| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

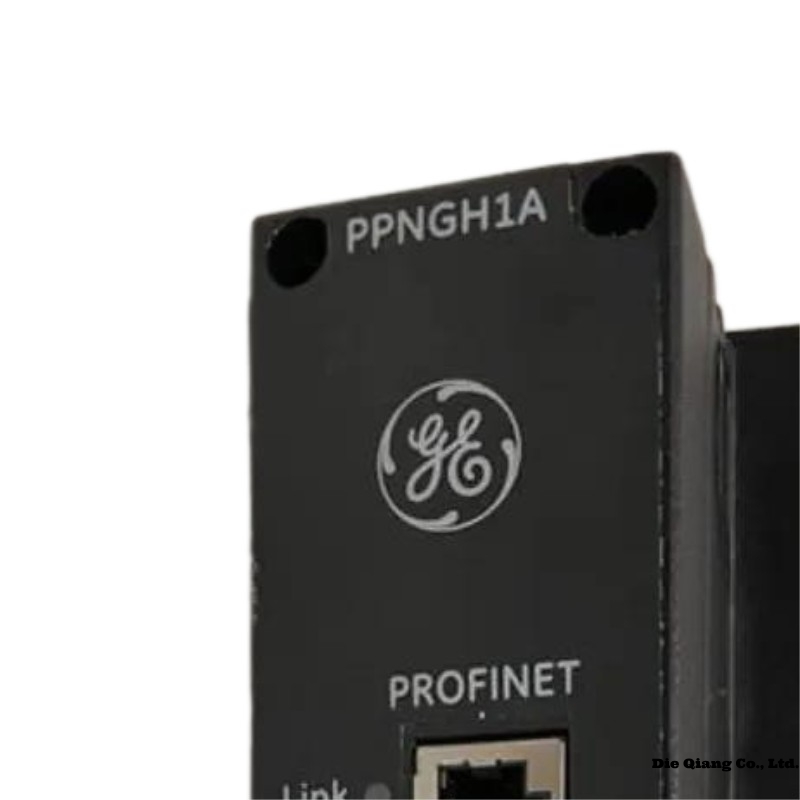

GE IS420PPNGH1A Product Overview

The GE IS420PPNGH1A is a high-performance PPN (Precision Pressure Node) Input Module designed for use within the GE Mark VIe and Mark VIeS control systems. It serves as a critical component in the monitoring and control of pressure signals within complex industrial processes. The module delivers precise analog-to-digital signal conversion, enabling accurate and reliable data collection necessary for safe and efficient operations. Engineered with rugged construction, the IS420PPNGH1A ensures exceptional durability even in demanding environments, maintaining stable performance over a long operational lifespan.

This module is hot-swappable, which minimizes system downtime during maintenance activities, and features advanced diagnostic capabilities to enhance system troubleshooting and predictive maintenance strategies. With seamless integration into GE’s control platforms, the IS420PPNGH1A supports high system availability, making it a trusted choice for industries such as power generation, oil & gas, and manufacturing.

Key Advantages of GE IS420PPNGH1A

-

High Precision Measurement: Delivers exceptional accuracy for pressure signal readings, ensuring reliable process control.

-

Robust and Durable Design: Built to operate reliably in harsh industrial environments with resistance to vibration, temperature fluctuations, and electrical interference.

-

Hot-Swappable: Allows module replacement without shutting down the system, minimizing production losses.

-

Advanced Diagnostics: Supports predictive maintenance with built-in fault detection and status indicators.

-

Seamless Integration: Fully compatible with Mark VIe and VIeS control platforms, supporting easy deployment and system expansion.

-

Enhanced Safety Compliance: Designed to meet strict industry standards for critical control applications.

Technical Specifications of GE IS420PPNGH1A

| Parameter | Specification |

|---|---|

| Dimensions | 330.2 x 101.6 mm |

| Weight | 0.8 kg |

| Operating Voltage | 24 V DC (nominal) |

| Power Consumption | 5 W |

| Input Signal Type | Analog Pressure Input |

| Input Channels | Single-channel |

| Input Range | 0 to 500 psi (adjustable) |

| Resolution | 16-bit ADC |

| Accuracy | ±0.1% of full scale |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 5% to 95% non-condensing |

| Protection Class | IP20 |

| Mounting | DIN-rail or panel mounting |

| Communication Protocol | Ethernet (for diagnostics and control data) |

Application Areas of GE IS420PPNGH1A

-

Power Generation Plants: Steam turbine, gas turbine, and combined cycle pressure monitoring.

-

Oil & Gas Facilities: Pipeline pressure monitoring, refining operations.

-

Chemical Processing Plants: Reactor and vessel pressure control.

-

Water Treatment Systems: Pressure management in filtration and pumping stations.

-

Industrial Manufacturing: Pressure measurement in automated production lines.

-

Aerospace Testing: Engine pressure monitoring and test facilities.

Compatible Models and Integration

The GE IS420PPNGH1A is designed to work seamlessly with the following modules and systems:

-

Mark VIe Controller IS420UCSCH1A

-

Mark VIe I/O Pack IS420ESWBH1A

-

Mark VIe Communication Module IS420UCSBH4A

-

Mark VIeS Safety Controller IS420UCSBH3A

-

Mark VIe Analog Input Module IS420AIICH1A

-

Mark VIe Digital Input Module IS420DIICH1A

Installation Instructions

-

Preparation: Ensure that power to the system is safely isolated before installation.

-

Mounting: Secure the IS420PPNGH1A onto a standard DIN rail or directly to the control cabinet panel using the provided mounting slots.

-

Wiring: Connect the pressure signal input to the designated terminal block. Follow proper grounding and shielding practices to prevent noise interference.

-

Power Connection: Connect the 24 VDC power supply ensuring polarity is correctly observed.

-

Networking: Attach Ethernet communication cables if diagnostic data monitoring is required.

-

Verification: Double-check all connections, ensuring tightness and accuracy before reapplying system power.

-

System Configuration: Configure the input range and calibration settings via the Mark VIe ToolboxST software.

-

Testing: Conduct signal and diagnostic tests to verify proper operation before final commissioning.

Recommended Related Models (Same Series or Compatible)

| Model Number | Description | Dimensions (mm) | Weight (kg) | Voltage |

|---|---|---|---|---|

| IS420AIICH1A | Analog Input Module | 150×50×120 | 0.8 | 24 V DC |

| IS420UCSCH1A | Controller Module | 180×60×140 | 1.2 | 24 V DC |

| IS420ESWBH1A | Ethernet Switch Module | 150×50×120 | 0.7 | 24 V DC |

| IS420STCIH1A | Thermocouple Input Module | 150×50×120 | 0.9 | 24 V DC |

| IS420TRISH1A | Trip Relay Output Module | 150×50×120 | 1.0 | 24 V DC |

| IS420ERIOH1A | Ethernet Remote I/O Module | 180×60×130 | 1.1 | 24 V DC |

8 Popular GE Models

| Model Number | Description | Dimensions (mm) | Weight (kg) | Voltage |

|---|---|---|---|---|

| IS420UCSBH4A | Mark VIe Controller | 180×60×140 | 1.2 | 24 V DC |

| DS200TCQAG1B | Mark V Turbine Control Board | 330×250×50 | 1.8 | 5 V DC, 15 V DC |

| DS200PCCAG5ACB | Drive Control Power Interface Card | 200×120×30 | 0.5 | 24 V DC |

| IS420VRTDH1B | RTD Input Module | 150×50×120 | 0.8 | 24 V DC |

| DS200LDCCH1A | LAN Communications Controller Card | 310×220×30 | 1.5 | 5 V DC |

| IS200TBTCH1CBB | Terminal Board | 150×100×30 | 0.6 | N/A (Passive) |

| IS200VCMIH1B | VME Bus Master Interface Board | 330×250×50 | 1.9 | 5 V DC |

| IS200DSPXH1D | Digital Signal Processor Module | 180×120×40 | 0.9 | 24 V DC |

FAQ – Frequently Asked Questions

Q1: What type of input signals does the IS420PPNGH1A accept?

A1: The IS420PPNGH1A accepts analog pressure input signals, typically in the range of 0 to 500 psi, with adjustable configurations.

Q2: Can the IS420PPNGH1A module be hot-swapped during system operation?

A2: Yes, the IS420PPNGH1A supports hot-swapping, allowing replacement without the need to power down the entire system.

Q3: How do I configure the IS420PPNGH1A after installation?

A3: Configuration is performed using the GE ToolboxST software, where users can set input ranges, scaling, and diagnostic parameters.

Q4: What environments is the IS420PPNGH1A suitable for?

A4: It is ideal for industrial environments, including high-vibration, high-temperature, and electrically noisy conditions.

Q5: What safety standards does the IS420PPNGH1A comply with?

A5: The module adheres to industry safety standards applicable to pressure monitoring systems in critical control applications.

Q6: What maintenance is required for the IS420PPNGH1A?

A6: Minimal maintenance is needed. Periodic visual inspection and functional testing are recommended to ensure ongoing reliability.

GE IS420PPNGH1A PROFINET Controller Gateway Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||