| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

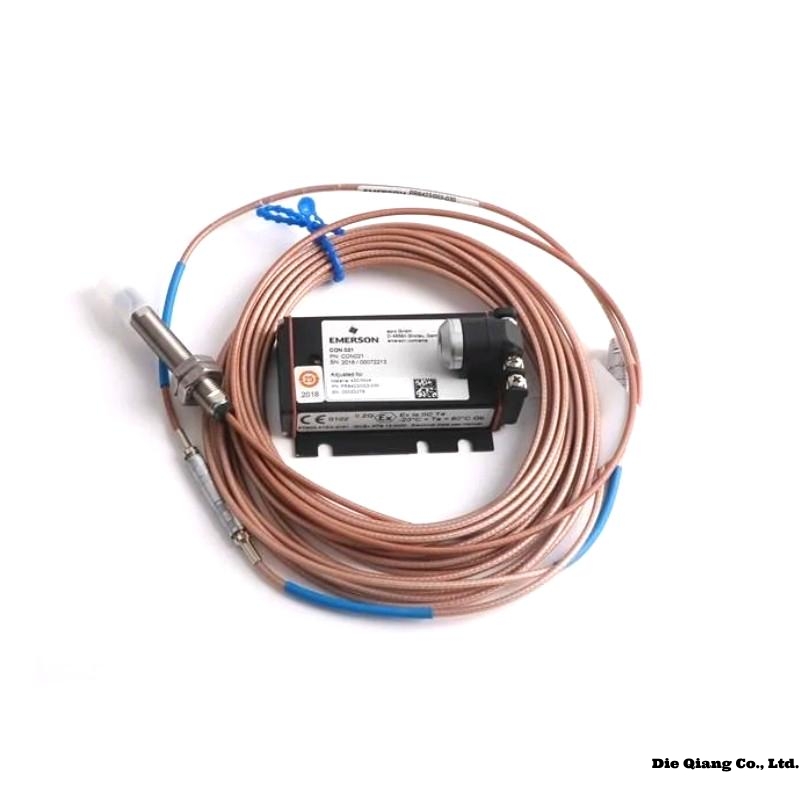

Product Overview: Epro PR6423/000-000+CON011

The Epro PR6423/000-000+CON011 is a premium-quality eddy current proximity sensor designed for continuous, precise, and reliable monitoring of critical rotating machinery. Developed by Epro, a respected brand under Brüel & Kjær Vibro, this sensor-transducer combination is part of the PR6423 series and is primarily used for non-contact displacement measurement.

The sensor is widely implemented in condition monitoring systems, especially in turbines, compressors, pumps, and other rotating equipment. It plays a key role in detecting shaft vibrations and axial displacement, contributing significantly to predictive maintenance strategies in industrial environments.

The sensor (PR6423) and converter (CON011) are engineered to provide a high level of accuracy and resistance to environmental interferences such as temperature fluctuations, electromagnetic interference, and vibration, ensuring consistent and long-term operation.

Product Advantages

-

High Precision: Offers exceptional measurement accuracy for displacement and vibration signals even in harsh industrial conditions.

-

Non-Contact Measurement: Ensures zero mechanical wear, reducing maintenance requirements and extending product lifespan.

-

High Reliability: Built to operate in extreme temperatures and industrial environments with high resistance to contamination and EMI.

-

Versatile Application: Compatible with multiple machine types, including turbines, pumps, motors, and compressors.

-

Modular Design: The sensor and converter can be easily integrated into different configurations for various monitoring systems.

-

Brand Trust: Manufactured by Epro, known for robust design and high-performance condition monitoring solutions.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6423/000-000+CON011 |

| Sensor Type | Eddy Current Proximity Sensor |

| Measuring Range | 0 to 2 mm |

| Frequency Response | 0 to 10 kHz |

| Output Signal | Voltage (mV) proportional to gap/displacement |

| Power Supply | ±15 V DC via CON011 |

| Operating Temperature | -35°C to +180°C (Sensor), -25°C to +85°C (Converter) |

| Housing Material | Stainless Steel |

| Protection Class | IP65 |

| Mounting Thread | M14x1.5 (custom variants available) |

| Sensor Dimensions | Ø 14 mm x 80 mm |

| Probe diameter | 8 mm |

| Weight | 0.7 kg |

| Voltage Sensitivity | Typically 7.87 mV/µm |

Applications

-

Steam and Gas Turbines: Monitoring shaft axial and radial displacement to avoid critical failures.

-

Compressors: Detecting early signs of imbalance, misalignment, and bearing wear.

-

Pumps: Measuring vibration and displacement for continuous operation and damage prevention.

-

Motors and Generators: Ensuring reliable monitoring of shaft movements for predictive maintenance.

-

Gearboxes: Providing critical data on rotational components to reduce mechanical failure.

-

Industrial Fans: Monitoring blade vibration and shaft position for optimal performance.

Compatible Models and Systems

The PR6423/000-000+CON011 sensor set is compatible with a wide range of Epro and B&K Vibro systems including:

-

Epro MMS 6000

-

Epro MMS 8000

-

Brüel & Kjær Vibro VIBROCONTROL 6000 (VC-6000)

-

Epro CON021 Converter

-

Epro CON031 Converter

-

Monitoring systems with standard voltage input modules (±10 V)

-

Systems with BNC or terminal block interfaces

Installation Instructions

-

Preparation:

-

Verify that the installation area is clean and free from metal particles or dust.

-

Confirm that the sensor thread (e.g., M14x1.5) matches the machine’s probe port.

-

-

Mounting the Sensor:

-

Carefully screw the PR6423 sensor into the mounting hole until the specified distance from the shaft is achieved.

-

Use a feeler gauge to adjust the gap between the sensor tip and the shaft. The typical initial gap is 1 mm (±0.1 mm).

-

-

Cable Connection:

-

Connect the sensor cable to the CON011 converter.

-

Ensure secure connections to prevent signal loss or electromagnetic interference.

-

-

Converter Setup:

-

Mount the CON011 converter in a control cabinet or junction box.

-

Provide power supply of ±15V DC.

-

Connect the output terminals to the data acquisition or control system.

-

-

Testing and Calibration:

-

Power the system and check signal integrity.

-

Adjust zero and span settings if required.

-

Validate system functionality using a test signal or reference movement.

-

-

Maintenance:

-

Periodically inspect the sensor for contamination or mechanical damage.

-

Verify connector integrity and cable insulation.

-

Related Models (Same Series or Compatible)

| Model | Description | Measurement Range | Temp Range | Thread Size |

|---|---|---|---|---|

| PR6423/10R-000 | High-temp proximity sensor | 0–2 mm | -35°C to +180°C | M14x1.5 |

| PR6423/002-000 | General-purpose proximity sensor | 0–2 mm | -35°C to +150°C | M10x1 |

| PR6423/003-000 | Compact version for tight spaces | 0–2 mm | -35°C to +180°C | M8x1 |

| PR6424/000-010 | Extended-range sensor | 0–4 mm | -35°C to +180°C | M14x1.5 |

| CON021 | Enhanced converter for PR642x sensors | – | -25°C to +85°C | DIN Rail Mount |

| CON031 | Advanced converter with diagnostics | – | -25°C to +85°C | Panel Mount |

Popular Models from Epro (with Specifications)

| Model | Description | Measuring Range | Temp Range | Dimensions | Weight | Voltage |

|---|---|---|---|---|---|---|

| PR6423/000-000+CON011 | Standard eddy current sensor kit | 0–2 mm | -35°C to +180°C | Ø14 x 80 mm / 80x50x25 mm | ~450 g | ±15 V DC |

| PR6423/10R-000+CON021 | High-temp probe with converter | 0–2 mm | -35°C to +180°C | Same as above | ~460 g | ±15 V DC |

| PR6424/000-010+CON031 | Extended gap sensor system | 0–4 mm | -35°C to +180°C | Ø14 x 90 mm / 90x60x30 mm | ~470 g | ±15 V DC |

| CON021 | Signal converter (DIN rail mount) | – | -25°C to +85°C | 110 x 75 x 25 mm | ~300 g | ±15 V DC |

| CON031 | Digital diagnostics converter | – | -25°C to +85°C | 120 x 80 x 30 mm | ~320 g | ±15 V DC |

| PR9268/201-000 | Speed sensor for rotating machinery | 0–10000 RPM | -40°C to +125°C | Ø18 x 70 mm | ~280 g | 24 V DC |

| MMS3120 | Vibration monitor module | – | 0°C to +60°C | 130 x 100 x 35 mm | ~600 g | 24 V DC |

| MMS6110 | Signal processing unit | – | 0°C to +50°C | 140 x 120 x 40 mm | ~700 g | 24 V DC |

Frequently Asked Questions (FAQ)

Q1: What is the function of the PR6423/000-000 sensor?

A1: The PR6423/000-000 is a non-contact eddy current sensor used to measure the displacement or vibration of rotating machinery components such as shafts and rotors.

<br>

Q2: Can the PR6423 series be used in high-temperature environments?

A2: Yes, certain variants like PR6423/10R-000 are designed to withstand temperatures up to +180°C, making them suitable for high-temperature applications like turbines.

<br>

Q3: Is the CON011 converter mandatory for operation?

A3: Yes, the CON011 converter is specifically matched to the PR6423 sensor and is essential for signal conditioning and proper voltage output to the monitoring system.

<br>

Q4: How do I ensure the correct installation gap for the sensor?

A4: Use a feeler gauge to set the initial air gap, typically 1.0 mm, and fine-tune it based on calibration data or shaft material.

<br>

Q5: What kind of monitoring systems is this product compatible with?

A5: It is compatible with Epro’s MMS6000 and MMS8000 systems, Brüel & Kjær Vibro systems, and any third-party condition monitoring system accepting ±10V analog input.

<br>

Q6: How often should the sensor be maintained or recalibrated?

A6: Maintenance intervals depend on environmental conditions, but visual inspection and functional testing every 6 to 12 months are recommended.

Epro PR6423/000-000+CON011 8mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||