| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Epro MMS6822 – Detailed Product Overview

Product Introduction

The Epro MMS6822 is a high-performance dual-channel signal conditioning module designed for industrial condition monitoring systems. Engineered for use in critical rotating machinery, it converts signals from eddy current proximity sensors into standard output values representing vibration, axial displacement, or gap measurements. The MMS6822 offers reliable real-time data acquisition, vital for predictive maintenance and fault prevention strategies across a wide range of industries, including oil & gas, power generation, chemical, and manufacturing.

The MMS6822 is part of Epro’s renowned MMS6000 series, known for its rugged construction, precise signal processing capabilities, and seamless integration with monitoring and protection systems. With its DIN rail mounting design and robust electrical shielding, it is built for demanding industrial environments.

Product Advantages

-

Dual Channel Design: Allows simultaneous processing of two sensor inputs, reducing space and cost.

-

High Signal Accuracy: Ensures minimal noise and drift for accurate vibration and displacement measurements.

-

Industrial-Grade Durability: Designed to withstand high temperatures, EMI, and mechanical stress common in industrial environments.

-

Wide Compatibility: Fully compatible with Epro’s PR642x sensor series and other standard proximity probes.

-

User-Configurable Parameters: Supports field programmability for sensitivity, alarm levels, and measurement ranges.

-

Modular Integration: Easily integrates into MMS6000 series racks or standalone applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | MMS6822 |

| Channels | 2 (independent signal processing channels) |

| Input | Eddy current proximity probes (e.g., PR6422, PR6423) |

| Output | ±10 V or 4–20 mA (configurable) |

| Measurement Range | 0–2 mm (gap), 0–1000 µm (vibration) |

| Frequency Response | 0.5 Hz to 10 kHz |

| Alarm Relays | 2 per channel (Alert and Danger) |

| Power Supply Voltage | 24 V DC (±10%) |

| Power Consumption | Max. 5 W |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | Up to 95%, non-condensing |

| Mounting | DIN Rail / Rack Mount |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.25 kg |

| Certification | CE, ATEX (on applicable configurations) |

Product Applications

-

Turbomachinery Monitoring: Turbines, compressors, and pumps in petrochemical and power plants.

-

Condition-Based Maintenance: Real-time condition data for predictive maintenance systems.

-

Axial Displacement Detection: Monitoring shaft axial position in rotating equipment.

-

Rotor Vibration Analysis: Precise vibration tracking to prevent mechanical failure.

-

Machine Protection Systems: Integration into Epro or third-party safety shutdown systems.

Compatible Models / Accessories

The MMS6822 is designed to work seamlessly with the following Epro and industry-standard components:

-

PR6422: Eddy current proximity probe for axial position.

-

PR6423: Proximity probe for radial vibration monitoring.

-

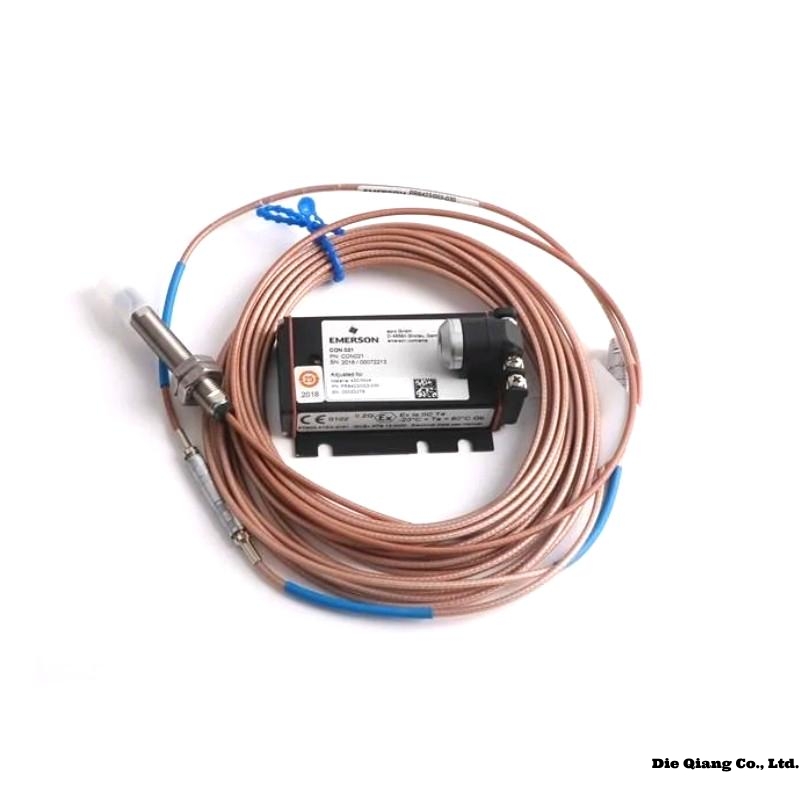

CON021/CON041: Matching pre-amplifier and sensor interface modules.

-

MMS6700 Rack: Modular rack system for multi-channel monitoring.

-

MMS6000 Series Modules: Including MMS6312, MMS6410 for extended monitoring functions.

Installation Instructions

-

Mounting: Install the MMS6822 module on a DIN rail or within an MMS6000-compatible rack. Ensure the module is securely fixed and positioned in a vibration-free environment if possible.

-

Power Connection: Supply 24 V DC using shielded power cables. Observe polarity to prevent damage.

-

Sensor Wiring: Connect PR642x sensors to the appropriate input terminals. Ensure cable shielding is grounded properly to avoid interference.

-

Output Configuration: Set the output type (Voltage/Current) via DIP switches or software (if applicable). Connect outputs to DCS, PLC, or protection relays.

-

Alarm Setup: Configure alert and danger alarm thresholds. Connect relay outputs to alarm systems or shutdown logic.

-

Commissioning: Verify signal levels with test equipment. Confirm calibration using a reference standard. Adjust sensitivity as needed.

-

Final Check: Confirm all connectors are tight, labels are correct, and module LED indicators show normal operation.

Related Models (Same Series or Functional Family)

| Model | Description | Measurement | Output | Mounting |

|---|---|---|---|---|

| MMS6810 | Single-channel version of MMS6822 | Vibration, Axial | ±10 V | DIN Rail |

| MMS6312 | 12-channel signal processing unit | Vibration, Displacement | 4–20 mA | Rack Mount |

| MMS6410 | Signal conditioner with relay logic | Protection Functions | Relay Output | Rack Mount |

| MMS6620 | Dual-channel module with extended frequency | High-Frequency Vibration | 4–20 mA | DIN Rail |

| MMS6700 | Rack for MMS6000 modules | Modular Slot System | N/A | Cabinet/Rack |

| MMS6830 | Dual-channel with diagnostic interface | Vibration Diagnostics | Digital Output | DIN Rail |

Popular Epro Models

| Model | Description | Voltage | Dimensions (mm) | Weight | Application |

|---|---|---|---|---|---|

| PR6422/10R-010 | Axial displacement proximity probe | N/A | Ø8 × 80 | 90 g | Turbomachinery monitoring |

| PR6423/10R-030 | Radial vibration proximity probe | N/A | Ø8 × 70 | 85 g | Shaft vibration detection |

| CON021/CON041 | Proximity sensor interface converter | 24 V DC | 22 × 110 × 90 | 150 g | Sensor signal processing |

| MMS6312 | 12-channel signal processor module | 24 V DC | 150 × 130 × 250 | 1.2 kg | Large-scale vibration monitoring systems |

| MMS6410 | Logic relay interface for MMS systems | 24 V DC | 120 × 130 × 160 | 950 g | Alarm relay control in MMS6000 systems |

| MMS6620 | High-frequency signal processing module | 24 V DC | 40 × 130 × 160 | 470 g | High-speed rotating machinery |

| MMS6800 | Dual-channel rack-mounted signal module | 24 V DC | 40 × 130 × 160 | 460 g | Industrial monitoring |

| MMS6700 | Modular chassis for MMS6000 modules | N/A | 483 × 133 × 350 | 6.2 kg | Rack-based sensor module housing |

FAQs (Q&A Format)

Q1: What type of sensors can be used with the MMS6822 module?

A1: The MMS6822 is compatible with eddy current proximity probes such as Epro PR6422 and PR6423. It supports both axial and radial measurement configurations.

Q2: Can I use the MMS6822 in hazardous areas?

A2: Yes, selected versions of the MMS6822 are ATEX-certified for use in hazardous environments. Ensure the model version includes the appropriate certification.

Q3: How do I configure the output signal type (Voltage vs. Current)?

A3: The output type can be configured via DIP switches or programmable software depending on the version. Refer to the user manual for detailed settings.

Q4: What is the calibration procedure for the MMS6822?

A4: Calibration involves connecting known input signals and verifying output readings against expected values. Adjust scaling factors as necessary using built-in calibration tools.

Q5: Does the MMS6822 support remote diagnostics?

A5: The base model does not include remote diagnostics. However, Epro offers advanced versions or companion modules that provide digital communication and remote health checks.

Q6: Is it possible to integrate the MMS6822 with existing DCS or PLC systems?

A6: Yes, the module provides standard analog output signals (±10 V or 4–20 mA) which can be connected to DCS, PLC, or SCADA systems for real-time monitoring and control.

Epro MMS6822 Interface Cards

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||