| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

GE IC200PWB001 Power Distribution Module

Product Introduction

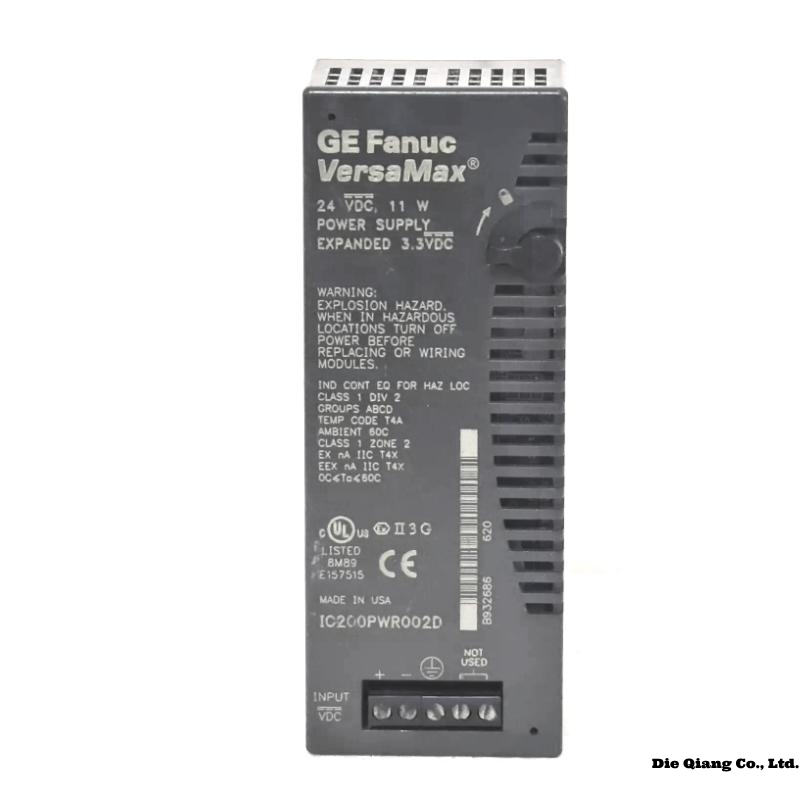

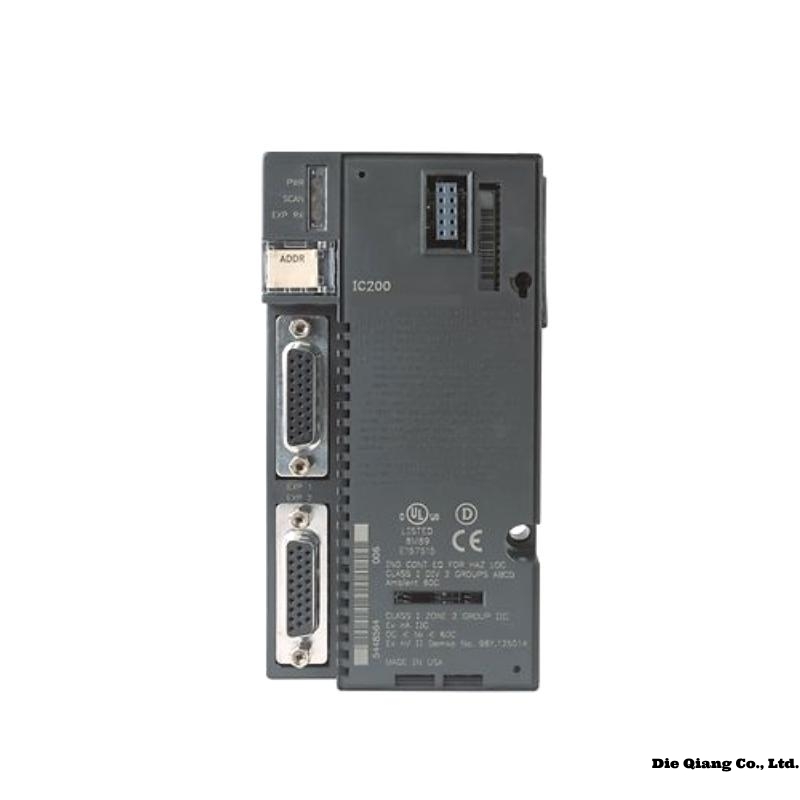

The GE IC200PWB001 is a power distribution backplane module designed for the VersaMax PLC system. Engineered by General Electric (GE), this module plays a pivotal role in distributing power across I/O modules mounted on the backplane. It serves as a centralized interface that simplifies wiring and enhances power management in modular control system architectures.

This module is part of the VersaMax I/O family, which is well-regarded for its flexibility, compact size, and robust performance in industrial environments. The IC200PWB001 is typically used in conjunction with a power supply and several I/O modules, providing power and communication pathways through the backplane bus.

The IC200PWB001 is ideal for small to mid-sized automation systems that demand modular scalability, efficient power management, and reliable operation in challenging industrial settings.

Product Advantages

-

Efficient Power Distribution: Enables streamlined power delivery to all attached I/O modules on the rack.

-

Modular Design Compatibility: Designed to seamlessly integrate with VersaMax modular systems, allowing flexible system expansion.

-

Reduced Wiring Complexity: Minimizes the need for individual wiring connections, simplifying installation and maintenance.

-

Industrial Durability: Engineered to operate reliably in high-vibration, temperature-variant industrial environments.

-

Compact Footprint: The small size ensures optimal use of panel space without compromising performance.

-

Plug-and-Play Integration: Easily integrates into the existing VersaMax configuration without requiring special configurations or software.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | IC200PWB001 |

| Product Type | Power Distribution Backplane Module |

| Compatible System | GE VersaMax PLC System |

| Input Voltage | 24 VDC nominal |

| Voltage Range | 20 – 30 VDC |

| Current Capacity | Up to 3 Amps (total across modules) |

| Dimensions | 66.8 × 133.4 × 70 mm |

| Weight | 0.35 kg |

| Mounting Type | DIN Rail or Panel Mount |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Relative Humidity | 5% to 95% non-condensing |

| Agency Approvals | UL, CE, cUL, Class 1 Div 2 (HazLoc) |

| Backplane Support | Supports up to 7 I/O modules |

| Communication Support | Via Backplane Bus |

Product Applications

-

Factory Automation: Used in programmable logic control systems for discrete manufacturing environments.

-

Process Control Systems: Suitable for continuous process industries such as oil & gas, chemical, and pharmaceutical sectors.

-

Material Handling Systems: Integrated in automated conveyor systems, robotic arms, and sorting systems.

-

Water and Wastewater Management: Used in pump control, level monitoring, and automated treatment plant systems.

-

Building Automation: Controls lighting, HVAC, and access systems in smart building environments.

-

Packaging Machinery: Powers modular I/O for controlling sensors and actuators in high-speed packaging lines.

Compatible Models

The GE IC200PWB001 is commonly used in conjunction with the following VersaMax components:

-

IC200CHS002 – 7-slot I/O Carrier Base

-

IC200PWR102 – 24VDC Power Supply

-

IC200MDL650 – 16-point Discrete Input Module

-

IC200MDL740 – 16-point Discrete Output Module

-

IC200ALG320 – 4-Channel Analog Input Module

-

IC200ALG264 – 4-Channel Analog Output Module

-

IC200CPU001 – VersaMax CPU for control processing

Each of these modules connects directly or indirectly through the power distribution provided by the IC200PWB001 backplane.

Installation Instructions

-

Safety First: Ensure all power to the system is disconnected before beginning installation.

-

Mounting: Mount the IC200PWB001 to a DIN rail or directly onto a control panel using appropriate screws and mounting brackets.

-

Connection to Power Supply: Connect the 24VDC power source to the designated power input terminals. Ensure polarity is correct and securely fastened.

-

Module Alignment: Align the module with other VersaMax I/O modules or carrier bases and slide into place to establish backplane connectivity.

-

Secure Modules: Once inserted, secure the modules using mechanical latches or screws provided.

-

Power On: Restore system power and verify the module LED indicators for proper operation.

-

System Test: Run initial diagnostics through the PLC or HMI to confirm correct communication and power distribution.

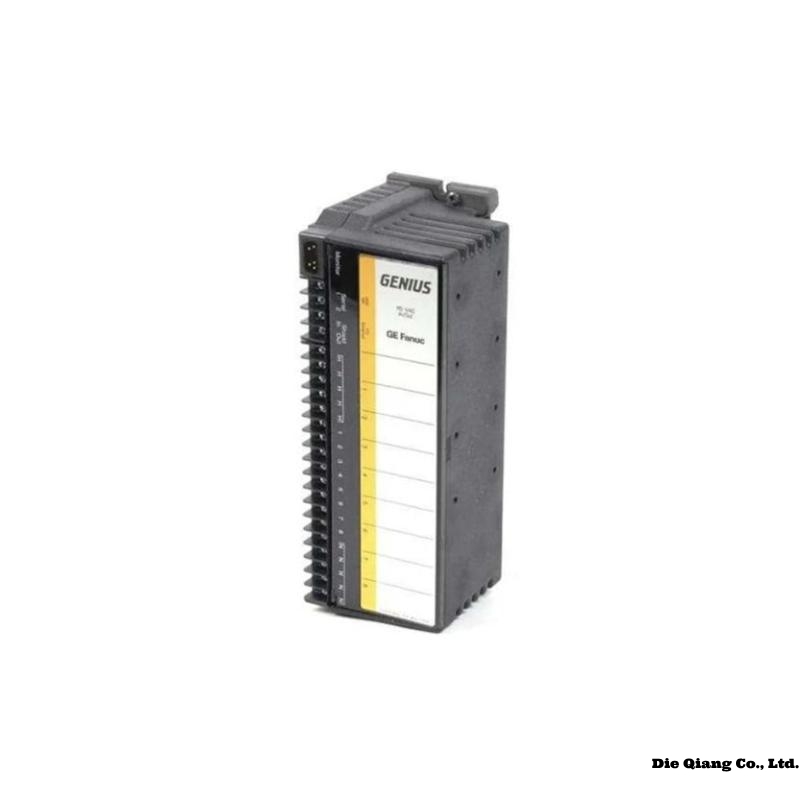

6 Related Models from the Same Series

| Model | Description | Voltage | Current | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| IC200PWR102 | 24VDC Power Supply Module | 24VDC | 3.5A | 110 x 100 x 60 | 200g |

| IC200CHS002 | 7-slot I/O Carrier Base | — | — | 130 x 180 x 50 | 250g |

| IC200ALG320 | Analog Input Module, 4 Channels | 24VDC | — | 90 x 140 x 50 | 180g |

| IC200MDL640 | 16-point Discrete Input Module | 24VDC | — | 90 x 140 x 50 | 160g |

| IC200MDL740 | 16-point Discrete Output Module | 24VDC | 0.5A/pt | 90 x 140 x 50 | 165g |

| IC200ERM002 | Ethernet Remote I/O Master Module | 24VDC | — | 90 x 140 x 50 | 190g |

8 Popular GE Models and Specifications

| Model Number | Description | Voltage | Current | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| IC200PWR101 | Power Supply, 120/240 VAC Input | 120/240VAC | 0.5A | 110 x 100 x 60 | 220g |

| IC695CPU310 | RX3i CPU, 1GHz Processor | 3.3V/5VDC | — | 135 x 150 x 70 | 350g |

| IC693MDL645 | 32-point DC Input Module | 24VDC | — | 130 x 140 x 50 | 180g |

| IC693MDL734 | 16-point Relay Output Module | 120/240VAC | 2A/pt | 130 x 140 x 50 | 200g |

| IC695CHS012 | RX3i 12-slot Universal Backplane | — | — | 300 x 180 x 60 | 400g |

| IC693ALG391 | 2-Channel Analog Output Module | 24VDC | — | 110 x 140 x 50 | 160g |

| IC695PSA140 | RX3i Power Supply, 100-240VAC Input | 100-240VAC | 5A | 150 x 160 x 70 | 420g |

| IC200CPUE05 | VersaMax Micro CPU, 14 I/O, Ethernet | 24VDC | — | 130 x 140 x 60 | 260g |

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the GE IC200PWB001?

A1: The IC200PWB001 serves as a backplane module that distributes power to connected VersaMax I/O modules and provides a communication interface across the rack.

<br>

Q2: Can this module be used without a separate power supply?

A2: No, the IC200PWB001 requires a compatible external 24VDC power supply like the IC200PWR102 to function properly.

<br>

Q3: How many modules can I connect to one IC200PWB001?

A3: The module typically supports up to 7 additional I/O modules depending on total current consumption and power supply capacity.

<br>

Q4: Is this module suitable for use in hazardous environments?

A4: Yes, it is approved for use in Class I Division 2 hazardous locations, provided it is installed in accordance with GE guidelines.

<br>

Q5: How do I know if the IC200PWB001 is operating correctly?

A5: LED indicators on the connected modules and system diagnostic tools in the PLC software can verify that the backplane is distributing power and data correctly.

<br>

Q6: Can I use this module in a redundant configuration?

A6: While the module itself does not support redundancy, the VersaMax system can be configured with redundant CPUs and power supplies to enhance reliability.

<br>

GE IC200PWB001 VersaMax Power Booster

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||