| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

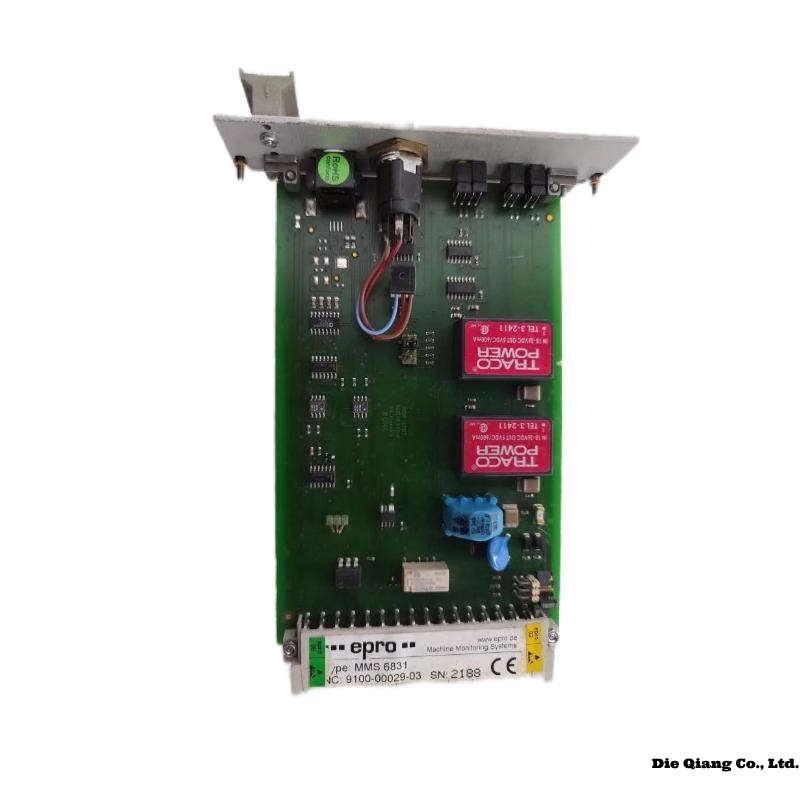

Epro MMS6831 9100-00029-03 – Comprehensive Product Overview

Product Introduction

The Epro MMS6831 9100-00029-03 is a highly precise signal conditioning module specifically designed for use in critical industrial machinery monitoring and protection systems. Engineered by Epro, a well-established brand in vibration and condition monitoring, the MMS6831 forms a core component within Epro’s renowned MMS6000 series.

This device processes sensor signals—particularly from proximity probes and velocity sensors—into standardized outputs for analysis, diagnostics, and alarm triggering. Designed with high reliability, electromagnetic immunity, and operational stability in mind, the MMS6831 is ideal for integration into centralized monitoring racks in turbines, compressors, pumps, and other rotating equipment.

The 9100-00029-03 variant represents a specific configuration with enhanced compatibility for European and Asian industrial standards, ensuring wide applicability across international markets.

Product Advantages

-

High Signal Accuracy: Converts raw signals from sensors into accurate, standardized outputs for precise monitoring.

-

Excellent Stability: Offers reliable long-term performance with low drift in output values, ensuring consistent diagnostics.

-

Modular Design: Designed for seamless integration into the MMS6000 rack system, allowing scalability and flexible system architecture.

-

High Electromagnetic Immunity: Functions reliably in high-noise environments typical of heavy industrial facilities.

-

Robust Construction: Built with industrial-grade components to withstand harsh operational environments including high temperature and vibration.

-

International Compatibility: Compliant with global industrial standards, suitable for deployment across different regional facilities.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | MMS6831 9100-00029-03 |

| Power Supply Voltage | 24 V DC (nominal), range: 18–30 V DC |

| Input Type | Proximity probe, velocity sensor |

| Signal Output | 4–20 mA / ±5 V or configurable analog output |

| Frequency Range | 0.1 Hz – 10 kHz |

| Dimensions | 300 x 200 x 250 mm |

| Weight | 3 kg |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | Plug-in for MMS6000 rack system |

| EMC Compliance | EN 61000-6-2 / EN 61000-6-4 |

| Protection Class | IP20 (installed), per IEC 60529 |

| Response Time | <10 ms |

| Output Load | 500 Ω max at 20 mA output |

| Galvanic Isolation | Yes, input to output |

Applications

-

Turbine Vibration Monitoring

Ideal for gas and steam turbines, offering precise signal processing for protection systems. -

Compressor Health Diagnostics

Accurately detects vibration patterns to prevent critical compressor failures. -

Industrial Pump Systems

Monitors vibration anomalies caused by misalignment, cavitation, or bearing wear. -

Generator Condition Monitoring

Ensures early detection of rotor imbalance or shaft misalignment in generators. -

Centrifugal Fans & Blowers

Utilized in HVAC and processing systems for preventive maintenance. -

Refineries & Petrochemical Plants

Applied extensively in hazardous process environments due to its EMI immunity.

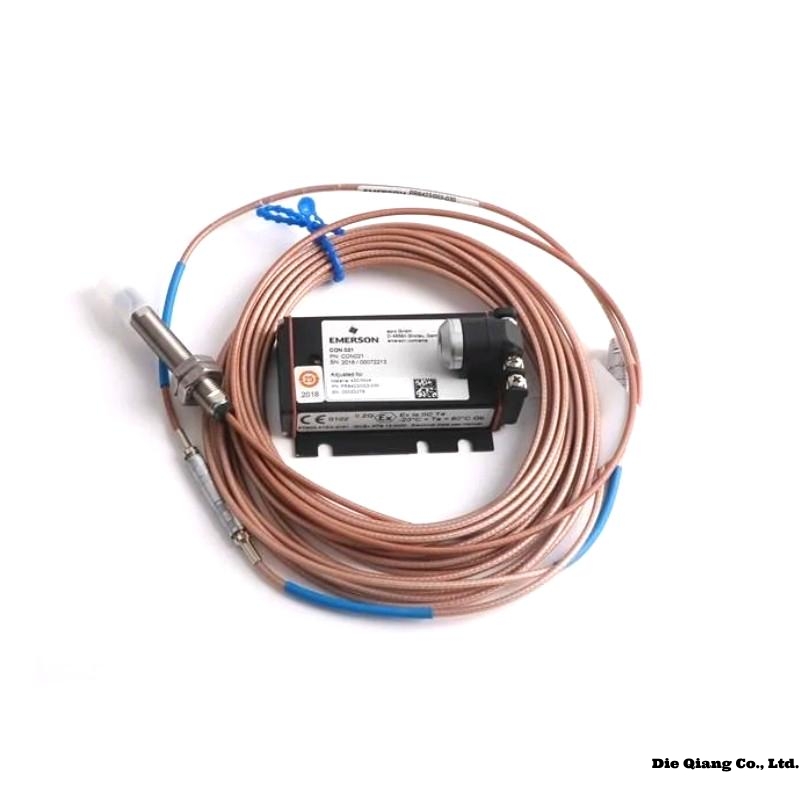

Compatible Models for Integration

-

Epro PR9268 – Eddy current proximity probe for vibration measurement

-

Epro PR9376 – Velocity sensor for machinery casing vibrations

-

Epro MMX672 – Multi-channel condition monitoring module

-

Epro MMS6110 – Signal conditioning rack compatible with MMS6000 modules

-

Epro CON011 – Proximity system connection module

-

Epro MMS6210 – Power supply module for MMS6000 series

Installation Instructions

-

Pre-Installation Check: Ensure the MMS6000 rack is powered off and grounded. Verify compatibility with the connected sensor type and signal range.

-

Module Insertion: Insert the MMS6831 into the designated slot in the MMS6000 rack. It should slide smoothly and latch firmly into place.

-

Wiring: Connect the sensor leads to the designated terminal block on the module. Ensure polarity and shielding are correctly implemented to avoid interference.

-

Power Connection: Connect the 24V DC power source via the rack’s common power line.

-

Signal Output Configuration: Using DIP switches or software (depending on revision), configure the output range (e.g., 4–20 mA or ±5 V).

-

System Integration Test: Power on the system and validate the signal output using a calibrated testing device or DCS/PLC interface.

-

Final Commissioning: Run initial diagnostics using the Epro monitoring software or relevant HMI for proper vibration signal capture.

6 Related Models in the MMS6000 Series

| Model | Function | Input Type | Output Type | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|---|

| MMS6110 | Signal conditioning rack | Module carrier | – | – | 483 x 133 x 300 | 3.2 kg |

| MMS6220 | Dual channel vibration processing | Proximity, Velocity | 4–20 mA / ±5 V | 24 V DC | 24 x 100 x 125 | 260 g |

| MMS6210 | Power supply module | – | Power distribution | 24 V DC | 48 x 100 x 125 | 290 g |

| MMS6250 | Process signal interface module | Analog process signals | 0–10 V / 4–20 mA | 24 V DC | 24 x 100 x 125 | 265 g |

| MMS6822 | Signal converter for velocity probes | Velocity sensor | Analog output | 24 V DC | 24 x 100 x 125 | 255 g |

| MMS6841 | Speed monitoring module | Magnetic pickup | Relay / Analog | 24 V DC | 24 x 100 x 125 | 270 g |

8 Popular Epro Models with Technical Specifications

| Model | Function | Input Type | Output Type | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|---|

| PR9268 | Eddy current proximity sensor | Shaft displacement | Raw voltage | Powered by MMS | 12 x 60 (probe only) | 80 g |

| PR9376 | Velocity sensor | Vibration velocity | mV/g | Self-powered | 60 x 40 x 30 | 150 g |

| MMS6220 | Vibration module (2-channel) | Proximity, Velocity | 4–20 mA / ±5 V | 24 V DC | 24 x 100 x 125 | 260 g |

| MMS6841 | Speed monitoring module | Magnetic pickup | Relay / Analog | 24 V DC | 24 x 100 x 125 | 270 g |

| CON011 | Terminal connection block | Proximity system cable | – | – | 80 x 60 x 35 | 120 g |

| MMS6110 | Main rack for signal modules | – | – | 24 V DC | 483 x 133 x 300 | 3.2 kg |

| MMX672 | Multichannel vibration analysis | Mixed signal input | Digital | 24 V DC | 100 x 150 x 180 | 1.1 kg |

| MMS6250 | Analog signal conditioner | Process signals | 4–20 mA | 24 V DC | 24 x 100 x 125 | 265 g |

FAQs (Q&A Format)

Q1: What type of sensors can be connected to the MMS6831 module?

A1: The MMS6831 is designed to interface with eddy current proximity probes and velocity sensors commonly used for vibration monitoring in rotating machinery.

Q2: Is the MMS6831 hot-swappable within the MMS6000 rack system?

A2: No, the module should only be inserted or removed when the rack is powered down to avoid electrical or signal errors.

Q3: What kind of output does the MMS6831 provide?

A3: It provides configurable analog outputs such as 4–20 mA or ±5 V, depending on the system requirements.

Q4: Can the MMS6831 be used in hazardous environments?

A4: While the module is robust and offers good EMI resistance, it should be installed in a certified enclosure if used in hazardous areas.

Q5: How can the module be tested after installation?

A5: Output signals can be tested using a signal calibrator, loop tester, or through digital diagnostic tools connected to the system PLC or DCS.

Q6: What maintenance does the MMS6831 require?

A6: Minimal maintenance is needed. Periodic inspection for connection integrity and module cleanliness is sufficient for long-term performance.

Epro MMS6831 9100-00029-03 Interface Cards

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||