| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

📘 Product Introduction

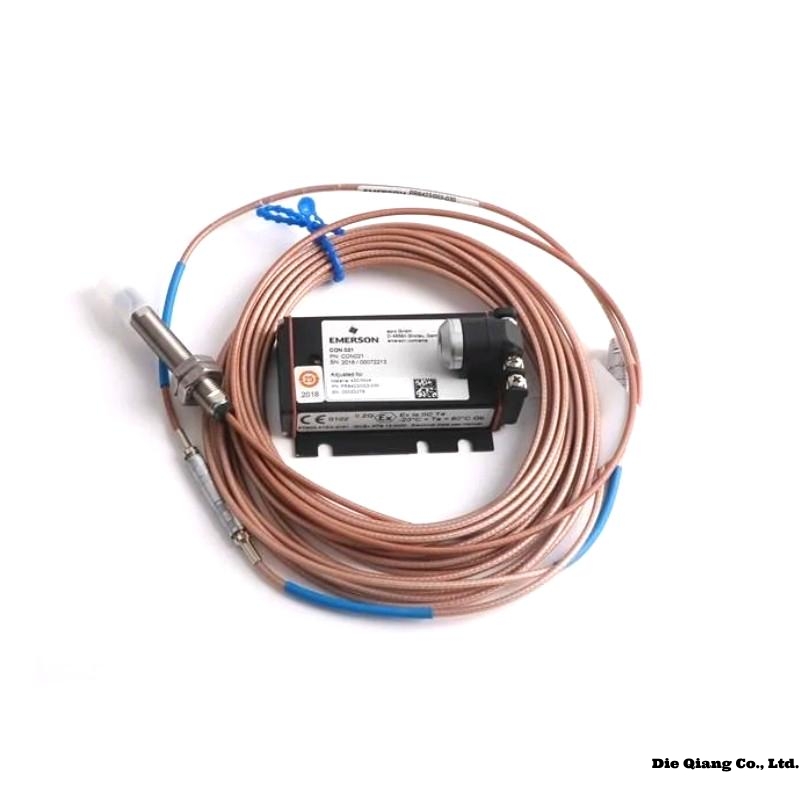

The Epro PR6423/000-140 is a high-performance eddy current proximity sensor developed by Epro, a brand under the Meggitt group. It is engineered to provide accurate and reliable non-contact measurements of shaft displacement, eccentricity, and vibration in rotating machinery. This sensor is commonly paired with the Epro MMR or MMS6000 series monitoring systems, forming a comprehensive solution for condition monitoring and predictive maintenance.

Designed for demanding industrial environments, the PR6423/000-140 is ideal for use in turbines, compressors, pumps, and other rotating equipment. It uses eddy current technology to detect minute displacements with high precision, contributing significantly to machinery safety and performance.

This sensor features robust construction, excellent temperature stability, and is available in a range of probe lengths and connector types, making it adaptable to various installation requirements.

✅ Product Advantages

-

High Precision: Offers extremely accurate non-contact measurements of shaft displacement and vibration.

-

Rugged Construction: Built with corrosion-resistant materials suitable for use in harsh industrial conditions, including high temperatures and hazardous zones.

-

Wide Compatibility: Seamlessly integrates with Epro’s MMR and MMS6000 series systems, and can also be configured with other monitoring devices.

-

Temperature Resilience: Capable of operating in high-temperature environments without degradation in performance.

-

Customizable Lengths: Available in various probe lengths to suit different installation configurations.

-

Long-Term Stability: Engineered for minimal signal drift over time, ensuring consistency in long-term monitoring applications.

📐 Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6423/000-140 |

| Measurement Principle | Eddy current, non-contact displacement measurement |

| Measuring Range | 0 – 2 mm (typical), depending on the configuration |

| Linearity | ≤ ±1% of Full Scale |

| Output Signal | Analog, proportional to displacement |

| Operating Temperature | -35°C to +180°C |

| Probe Tip Material | Stainless Steel |

| Housing Material | Stainless Steel |

| Thread Type | M14 x 1.5 (standard), others available on request |

| Supply Voltage | 24 VDC (typically via monitoring system) |

| Connector Type | MIL-C-5015 or customized |

| Protection Class | IP65 or higher |

| Weight | 0.1 kg |

| Probe diameter | 8 mm |

🛠️ Product Applications

The Epro PR6423/000-140 proximity sensor is widely used in industries such as:

-

Power Generation – Monitoring turbine shaft displacement and rotor vibration

-

Petrochemical Plants – Compressor condition monitoring

-

Oil & Gas – Measurement in high-temperature pump and motor applications

-

Steel and Paper Industries – Rotating equipment diagnostics

-

Marine Engineering – Monitoring propulsion and shafting systems

-

Manufacturing – Integration in predictive maintenance systems for rotating assets

🔗 Compatible Models / Systems

The PR6423/000-140 sensor is designed for compatibility with:

-

Epro CON021 / CON041 converter modules

-

Epro MMS6220 monitoring module

-

Epro MMS6000 Series vibration monitoring systems

-

Epro MMR 131 / MMR 135 rack-based condition monitoring units

-

BN3300 / BN3500 systems (via adapter)

-

Other eddy current monitoring systems with matching input ranges

🧰 Installation Instructions

-

Probe Mounting:

-

Install the probe perpendicular to the target shaft surface.

-

Use mounting brackets or holders as specified by Epro.

-

Ensure a secure mechanical connection to avoid vibration-induced errors.

-

-

Gap Adjustment:

-

Set the sensor-to-target gap according to the datasheet (typically 1 mm).

-

Use a feeler gauge for accurate setting.

-

-

Cable Connection:

-

Connect the sensor to the CON021 or CON041 converter using shielded cables.

-

Ensure grounding is properly implemented to reduce electrical noise.

-

-

Converter Setup:

-

Mount the converter in a protected enclosure.

-

Connect converter output to the MMS monitoring system or a data acquisition unit.

-

-

System Calibration:

-

Use the system’s calibration tools or software to ensure accurate readings.

-

Validate calibration against mechanical references.

-

-

Verification:

-

Perform signal checks after installation to confirm proper functionality.

-

Conduct routine checks during machine operation for system health.

-

🔄 6 Related Models (Same Series or Similar)

| Model Number | Measuring Range | Temp Range | Probe Thread | Length Options | Connector Type |

|---|---|---|---|---|---|

| PR6423/002-000 | 0 – 2 mm | -35°C to +180°C | M14 x 1.5 | 50 / 100 / 150mm | MIL-C-5015 |

| PR6423/003-031 | 0 – 4 mm | -35°C to +180°C | M16 x 1.5 | Customizable | Radial MIL |

| PR6423/005-000 | 0 – 8 mm | -35°C to +200°C | M20 x 1.5 | 100 / 150 / 200mm | Axial MIL |

| PR6423/010-010 | 0 – 2 mm | -35°C to +120°C | UNF 3/8-24 | 100 mm | Miniature MIL |

| PR6423/000-030 | 0 – 2 mm | -35°C to +150°C | M14 x 1.5 | 80 mm | MIL Standard |

| PR6423/000-121 | 0 – 2 mm | -35°C to +180°C | M14 x 1.5 | 120 mm | Shielded coaxial |

⭐ 8 Popular Epro Models with Parameters

| Model Number | Type | Measuring Range | Temp Range | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|---|

| PR6423/000-140 | Proximity Probe | 0 – 2 mm | -35°C to +180°C | 24 VDC | 100 x 14 | 250g |

| CON021 | Signal Converter | N/A | -20°C to +70°C | 24 VDC | 110 x 35 x 25 | 150g |

| MMS6220 | Monitoring Module | N/A | 0°C to +60°C | 24 VDC | 150 x 120 x 40 | 500g |

| PR6424/010-100 | High Temp Probe | 0 – 2 mm | -35°C to +400°C | 24 VDC | 100 x 14 | 280g |

| CON041 | Signal Converter | N/A | -20°C to +85°C | 24 VDC | 110 x 40 x 30 | 170g |

| MMR 131 | Monitoring Rack Module | Multi-channel | 0°C to +60°C | 24 VDC | 190 x 120 x 300 | 2.5kg |

| PR6425/010-000 | Axial Vibration Probe | 0 – 4 mm | -35°C to +200°C | 24 VDC | 120 x 16 | 300g |

| MMS6110 | Signal Conditioning Module | N/A | 0°C to +60°C | 24 VDC | 130 x 110 x 35 | 450g |

❓ Frequently Asked Questions (FAQs)

Q1: What is the typical gap distance required for the PR6423/000-140?

A1: The recommended initial gap between the sensor and the target surface is approximately 1.0 mm. Exact gap should be confirmed with the system calibration tools for optimal accuracy.

Q2: Can this probe be used in hazardous environments?

A2: Yes, the PR6423/000-140 is constructed with stainless steel and can be installed in hazardous environments when used with certified protection systems and enclosures.

Q3: What converter modules are compatible with this probe?

A3: The PR6423/000-140 is compatible with CON021 and CON041 converter modules, which condition the sensor signal for input into monitoring systems like MMS6000 or MMR series.

Q4: How is the sensor connected to the monitoring system?

A4: The sensor connects to a converter (such as CON021) via a shielded cable, and the converter’s output is then wired to the monitoring system.

Q5: What is the life expectancy of this sensor?

A5: When installed and operated under recommended conditions, the PR6423/000-140 can function reliably for over 10 years, with minimal maintenance required.

Q6: Can this sensor be used with non-Epro monitoring systems?

A6: Yes, it can be integrated into third-party systems as long as they accept the appropriate signal conditioning and voltage range. Signal converters may be required for compatibility.

Epro PR6423/000-140 8mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||