| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

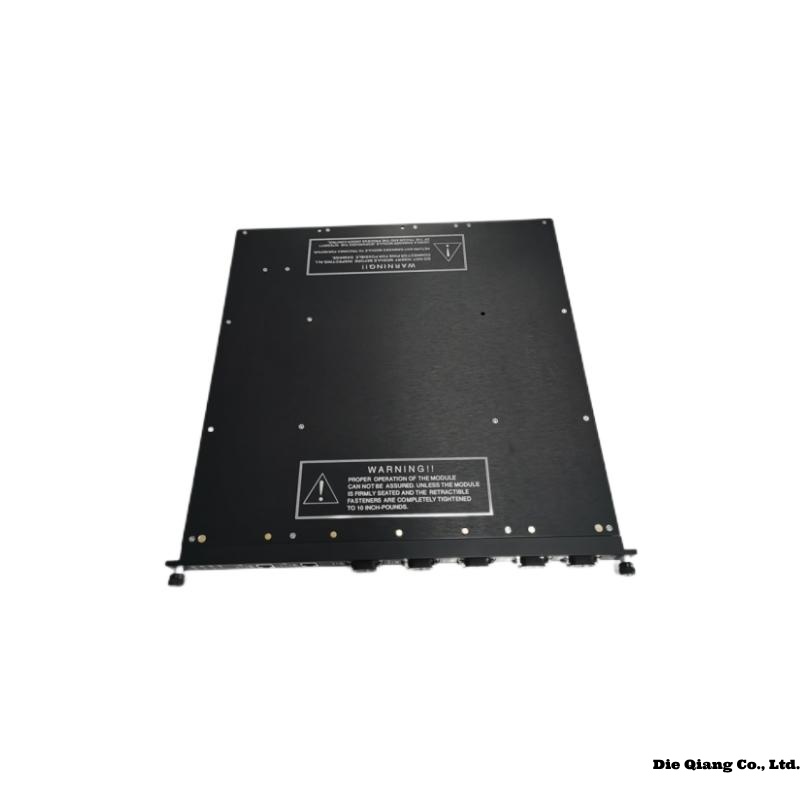

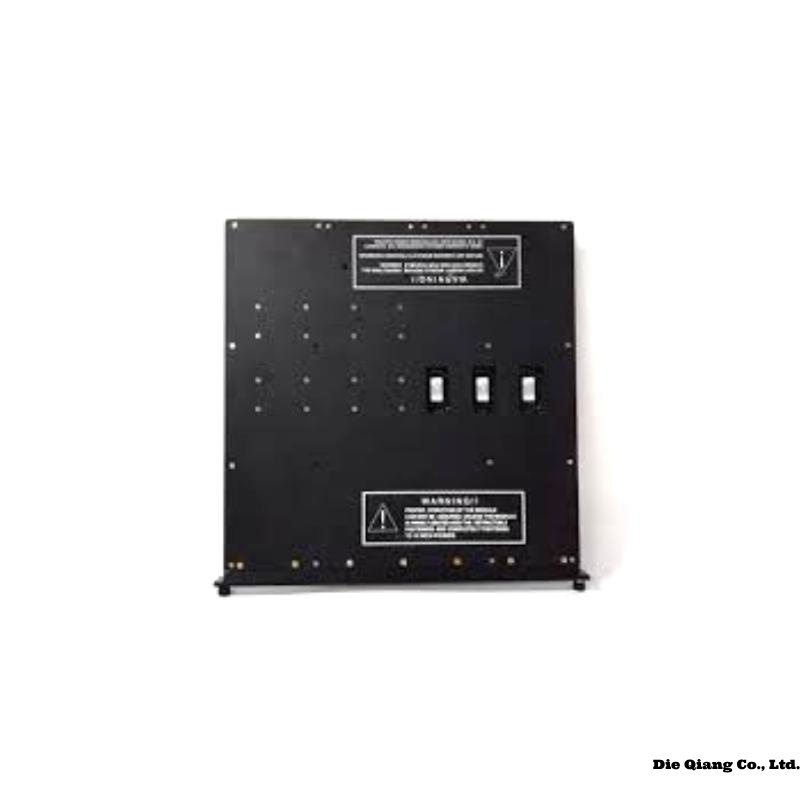

Triconex 3614E Product Overview

The Triconex 3614E is a high-performance safety system module designed for critical control applications. It is part of the Triconex Safety Instrumented System (SIS) family, which is widely used in industries requiring fail-safe operation, such as oil & gas, chemical processing, and power generation. The 3614E module is known for its reliability, fault tolerance, and robust design, making it ideal for safety-critical environments.

Product Advantages

-

High Reliability – Designed with triple modular redundancy (TMR) technology to ensure continuous operation even in the event of a failure.

-

Fault Tolerance – Automatically detects and compensates for failures without interrupting system performance.

-

Wide Operating Range – Suitable for harsh industrial environments with extended temperature and humidity ranges.

-

Easy Integration – Compatible with various Triconex systems and third-party devices for seamless system expansion.

-

Certified Safety Standards – Complies with IEC 61508 and SIL 3 standards, ensuring high safety integrity.

-

Long Service Life – Built with industrial-grade components for extended durability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 3614E |

| Dimensions | 114.3 ×127 × 107.95 mm |

| Weight | 1.5 kg |

| Operating Voltage | 24V DC (±10%) |

| Power Consumption | 15W (max) |

| Operating Temp. | -20°C to +70°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Certifications | SIL 3, IEC 61508, ATEX (optional) |

| Communication | Ethernet, RS-485, Modbus |

| Redundancy | Triple Modular Redundancy (TMR) |

Applications

The Triconex 3614E is widely used in industries where safety and reliability are critical:

-

Oil & Gas – Emergency shutdown systems (ESD), fire & gas detection.

-

Chemical Processing – Process shutdown and safety interlocks.

-

Power Generation – Turbine control and reactor protection.

-

Pharmaceuticals – Batch process safety management.

-

Mining – Hazardous environment monitoring.

Compatible & Recommended Models

The Triconex 3614E can be used alongside the following modules for a complete safety system:

-

Triconex 3624T – Digital Input Module

-

Triconex 3704A – Analog Input Module

-

Triconex 3805E – Communication Module

-

Triconex 4351B – Power Supply Module

-

Triconex 3008 – Main Processor Module

-

Triconex 3481 – Relay Output Module

Recommended Related Models (Same Series)

| Model | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| Triconex 3624T | Digital Input | 24V DC | 150×120×75 mm | 1.1 kg | TMR Technology |

| Triconex 3704A | Analog Input | 24V DC | 150×120×75 mm | 1.3 kg | High Accuracy |

| Triconex 3805E | Comm Module | 24V DC | 150×120×75 mm | 1.0 kg | Ethernet/RS-485 |

| Triconex 4351B | Power Supply | 120/240V AC | 200×150×80 mm | 2.5 kg | Dual Redundancy |

| Triconex 3008 | Main Processor | 24V DC | 180×140×90 mm | 1.8 kg | SIL 3 Certified |

| Triconex 3481 | Relay Output | 24V DC | 150×120×75 mm | 1.2 kg | High Current Rating |

Top 8 Popular Triconex Models (Other Series)

| Model | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| Triconex Trident | Safety Controller | 24V DC | 300×200×150 mm | 5.0 kg | Advanced Diagnostics |

| Triconex 3503E | Analog Output | 24V DC | 150×120×75 mm | 1.1 kg | High Precision |

| Triconex 3664 | Digital Output | 24V DC | 150×120×75 mm | 1.0 kg | Fast Response |

| Triconex MP3008 | Main Processor | 24V DC | 180×140×90 mm | 1.8 kg | High-Speed Processing |

| Triconex 4409 | Power Supply | 120/240V AC | 200×150×80 mm | 2.5 kg | Redundant Input |

| Triconex 4239 | Communication | 24V DC | 150×120×75 mm | 1.0 kg | Modbus TCP/IP |

| Triconex 2601 | I/O Module | 24V DC | 150×120×75 mm | 1.1 kg | Compact Design |

| Triconex 4009 | System Chassis | N/A | 400×300×200 mm | 8.0 kg | Modular Expansion |

Installation Instructions

-

Mounting – Install the module in a 19-inch rack or DIN rail using the provided brackets.

-

Wiring – Connect power and signal cables according to the terminal labeling (follow the manual for correct polarity).

-

Grounding – Ensure proper grounding to avoid electrical noise interference.

-

Power-Up – Verify voltage before turning on the system (24V DC ±10%).

-

Configuration – Use Tristation 1131 software to configure the module parameters.

-

Testing – Perform a diagnostic test to confirm proper operation before full deployment.

FAQ (Frequently Asked Questions)

Q1: What is the difference between Triconex 3614E and 3624T?

A1: The 3614E is a general-purpose safety module with TMR, while the 3624T is a digital input module designed for sensor interfacing.

Q2: Can the 3614E operate in extreme temperatures?

A2: Yes, it supports -20°C to +70°C, making it suitable for harsh environments.

Q3: Is the 3614E compatible with non-Triconex systems?

A3: It can interface via Modbus or Ethernet, but optimal performance is achieved within the Triconex ecosystem.

Q4: What certifications does the 3614E have?

A4: It is SIL 3 certified per IEC 61508 and optionally ATEX for hazardous areas.

Q5: How often should the 3614E be maintained?

A5: Annual diagnostics are recommended, but it has self-monitoring for real-time fault detection.

Q6: Can I replace the 3614E while the system is running?

A6: Yes, it supports hot-swapping if the system is configured for redundancy.

Triconex 3614E Module monitoring DO components

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

![]()

![]()

![]()

![]()