| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

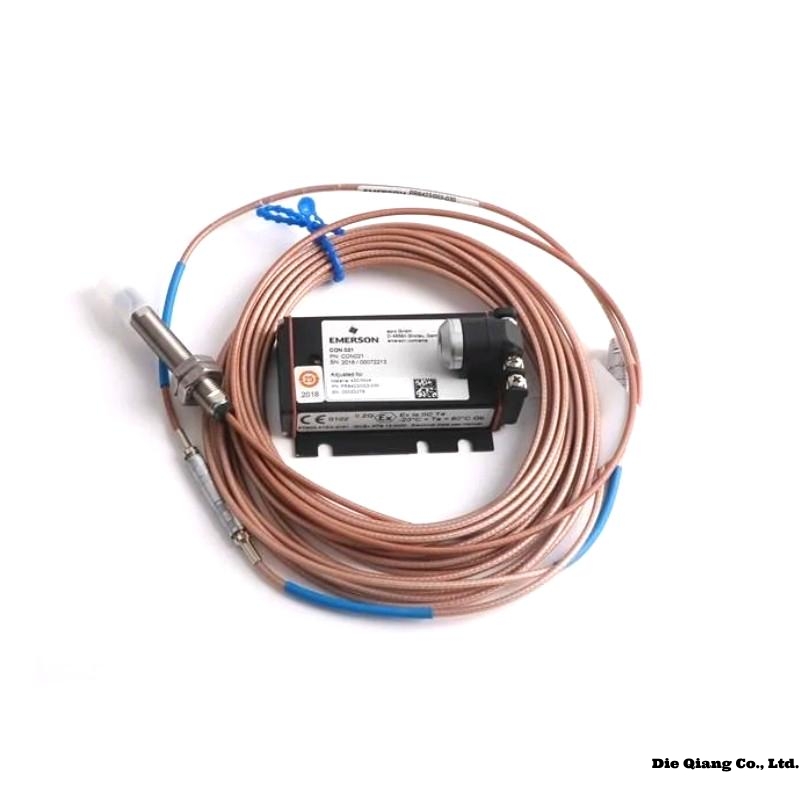

Epro PR6423/000-131 Detailed Product Information

Product Introduction

The Epro PR6423/000-131 is a high-precision eddy current sensor specifically engineered for continuous, non-contact displacement measurement. Designed for use in industrial monitoring systems, particularly those dealing with rotating machinery such as turbines, compressors, and pumps, it delivers outstanding performance even in harsh operating environments. The PR6423/000-131 is renowned for its robust construction, excellent temperature stability, and high signal fidelity, ensuring reliable and accurate vibration and position monitoring for critical assets. It integrates seamlessly with Epro’s MMS6000 and other standard monitoring systems, making it an essential component for predictive maintenance programs.

Product Advantages

-

High Accuracy: Provides precise and consistent displacement measurements even in extreme conditions.

-

Rugged Design: Encased in durable stainless steel housing suitable for aggressive industrial environments.

-

Wide Operating Range: Supports high-frequency vibration measurements over broad temperature and pressure ranges.

-

Easy Integration: Compatible with a wide range of monitoring and protection systems, including Epro’s MMS6000 series.

-

Long Service Life: Designed for long-term reliability with minimal maintenance requirements.

-

Customizable: Various cable lengths, connector types, and thread configurations are available for flexible installation.

Technical Specifications

| Specification | Details |

|---|---|

| Model | Epro PR6423/000-131 |

| Measurement Principle | Eddy Current Displacement Sensor |

| Frequency Range | 0 Hz to 10 kHz |

| Measuring Range | 0 to 2 mm (adjustable) |

| Sensitivity | 4 mV/μm (typical) |

| Linearity Error | ≤ 1% of Full Scale |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Material of Housing | Stainless Steel |

| Probe diameter | 8 mm |

| Weight | 0.1 kg |

| Supply Voltage | -24 VDC (via connecting cable from driver) |

| Output Signal | Voltage output proportional to displacement |

| Mounting Thread | M8 x 1.0 (standard) |

| Protection Class | IP68 (fully sealed) |

| Cable Type | Integrated armored cable |

| Cable Length | Typically 5 m, customizable |

| Certification | CE, ATEX for hazardous areas (on request) |

Applications

-

Turbomachinery Monitoring: Used in turbines, compressors, and expanders for shaft vibration and axial displacement monitoring.

-

Pumps and Fans: Continuous monitoring of bearing and shaft conditions to prevent unexpected failures.

-

Motors and Generators: Measurement of shaft movements for early fault detection.

-

Industrial Gearboxes: Ensures proper alignment and detects excessive vibrations or bearing wear.

-

Oil & Gas Industry: Deployed in refineries and pipelines for monitoring rotating equipment.

-

Energy Sector: Employed in wind turbines and power plants for predictive maintenance strategies.

Compatible Models

-

Epro CON011 (Proximity probe driver module)

-

Epro MMS6312 (Vibration Monitoring System)

-

Epro MMS6120 (Multichannel Monitoring System)

-

Epro PR6426 (High-temperature probe)

-

Epro PR6424 (Compact proximity probe)

-

Epro CON021 (New-generation proximity driver)

Installation Instructions

-

Preparation: Ensure the mounting area is clean and free from debris or contamination. Verify all accessories such as the driver and extension cables are ready for installation.

-

Probe Mounting: Thread the PR6423/000-131 probe into the designated mounting hole using the M8 x 1.0 standard thread. Tighten to the specified torque (usually 2-3 Nm) without damaging the sensor.

-

Gap Adjustment: Set the probe gap according to the required measuring range. Typically, a gap of 1.0 mm is recommended for best performance.

-

Cable Routing: Secure the armored cable carefully to avoid mechanical stress and ensure electromagnetic interference is minimized.

-

Connection: Connect the sensor to the CON011 driver module, observing the correct wiring according to the provided datasheet.

-

Verification: After installation, check the sensor’s output at zero displacement and full-scale deflection to ensure correct setup.

-

Final Steps: Record initial settings and gap measurements for future reference and maintenance.

Related Models (Epro Series)

| Model Number | Measuring Range | Operating Temp | Thread Size | Weight |

|---|---|---|---|---|

| PR6423/000-030 | 0 – 2 mm | -35°C to +180°C | M8 x 1.0 | 120 g |

| PR6423/000-040 | 0 – 2 mm | -35°C to +180°C | M8 x 1.0 | 118 g |

| PR6423/000-050 | 0 – 2 mm | -35°C to +180°C | M8 x 1.0 | 122 g |

| PR6424/000-031 | 0 – 4 mm | -35°C to +180°C | M10 x 1.0 | 150 g |

| PR6426/000-010 | 0 – 2 mm | -35°C to +400°C | M8 x 1.0 | 135 g |

| PR6425/010-010 | 0 – 8 mm | -35°C to +180°C | M14 x 1.5 | 200 g |

Popular Epro Models

| Model Number | Application | Frequency Range | Dimensions | Weight |

|---|---|---|---|---|

| PR6423/000-131 | Shaft displacement measurement | 0 Hz – 10 kHz | Ø8 mm x 50 mm | 120 g |

| PR6424/000-030 | Vibration monitoring | 0 Hz – 8 kHz | Ø10 mm x 45 mm | 140 g |

| PR6426/010-010 | High-temperature applications | 0 Hz – 6 kHz | Ø8 mm x 55 mm | 135 g |

| CON011 | Proximity probe driver | – | 90 x 35 x 110 mm | 500 g |

| MMS6312 | Machine monitoring system | – | 483 x 132 x 222 mm | 6.5 kg |

| MMS6120 | Multichannel vibration monitoring | – | 483 x 132 x 250 mm | 7.0 kg |

| PR6425/010-010 | Axial position measurement | 0 Hz – 5 kHz | Ø14 mm x 60 mm | 200 g |

| CON021 | Advanced proximity probe driver | – | 90 x 35 x 110 mm | 520 g |

FAQ (Frequently Asked Questions)

Q1: What is the measuring range of the Epro PR6423/000-131 sensor?

A1: The measuring range is typically 0 to 2 mm, and it can be adjusted during installation to suit the application.

Q2: Can the PR6423/000-131 be used in hazardous environments?

A2: Yes, it can be provided with ATEX certification upon request for use in explosive or hazardous areas.

Q3: What monitoring system is the PR6423/000-131 compatible with?

A3: It is fully compatible with the Epro MMS6000 system and other standard vibration monitoring equipment.

Q4: What is the supply voltage requirement for the PR6423/000-131?

A4: The sensor operates with a -24 VDC supply voltage provided through its connecting cable from the driver unit.

Q5: What is the protection rating of the Epro PR6423/000-131?

A5: It features an IP68 protection class, making it dust-tight and suitable for continuous immersion in water.

Q6: How should I adjust the gap of the PR6423/000-131 sensor during installation?

A6: Use a feeler gauge to set the gap, typically around 1.0 mm, and verify the setting by checking the zero-displacement output signal.

Epro PR6423/000-131 8mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||