| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

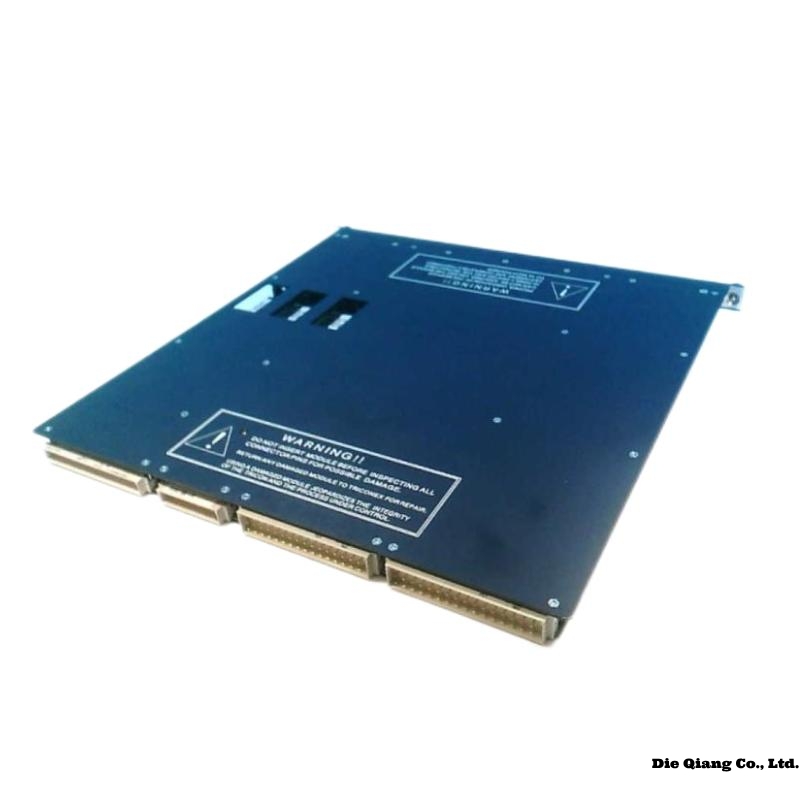

Product Introduction: Triconex 3502EN2

The Triconex 3502EN2 is a high-performance safety module designed for critical control applications in industrial environments. It is part of the Triconex Tricon series, which is widely recognized for its reliability and fault-tolerant architecture. The 3502EN2 module is specifically engineered to provide robust safety solutions for industries such as oil and gas, power generation, and chemical processing.

This module is built to meet stringent safety standards, ensuring uninterrupted operation even in harsh conditions. Its advanced diagnostics and redundancy features make it a preferred choice for safety instrumented systems (SIS).

Product Advantages

-

High Reliability: The 3502EN2 incorporates triple-modular redundancy (TMR) technology, ensuring continuous operation even in the event of a hardware failure.

-

Advanced Diagnostics: Real-time monitoring and diagnostics reduce downtime and improve maintenance efficiency.

-

Fault Tolerance: Designed to handle faults seamlessly without compromising system performance.

-

Wide Operating Temperature Range: Suitable for extreme industrial environments.

-

Compliance with Safety Standards: Meets IEC 61508 and other international safety standards.

-

Easy Integration: Compatible with other Triconex modules and systems for seamless expansion.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 3502EN2 |

| Dimensions | 129.5 x 75 x 114.5 mm |

| Weight | 0.5 kg |

| Operating Voltage | 24V DC (±10%) |

| Power Consumption | 10W max |

| Operating Temperature | -40°C to +70°C |

| Communication Protocol | Modbus, Ethernet/IP |

| Redundancy | Triple Modular Redundancy (TMR) |

| Certifications | IEC 61508, SIL 3 |

Product Applications

The Triconex 3502EN2 is widely used in industries requiring high safety integrity levels, including:

-

Oil & Gas: For emergency shutdown systems (ESD) and fire & gas detection.

-

Power Generation: In turbine control and boiler protection systems.

-

Chemical Processing: For process shutdown and safety interlocks.

-

Pharmaceuticals: In critical batch processing controls.

-

Mining: For conveyor belt safety and ventilation control.

Compatible & Recommended Models

The 3502EN2 can be used alongside the following Triconex modules for a complete safety solution:

-

Triconex 3503E – Digital Input Module

-

Triconex 3504E – Digital Output Module

-

Triconex 3505E – Analog Input Module

-

Triconex 3506E – Analog Output Module

-

Triconex 3507E – Communication Module

-

Triconex 3508E – Power Supply Module

Recommended Related Models (Same Series)

| Model | Function | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| Triconex 3501E | Main Processor Module | 24V DC | 160 x 120 x 60 | 0.7 |

| Triconex 3503E | Digital Input Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 3504E | Digital Output Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 3505E | Analog Input Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 3506E | Analog Output Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 3507E | Communication Module | 24V DC | 150 x 100 x 50 | 0.5 |

Popular Triconex Models (Other Series)

| Model | Function | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| Triconex 3620 | Safety Controller | 24V DC | 200 x 150 x 80 | 1.2 |

| Triconex 3721 | I/O Module | 24V DC | 150 x 100 x 50 | 0.6 |

| Triconex 3805E | Communication Gateway | 24V DC | 180 x 120 x 60 | 0.9 |

| Triconex 4351B | Power Supply | 120V AC | 200 x 100 x 70 | 1.0 |

| Triconex 4409 | Analog Input Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 4609 | Digital Output Module | 24V DC | 150 x 100 x 50 | 0.5 |

| Triconex 4805 | Network Interface Module | 24V DC | 160 x 120 x 60 | 0.8 |

| Triconex 4909 | Safety Relay Module | 24V DC | 150 x 100 x 50 | 0.6 |

Installation Instructions

-

Power Off: Ensure the system is powered down before installation.

-

Mounting: Secure the module in the designated slot within the Triconex chassis.

-

Wiring: Connect the power supply (24V DC) and I/O signals as per the wiring diagram.

-

Grounding: Properly ground the module to avoid electrical noise interference.

-

Power On: After installation, power up the system and verify module status via diagnostics.

-

Testing: Perform a functional test to ensure proper operation.

Refer to the official Triconex installation manual for detailed guidelines.

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the Triconex 3502EN2?

A1: It is a safety module designed for fault-tolerant control in critical industrial applications.

Q2: What redundancy technology does the 3502EN2 use?

A2: It utilizes Triple Modular Redundancy (TMR) for high reliability.

Q3: Can the 3502EN2 operate in extreme temperatures?

A3: Yes, it operates within a range of -40°C to +70°C.

Q4: Is the 3502EN2 compliant with safety standards?

A4: Yes, it meets IEC 61508 and is SIL 3 certified.

Q5: What industries commonly use the 3502EN2?

A5: Oil & gas, power generation, chemical processing, and pharmaceuticals.

Q6: Can the 3502EN2 be integrated with other Triconex modules?

A6: Yes, it is compatible with various I/O and communication modules in the Triconex series.

Triconex 3502EN2 Digital Input Modules

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

![]()

![]()

![]()