| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Bently Nevada 16710-30 Detailed Product Overview

Product Introduction

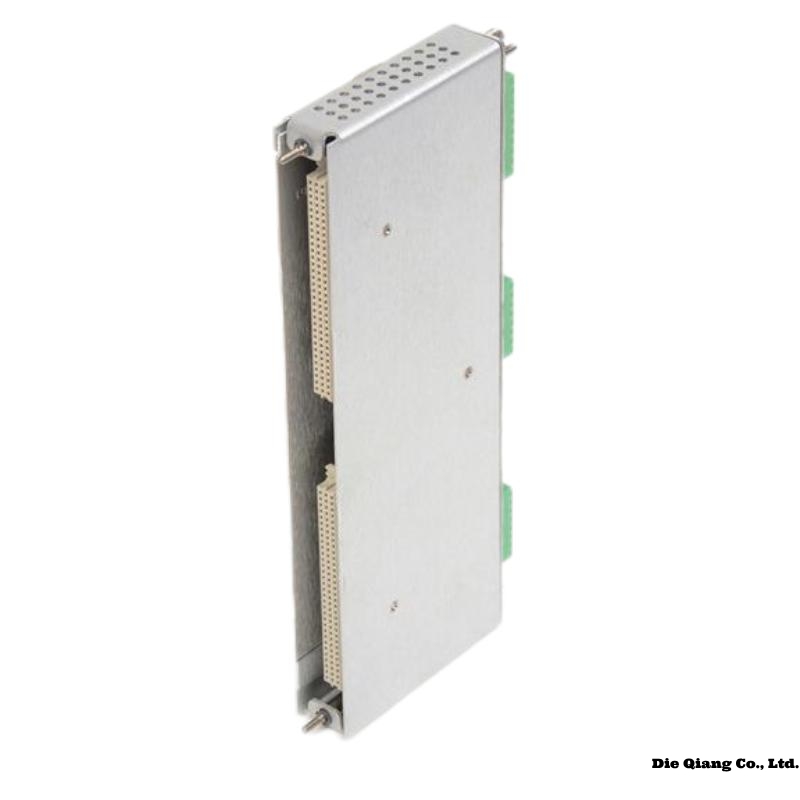

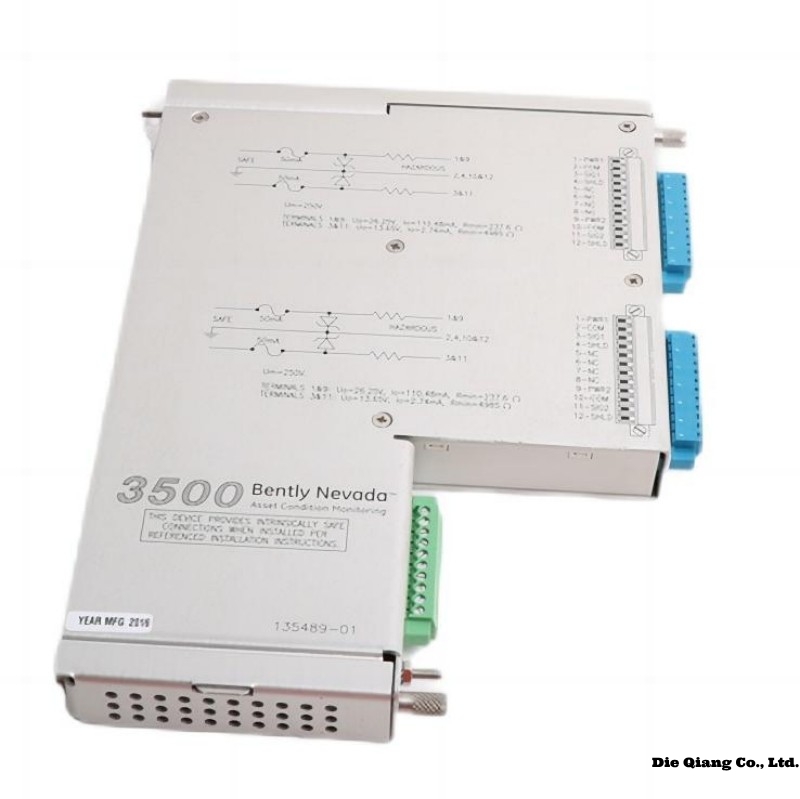

The Bently Nevada 16710-30 is a high-precision vibration monitoring and measurement module designed for use in industrial machinery protection systems. Manufactured by Bently Nevada, a globally recognized leader in condition monitoring and asset protection technologies, the 16710-30 is built to deliver exceptional performance in harsh environments. It is typically integrated into systems for monitoring critical rotating machinery such as turbines, compressors, and pumps.

This module is part of the advanced 16710 series, which is known for providing accurate dynamic signal measurement, real-time monitoring, and long-term trend data. The 16710-30 helps plant operators make informed decisions about machinery maintenance, thereby improving reliability and avoiding unplanned downtimes.

Product Advantages

-

High Measurement Accuracy: Offers precise vibration data with minimal signal distortion, ensuring reliable diagnostics for machinery health.

-

Industrial Durability: Engineered to withstand extreme industrial conditions including temperature variations, moisture, and high-vibration zones.

-

Seamless Integration: Easily integrates with Bently Nevada’s monitoring platforms, such as 3500 and 3300 series systems.

-

Real-Time Monitoring: Enables real-time alerts for anomalies, providing time for preventive maintenance.

-

Wide Application Range: Suitable for turbines, generators, compressors, and other high-speed rotating machinery.

-

Enhanced Safety and Compliance: Meets industrial safety and monitoring standards, supporting regulatory compliance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 16710-30 |

| Dimensions | 30 foot |

| Weight | 3 kg |

| Voltage Supply | +24 VDC nominal |

| Input Type | Dynamic (accelerometer or velocity sensor) |

| Output Signal | 4-20 mA, Buffered Signal |

| Frequency Response | 0.5 Hz to 20 kHz |

| Operating Temperature | -20°C to +70°C |

| Humidity Range | 0 to 95% non-condensing |

| Mounting Style | DIN rail or panel mount |

| Signal Conditioning | Integrated |

| Certification | CE, RoHS, CSA, ATEX compliant |

Product Applications

The Bently Nevada 16710-30 module is employed across various industrial domains for machinery protection and predictive maintenance. Typical application scenarios include:

-

Power Generation: Turbine vibration monitoring in thermal, nuclear, and hydroelectric plants.

-

Oil and Gas: Monitoring compressors, pumps, and gearboxes in upstream and downstream processes.

-

Petrochemical Industry: Used in refineries to monitor heavy-duty rotating equipment.

-

Manufacturing Plants: General-purpose machinery vibration monitoring to prevent costly breakdowns.

-

Aerospace Industry: Turbine testing facilities and maintenance environments.

Compatible Models

The 16710-30 module can be paired and integrated with various other Bently Nevada components and systems, including:

-

3500/42M Proximitor Monitor

-

3500/94 VGA Display Module

-

3300 XL Proximitor Sensor

-

3300/20 Dual Vibration Monitor

-

3500/22M Transient Data Interface

-

3500/25 Enhanced Keyphasor Module

Installation Instructions

-

Preparation:

-

Ensure power to the monitoring rack or panel is turned off.

-

Confirm module type and orientation.

-

-

Mounting:

-

Mount the 16710-30 on a DIN rail or panel using screws and brackets provided.

-

Maintain clearance for ventilation and wiring.

-

-

Wiring:

-

Connect dynamic signal inputs from sensors (accelerometers or velocity transducers).

-

Connect power supply cable (+24 VDC) to the appropriate terminal block.

-

Route buffered output and 4–20 mA signals to a data acquisition system or PLC.

-

-

Configuration:

-

Use Bently Nevada configuration software or system interface to assign measurement parameters.

-

Calibrate the module using reference signals or test equipment.

-

-

Verification:

-

Apply power and check LED indicators for status.

-

Perform functional test by simulating vibration signals and verifying outputs.

-

-

Final Check:

-

Secure wiring.

-

Document installation and settings for future maintenance.

-

Related Models in the Same Series

| Model | Description | Voltage | Dimensions (mm) | Weight (g) | Frequency Range |

|---|---|---|---|---|---|

| 16710-10 | Basic vibration monitor module | +24 VDC | 120×50×20 | 170 | 1 Hz – 10 kHz |

| 16710-20 | Enhanced version with buffered output | +24 VDC | 120×50×20 | 175 | 0.5 Hz – 15 kHz |

| 16710-40 | High-temp application model | +24 VDC | 125×52×22 | 185 | 0.5 Hz – 20 kHz |

| 16710-50 | For dual sensor input | +24 VDC | 130×50×22 | 200 | 0.3 Hz – 18 kHz |

| 16710-60 | For integration with relay modules | +24 VDC | 120×50×20 | 180 | 0.5 Hz – 20 kHz |

| 16710-70 | Extended range and advanced diagnostics | +24 VDC | 130×55×25 | 190 | 0.2 Hz – 25 kHz |

Popular Bently Nevada Models

| Model | Description | Voltage | Dimensions (mm) | Weight (g) | Application |

|---|---|---|---|---|---|

| 3500/42M | Proximitor Monitor | +24 VDC | 120×40×25 | 210 | Shaft vibration and position monitoring |

| 3300 XL | Proximitor Sensor Series | Passive | Varies | 150–250 | Proximity probe systems |

| 3500/22M | Transient Data Interface | +24 VDC | 130×50×20 | 180 | Real-time data acquisition |

| 3500/25 | Enhanced Keyphasor Module | +24 VDC | 110×40×20 | 170 | Speed and phase reference |

| 190501 | Velocity Transducer | Passive | 100×35×35 | 220 | General vibration monitoring |

| 330103-00-05-10-02 | Proximity Probe | Passive | Probe length 80–200 | 180–250 | Rotating machinery |

| 330180-91-00 | Extension Cable | Passive | Length: 5m–9m | 300–600 | Probe to sensor cable |

| 3500/15 | Power Supply Module | 120/240 VAC | 150×60×35 | 300 | System power management |

FAQs (Q&A)

Q1: What is the primary function of the Bently Nevada 16710-30?

A1: The primary function of the 16710-30 is to monitor dynamic signals from vibration sensors and provide accurate measurements for machinery protection and performance analysis.

<br>

Q2: Can the 16710-30 be used in high-temperature environments?

A2: Yes, it is designed to operate in temperatures ranging from -20°C to +70°C, making it suitable for most industrial environments.

<br>

Q3: What types of sensors are compatible with this module?

A3: The module is compatible with standard dynamic sensors such as accelerometers and velocity transducers used in vibration monitoring.

<br>

Q4: How is the module powered and what is the input voltage requirement?

A4: The 16710-30 operates on a +24 VDC power supply, which should be regulated and supplied according to industrial standards.

<br>

Q5: Does the module require calibration after installation?

A5: Yes, calibration is recommended post-installation to ensure measurement accuracy and to configure the measurement parameters based on the application.

<br>

Q6: What monitoring systems is this module compatible with?

A6: The 16710-30 integrates seamlessly with Bently Nevada’s 3500 and 3300 series systems, enabling centralized monitoring and diagnostics.

<br>

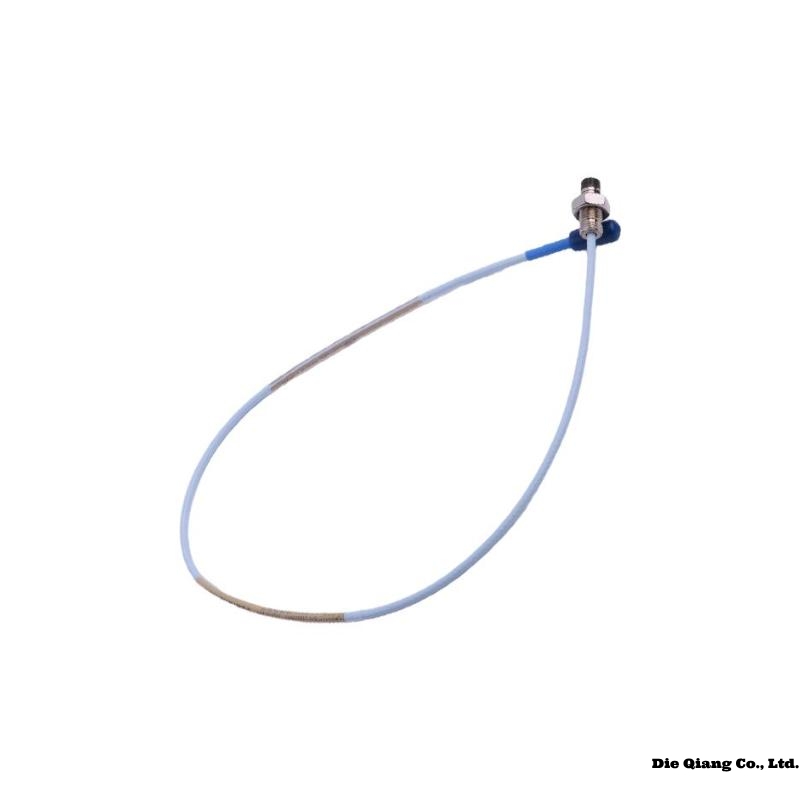

Bently Nevada 16710-30 16710 Interconnect Cable

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||