | N/A | N/A | 245 x 110 x 35 | 0.72 kg | Ethernet/IP communication interface |

| Triconex 8110 | Power Supply | N/A | 120/240 VAC | 260 x 115 x 40 | 1.20 kg | Redundant power unit for TMR systems |

8 Popular Triconex Models with Specifications

| Model | Type | Channels | Voltage | Dimensions (mm) | Weight | Description |

|---|---|---|---|---|---|---|

| Triconex 3008 | Main Processor | N/A | 5 VDC | 245 x 110 x 35 | 0.80 kg | Central processor module with TMR architecture |

| Triconex 3503E | Main Chassis | N/A | 5 VDC | 480 x 200 x 160 | 3.50 kg | Backplane chassis for housing Tricon modules |

| Triconex 3625 | Digital Output | 32 | 24 VDC | 245 x 110 x 35 | 0.65 kg | TMR output module for logic operations |

| Triconex 3700A | Analog Input | 16 | 0–10V / 4–20mA | 245 x 110 x 35 | 0.70 kg | Precision analog monitoring module |

| Triconex 3721 | Analog Output | 8 | 4–20mA | 245 x 110 x 35 | 0.68 kg | Reliable analog signal output |

| Triconex 3805E | Communication Module | N/A | N/A | 245 x 110 x 35 | 0.72 kg | Data interface module for network integration |

| Triconex 8110 | Power Supply | N/A | 120/240 VAC | 260 x 115 x 40 | 1.20 kg | System power supply with diagnostics |

| Triconex 9853-610 | Chassis Assembly | N/A | N/A | 500 x 210 x 160 | 3.80 kg | Mounting assembly for multiple modules |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Triconex 3604 module?

A1: The Triconex 3604 is a digital input module used to monitor and process discrete signals in safety-critical industrial control systems. It plays a key role in fault-tolerant input acquisition in a TMR environment.

Q2: Is the Triconex 3604 hot-swappable?

A2: Yes, the 3604 module is designed to be hot-swappable, allowing maintenance or replacement without interrupting system operation.

Q3: What certifications does the 3604 module carry?

A3: It is certified for use in SIL 3 applications per IEC 61508 and carries CE, CSA, ATEX, and TÜV certifications.

Q4: Can the 3604 module be configured for both dry and wet contacts?

A4: Yes, the input channels on the 3604 can be configured through software to accommodate both dry contact and wet contact signal types.

Q5: What type of systems use the Triconex 3604?

A5: It is commonly used in emergency shutdown systems, burner management systems, fire and gas detection, turbine control, and other safety instrumented functions.

Q6: What are the dimensions and weight of the 3604 module?

A6: The dimensions are 245 mm x 110 mm x 35 mm, and the weight is approximately 0.65 kg.

Triconex 3604 Digital Output Modules

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

![]()

![]()

![]()

![]()