| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

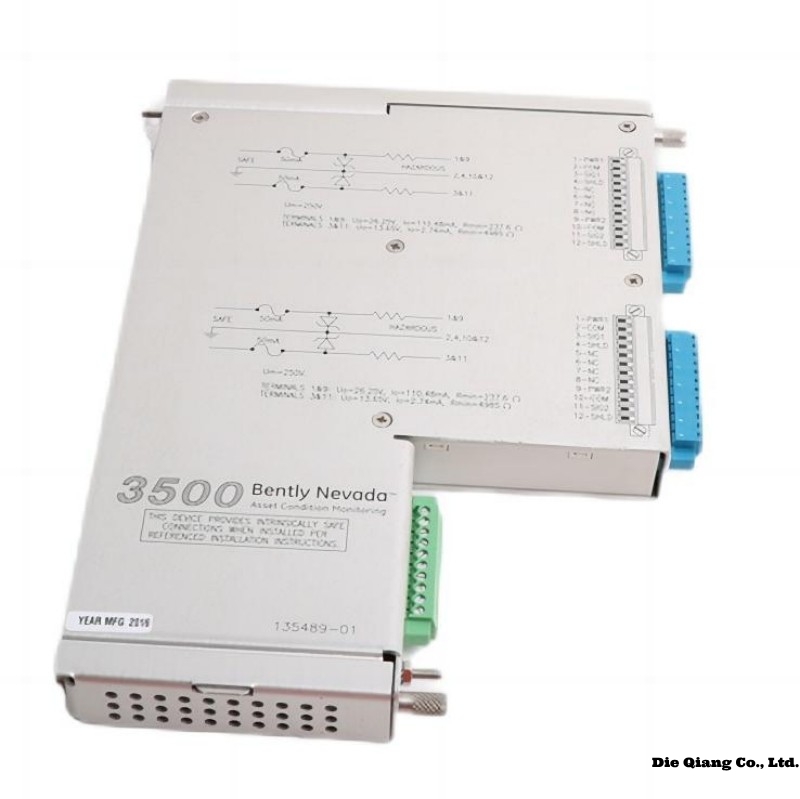

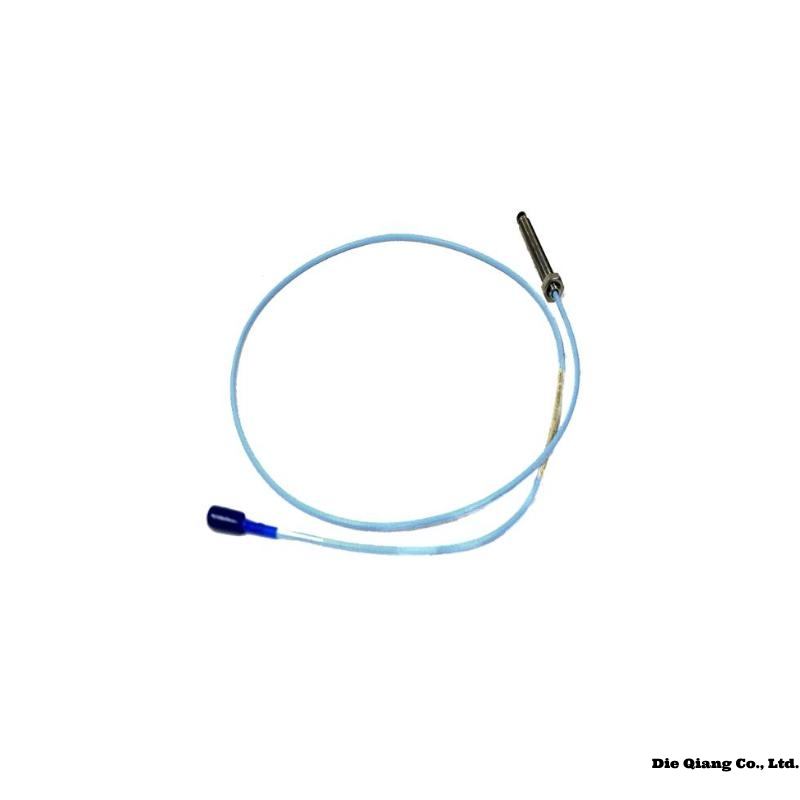

Product Introduction: Bently Nevada 330101-00-28-10-02-00

The Bently Nevada 330101-00-28-10-02-00 is a high-performance proximity probe designed for continuous vibration monitoring in rotating machinery. As part of the industry-renowned 3300 XL series, this proximity transducer system ensures high precision, durability, and reliability under challenging industrial environments.

Developed to meet API 670 standards, this proximity probe provides superior vibration detection, shaft position monitoring, and speed measurements. Its robust design and advanced signal integrity make it a staple in critical condition monitoring applications across power generation, oil and gas, petrochemical, and heavy manufacturing industries.

This specific model features a 28-inch probe cable, a 10-foot extension cable, and a 2-meter Proximitor sensor, offering maximum flexibility for installations in large-scale machines or hard-to-reach areas.

Product Advantages

-

API 670 Compliance: Fully complies with the American Petroleum Institute (API) 670 standard for machinery protection systems.

-

Enhanced Durability: Built with ruggedized materials for harsh industrial conditions including high temperatures, humidity, and vibration.

-

Wide Measurement Range: Enables accurate shaft vibration and position measurements across a broad dynamic range.

-

Modular Design: Interchangeable probe, extension cable, and Proximitor sensor for simplified installation and maintenance.

-

Proven Reliability: Trusted by global OEMs and end-users for dependable long-term performance in mission-critical machinery.

-

Electromagnetic Compatibility (EMC): Engineered for superior resistance against electrical noise and interference in noisy industrial environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-28-10-02-00 |

| Probe Length | 28 inches (711.2 mm) |

| Extension Cable Length | 10 feet (3.0 meters) |

| Proximitor Sensor Length | 2 meters (6.56 feet) |

| Power Supply Voltage | -24 VDC (nominal) |

| Output Voltage Range | -2 V to -18 V |

| Sensitivity | 200 mV/mil (7.87 mV/µm) |

| Linear Range | 80 mils (2 mm) |

| Non-Linearity | ±0.25 V within linear range |

| Operating Temperature | -35°C to +120°C (-31°F to +248°F) |

| Probe Tip Diameter | 5 mm |

| Material | AISI 303 Stainless Steel |

| Mounting Thread | 3/8-24 UNF |

| Weight | 0.323 kg |

| Cable length | 1 m |

| Enclosure Rating | IP65 (weather-resistant) |

| Connector Type | Miniature coaxial connector |

| EMC Compliance | EN 61000-6-2, EN 61000-6-4 |

Applications

-

Gas and Steam Turbines

-

Centrifugal Compressors

-

Axial Compressors

-

Electric Motors

-

Gearboxes

-

Pumps (Centrifugal, Reciprocating)

-

Blowers and Fans

-

Marine and Offshore Rotating Machinery

These sensors are widely used in preventive and predictive maintenance strategies to prevent catastrophic machinery failures and to optimize machine uptime.

Compatible Models

The 330101-00-28-10-02-00 is designed to be fully compatible with the following components from the Bently Nevada 3300 XL system:

-

Proximitor Sensor: 3300 XL 3300-XX-XX-XX-XX

-

Extension Cable: 3300 XL 330130-0M-XX-10-CN

-

Vibration Monitor Systems: 3500/42M, 3500/44M

-

Data Acquisition Systems: Bently Nevada System 1

-

Monitoring Racks: 3500 Series Full Rack Systems

-

Digital Transmitters: Bently Nevada Orbit 60 Series

Installation Instructions

-

Preparation:

Verify part numbers and ensure all components (probe, extension cable, Proximitor) are compatible. -

Probe Mounting:

Install the probe using the 3/8-24 UNF mounting thread. Ensure the probe is properly seated and secured with a lock nut or bracket. -

Gap Adjustment:

Use a target material to set the proper gap (typically 1 mm) between the probe tip and the shaft surface. -

Cable Routing:

Route the extension cable securely, avoiding sharp bends, heat sources, and areas with high EMI. -

Connection:

Connect the probe to the extension cable and the extension cable to the Proximitor sensor. Ensure all connections are tight and clean. -

Sensor Mounting:

Mount the Proximitor sensor on a vibration-free panel or enclosure, ensuring adequate ventilation. -

Calibration:

Calibrate the system using a micrometer target and reference voltage meter. Verify linear output range and sensitivity. -

Final Check:

Power up the system and verify voltage readings at rest and during shaft rotation. Compare with baseline data.

6 Related Models (Same Series or Functionality)

| Model Number | Description | Cable Length | Sensitivity | Linear Range |

|---|---|---|---|---|

| 330101-00-25-10-02-00 | 25” probe, 10’ ext., 2m Proximitor | 25 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

| 330101-00-20-10-02-00 | 20” probe, 10’ ext., 2m Proximitor | 20 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

| 330101-00-18-10-02-00 | 18” probe, 10’ ext., 2m Proximitor | 18 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

| 330101-00-12-10-02-00 | 12” probe, 10’ ext., 2m Proximitor | 12 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

| 330101-00-08-10-02-00 | 8” probe, 10’ ext., 2m Proximitor | 8 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

| 330104-00-10-10-02-00 | Reverse mount probe, 10’ ext., 2m Proximitor | 10 in / 10 ft | 200 mV/mil | 80 mils (2 mm) |

8 Popular Bently Nevada Models

| Model | Description | Cable Length | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|

| 330103-00-05-10-02-00 | 5 mm probe system, 10’ ext., 2m sensor | 5 in / 10 ft | -24 VDC | 95 × 30 × 30 mm | 420 g |

| 330104-00-05-10-02-00 | Reverse mount, 5 mm tip, standard cable | 5 in / 10 ft | -24 VDC | 100 × 30 × 30 mm | 430 g |

| 330130-040-00-00 | XL extension cable, 40 ft | 40 ft | N/A | N/A | 250 g |

| 330180-51-CN | High-temp cable assembly, armored | Custom | N/A | N/A | 500 g |

| 330106-05-30-10-02-00 | 3300 XL NSv system, 5 mm probe, 30 ft cable | 5 in / 30 ft | -24 VDC | 100 × 35 × 35 mm | 470 g |

| 330173-00-04-10-02-00 | NSv probe, small target, 4 mm tip | 4 in / 10 ft | -24 VDC | 85 × 28 × 28 mm | 400 g |

| 330500-02-00 | Velomitor piezo velocity sensor | N/A | 18–30 VDC | 60 mm × 30 mm diameter | 300 g |

| 3500/42M | 4-channel vibration monitor module | Rack mounted | 24 VDC | 240 × 24 mm (module) | 200 g |

FAQ (Frequently Asked Questions)

Q1: What is the maximum measurable shaft displacement with this probe system?

A1: The system has a linear range of 80 mils (2 mm) and is capable of accurately measuring shaft displacement within this range without exceeding non-linearity of ±0.25 V.

Q2: Is the 330101-00-28-10-02-00 suitable for high-temperature applications?

A2: Yes, the system can operate in environments ranging from -35°C to +120°C, making it suitable for most industrial high-temperature conditions.

Q3: Can the probe be installed in a reverse mounting configuration?

A3: This particular model is designed for forward mounting. For reverse mount applications, Bently Nevada offers specific models such as 330104-00-XX-XX.

Q4: How should the sensor gap be adjusted during installation?

A4: The gap should typically be adjusted to around 1 mm (40 mils) using a non-ferromagnetic micrometer target to ensure proper signal accuracy.

Q5: What monitoring systems is this probe compatible with?

A5: It is compatible with Bently Nevada’s 3500 Series Monitoring System, Orbit 60 Series, and System 1 software for full condition monitoring.

Q6: Can the components (probe, cable, sensor) be interchanged with other models?

A6: Yes, the modular design allows for interchangeability within the 3300 XL series, as long as the configuration (length and type) matches.

Bently Nevada 330101-00-28-10-02-00 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-28-10-02-00, Bently Nevada, Bently Nevada 330101-00-28-10-02-00